Precision surface grinding machine

A surface grinder, precision technology, applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problems of high efficiency, low noise, accidents, and easy production that cannot meet the requirements of surface grinders. Achieve the effect of reducing equipment failure rate and personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

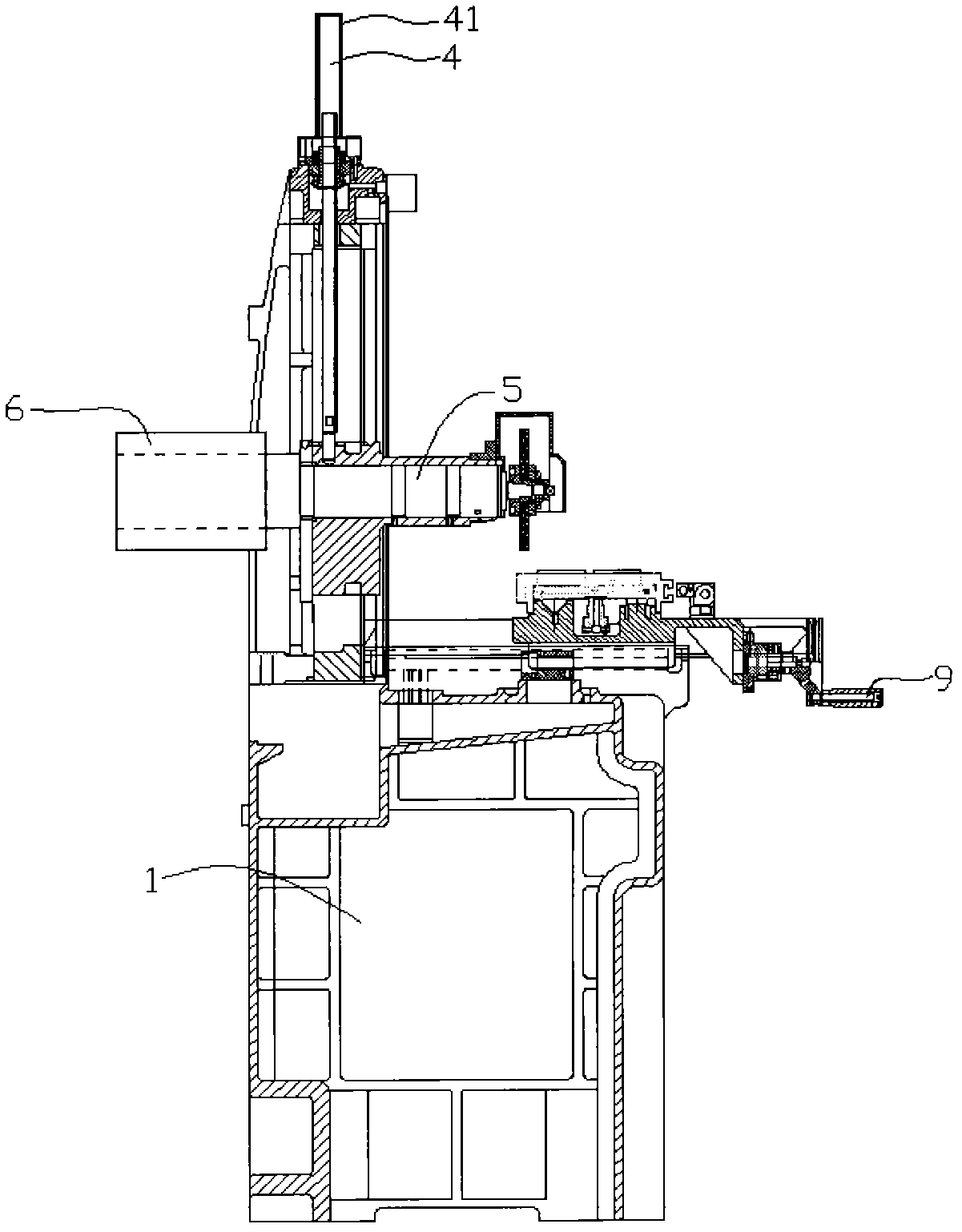

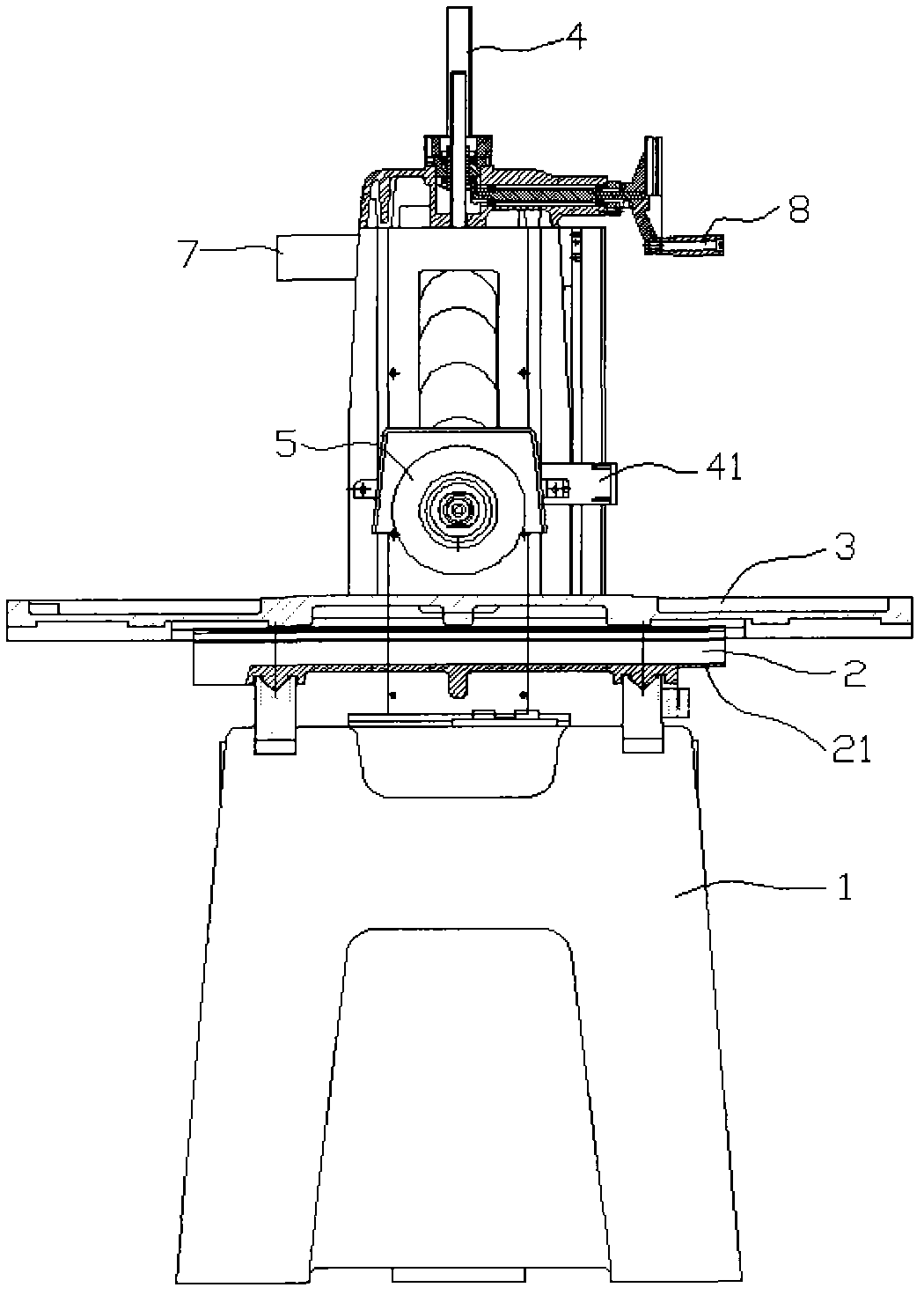

