Husking machine

A sheller and frame technology, applied in the field of sheller, can solve the problems of large straightener wear, flying dust, short service life of sheller wheels, etc., to ensure cleaning, reduce wear, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

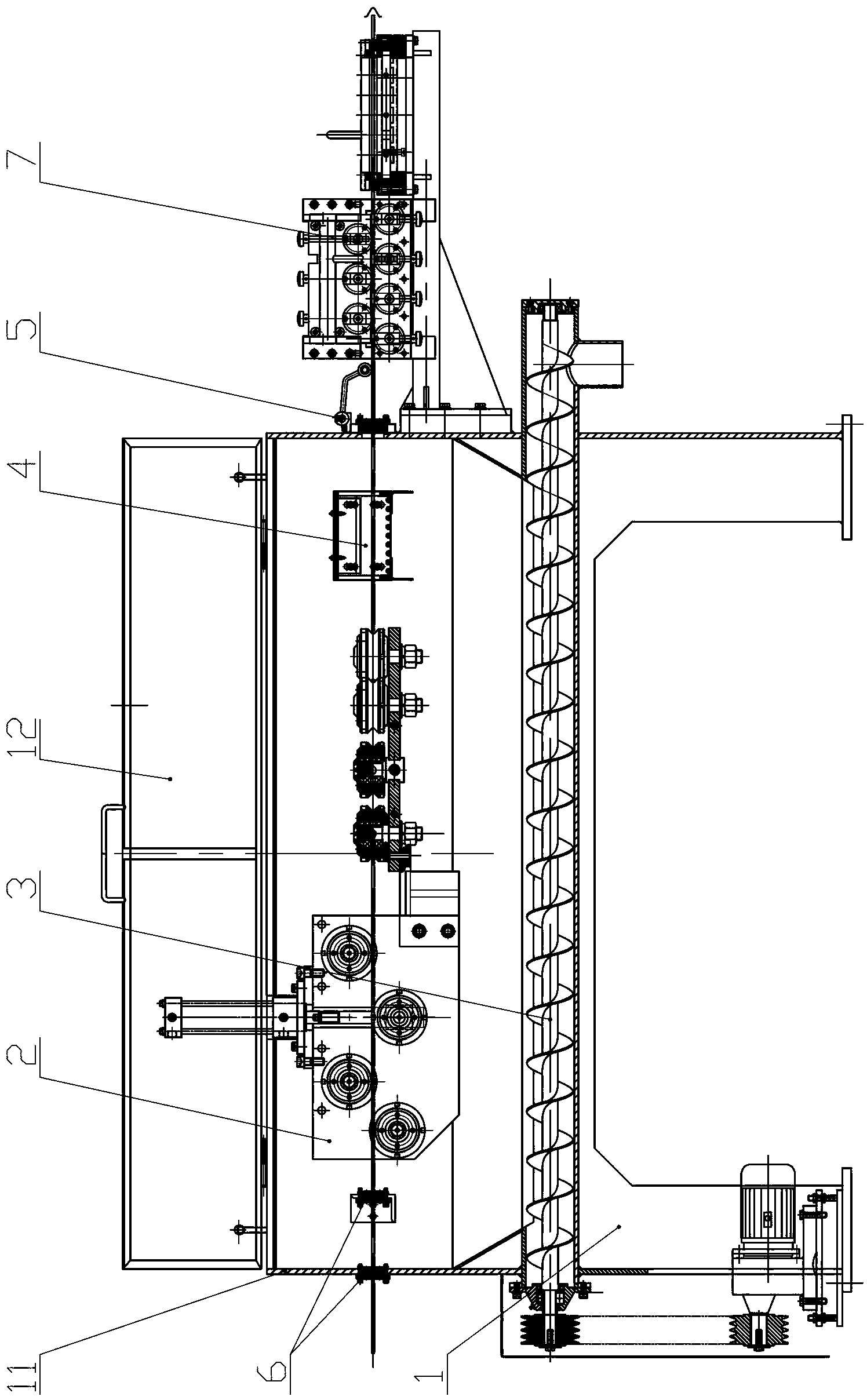

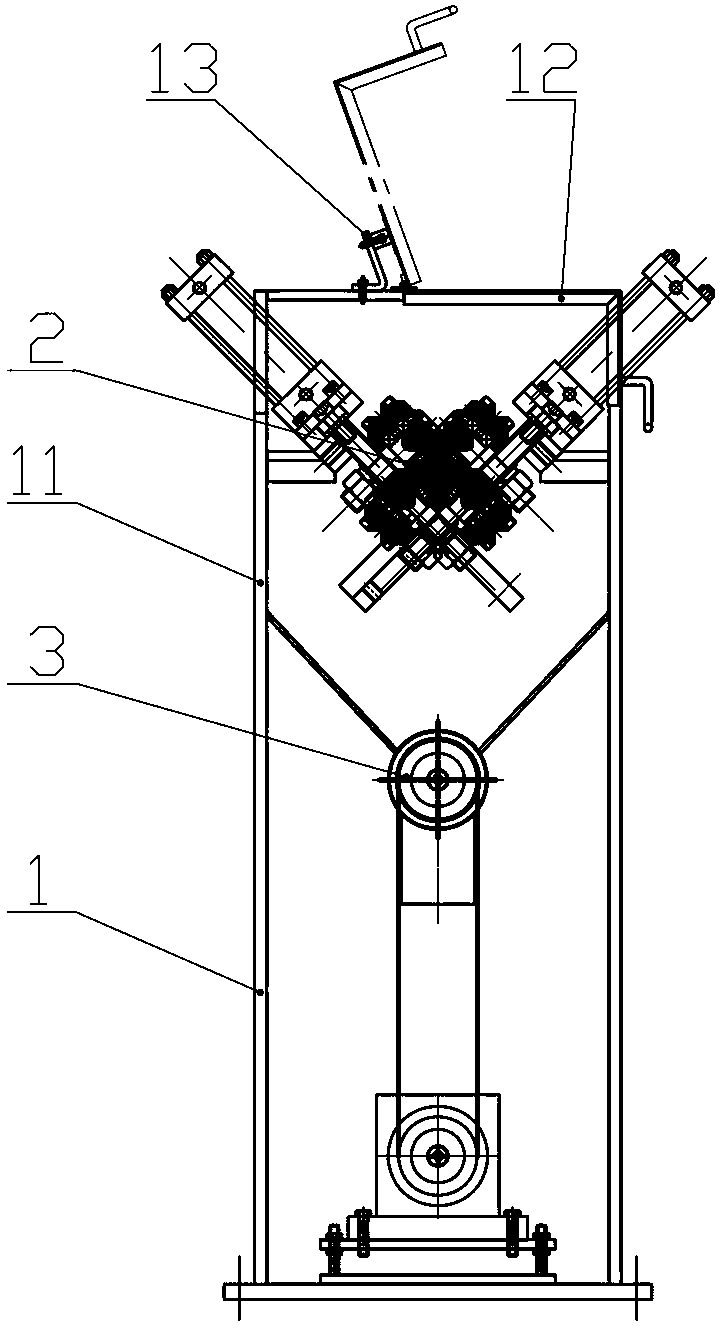

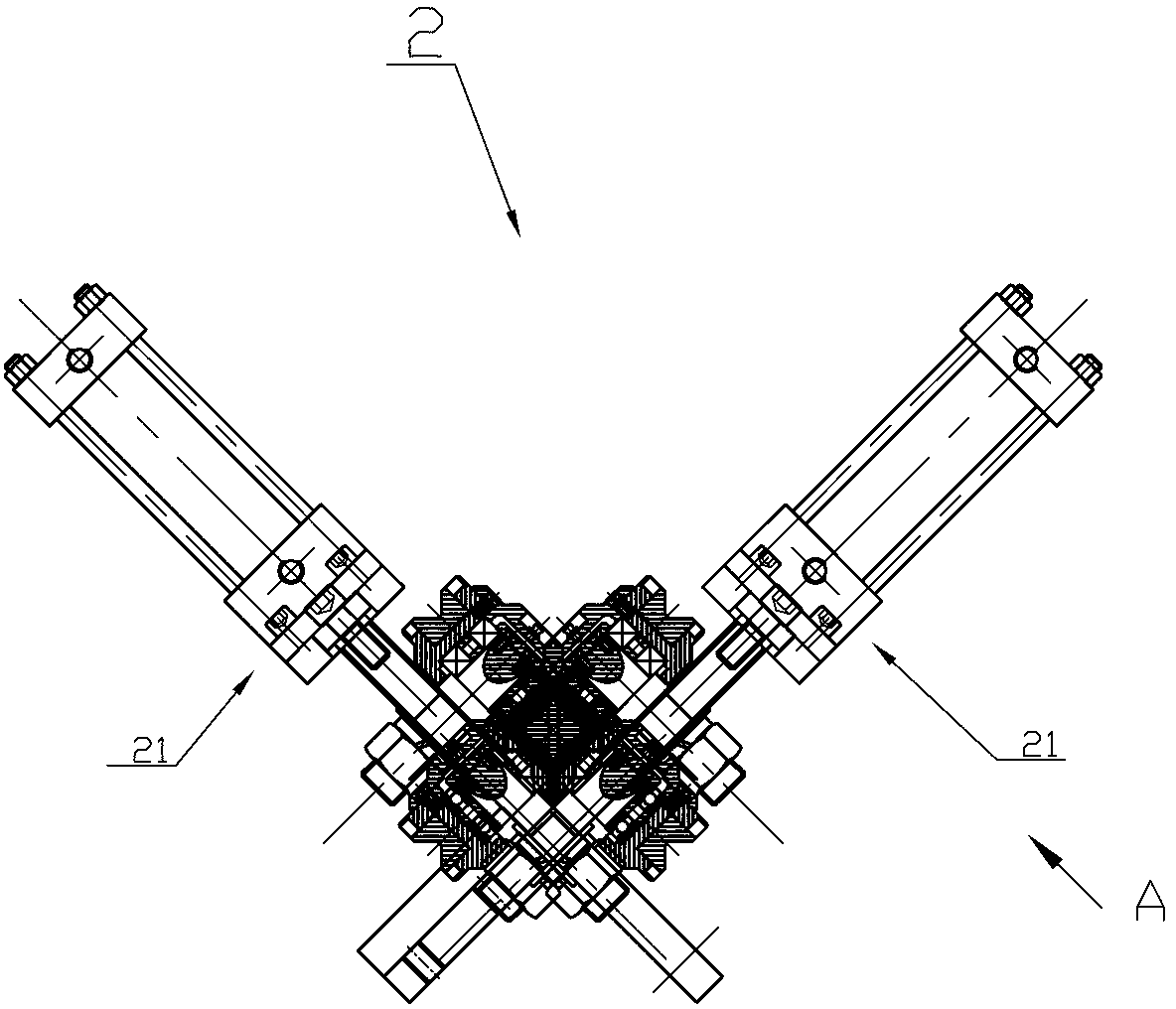

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Figure 1~Figure 11 Among them, it includes a frame 1, a box body 11, a flip cover 12, a support frame 13, a shelling device 2, a four-wheel shelling mechanism 21, a bracket 22, a fixed plate 23, a wire wheel 24, a connecting plate 25, a driving element 26, Chute 27, slider 28, slag discharge device 3, shaft pulley 301, motor pulley 302, front end cover 303, front bearing 304, housing 305, slag inlet 306, rear bearing 307, rear end cover 308, rotating Shaft 309, blade 310, slag outlet 311, reduction motor 312, belt 313, motor bottom plate 314, adjustment screw 315, adjustment seat 316, shaft pin 317, fixed block 318, cover 319, ash removal device 4, fixed frame 41, Box body 42, gland 43, ash removal medium 44, vertical groove 45, ash outlet 46, handle 47, insert plate 48, thread pressing device 5, pressing rod 51, fixed block 52, rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com