Lifting handle

A handle and handle seat technology, which is applied in the direction of wing leaf handles, applications, door/window accessories, etc., can solve the problems of ineffective cushioning, inability to meet the needs of consumers, and inability of the handle to return completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

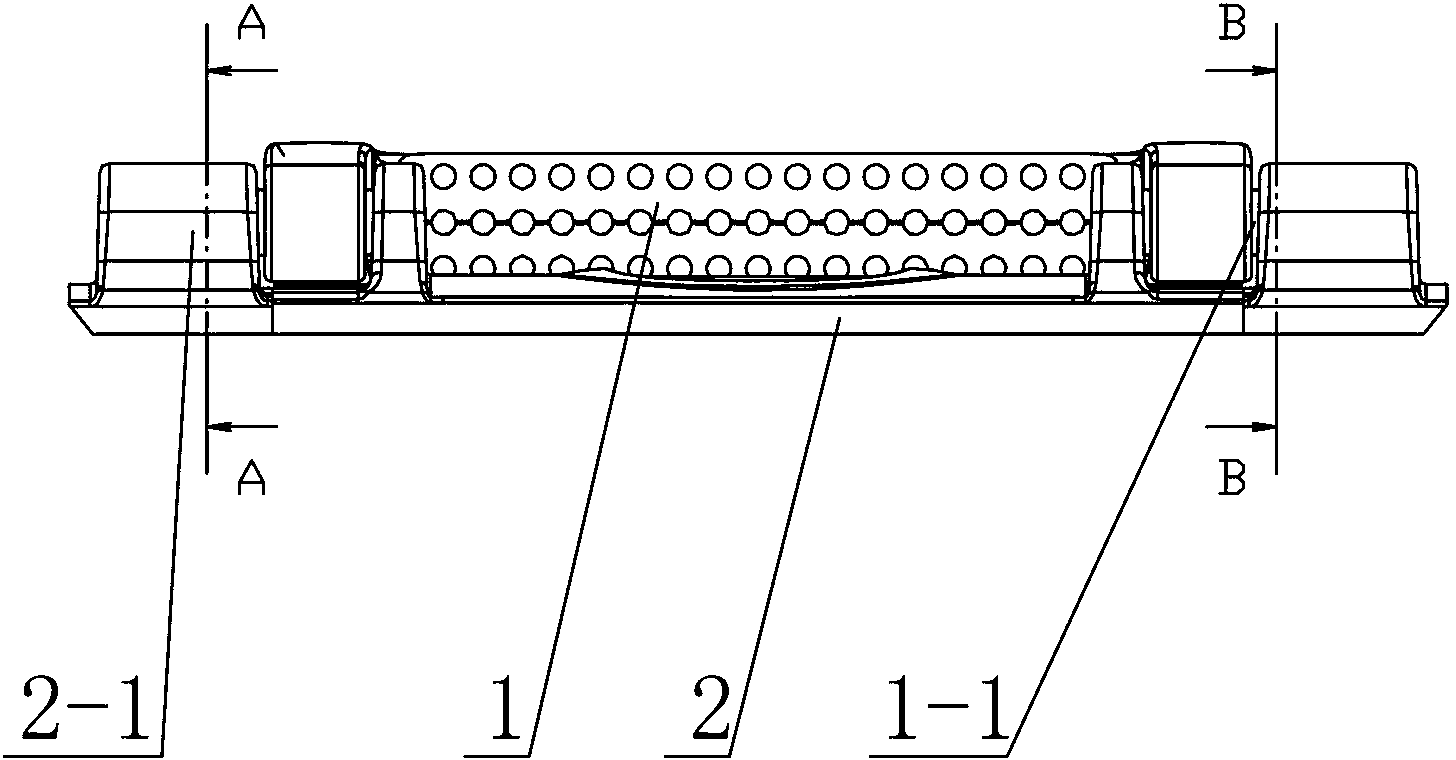

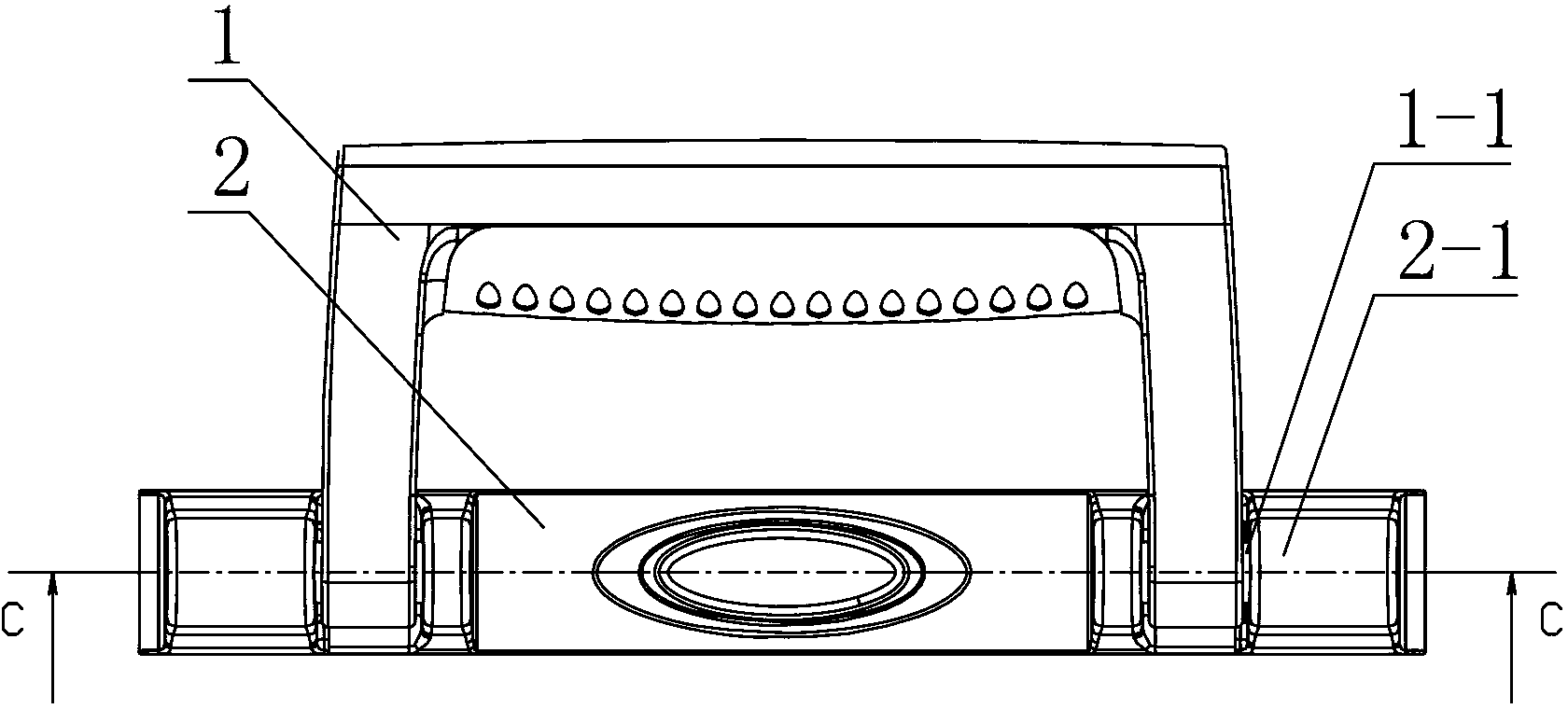

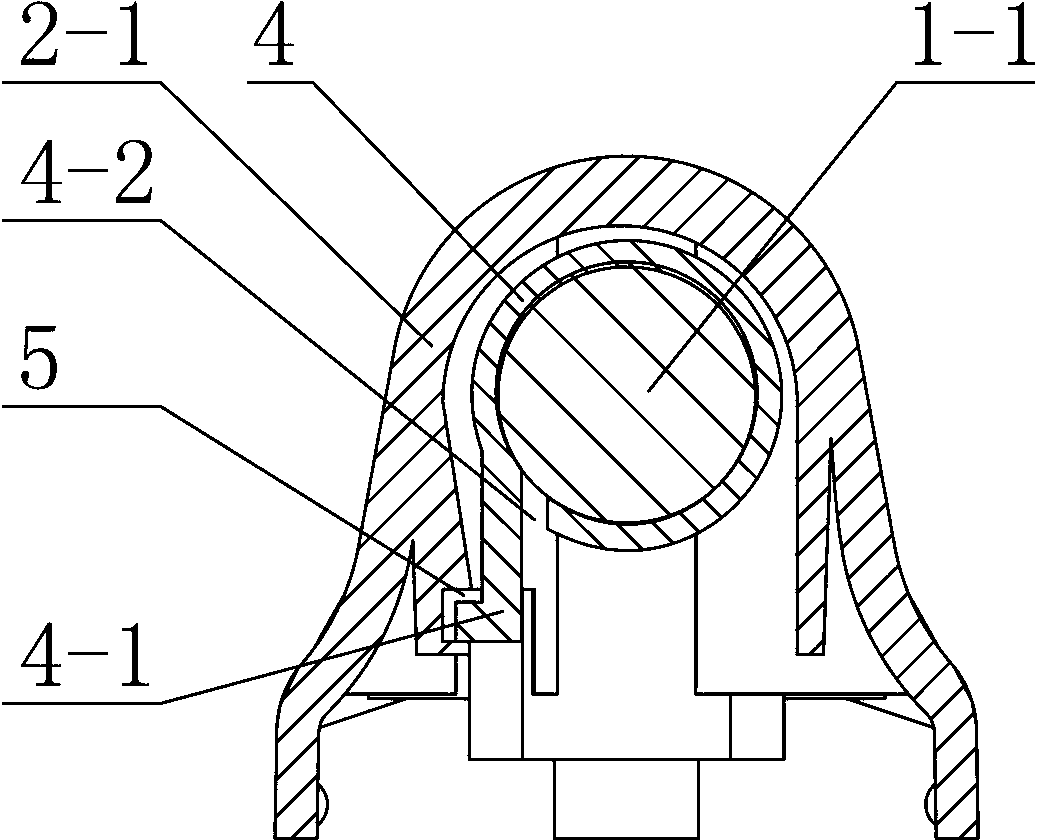

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the specific embodiment provided by the present invention is a handle, including a handle 1 and a handle base 2, the lower end of the handle 1 is provided with a connecting column 1-1, the handle base 2 is provided with a connecting sleeve 2-1, and the connecting column 1 -1 cooperates with the connecting sleeve 2-1 to realize the rotatable connection between the lower end of the handle 1 and the handle seat 2, which is characterized in that: the connecting column 1-1 of the handle 1 is provided with a return spring 3, and the return spring 3 is located at the handle 1 connection Between the column 1-1 and the connecting sleeve 2-1 of the handle seat 2, and the return spring 3 provides the elastic force for the handle 1 to fit back, and the other side of the handle 1 is connected to the column 1-1 and the connecting sleeve 2-1 of the handle sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com