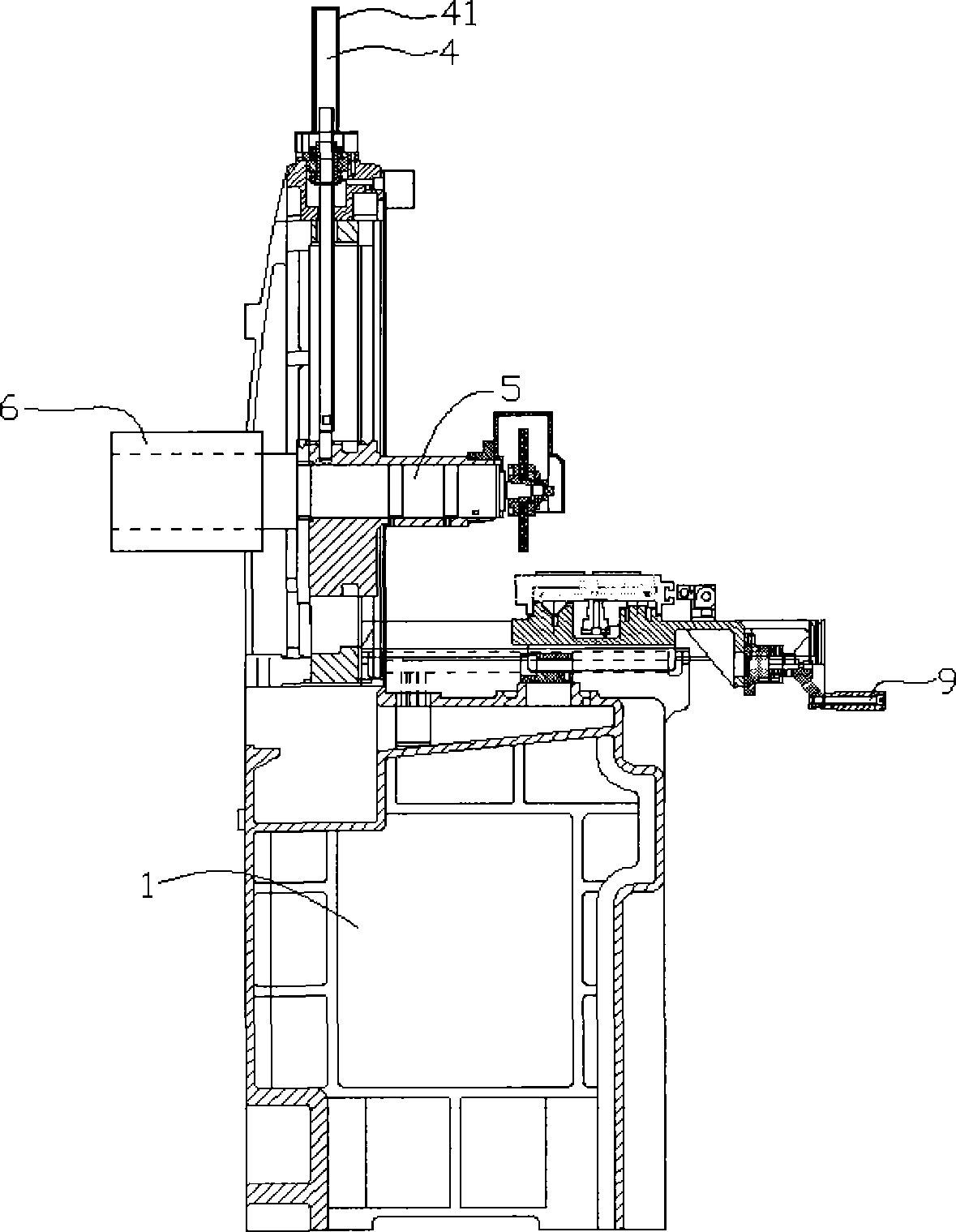

[0033] Please refer to figure 1 with figure 2 , The present invention provides a precision surface grinder, comprising a body bottom barrel 1, a saddle 2, a workbench 3, a column 4, a spindle 5, a grinding wheel 6, an automatic lubrication system (not shown) and a display screen 7.

[0034] Please refer to figure 1 with figure 2 , the saddle 2 is arranged above the bottom bucket 1 of the fuselage, the workbench 3 is arranged above the saddle 2, the column 4 is connected with the workbench 3 through a main shaft 5, and the main shaft One end of 5 is erected on the workbench 3, the other end passes through the column 4, the grinding wheel 6 is installed on the end of the main shaft 5 close to the column 4, the automatic lubrication system (not shown) Installed in the bottom barrel 1 of the fuselage, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com