Coil winding machine for large power three-phase stator coils

A three-phase stator and winding machine technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of large rotation volume, affecting work efficiency, poor coil consistency, etc., to avoid repeated loading and unloading, improve Production efficiency, the effect of avoiding frequent replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

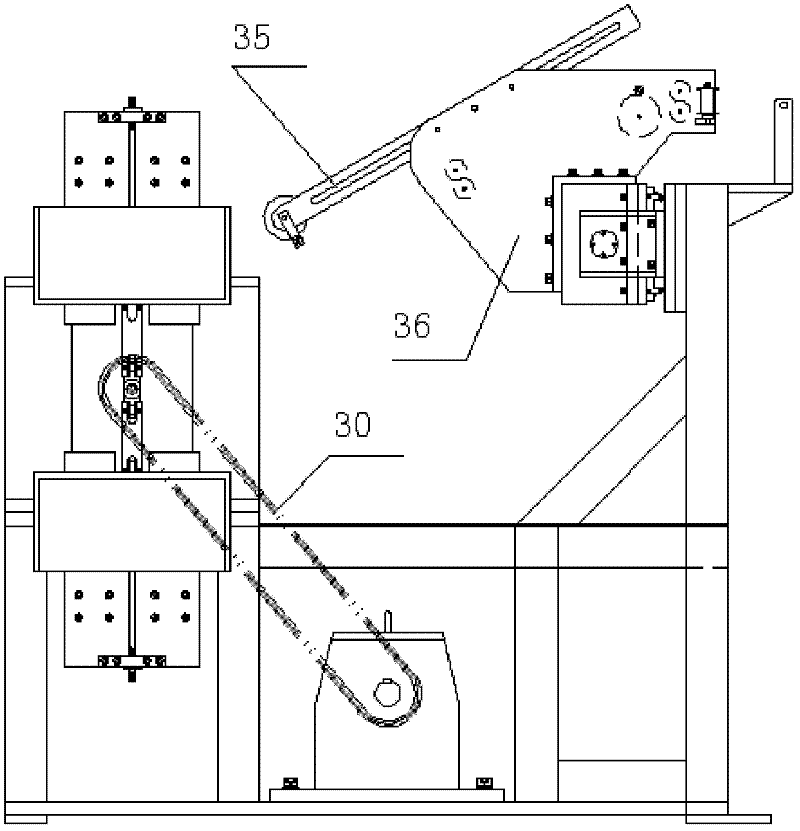

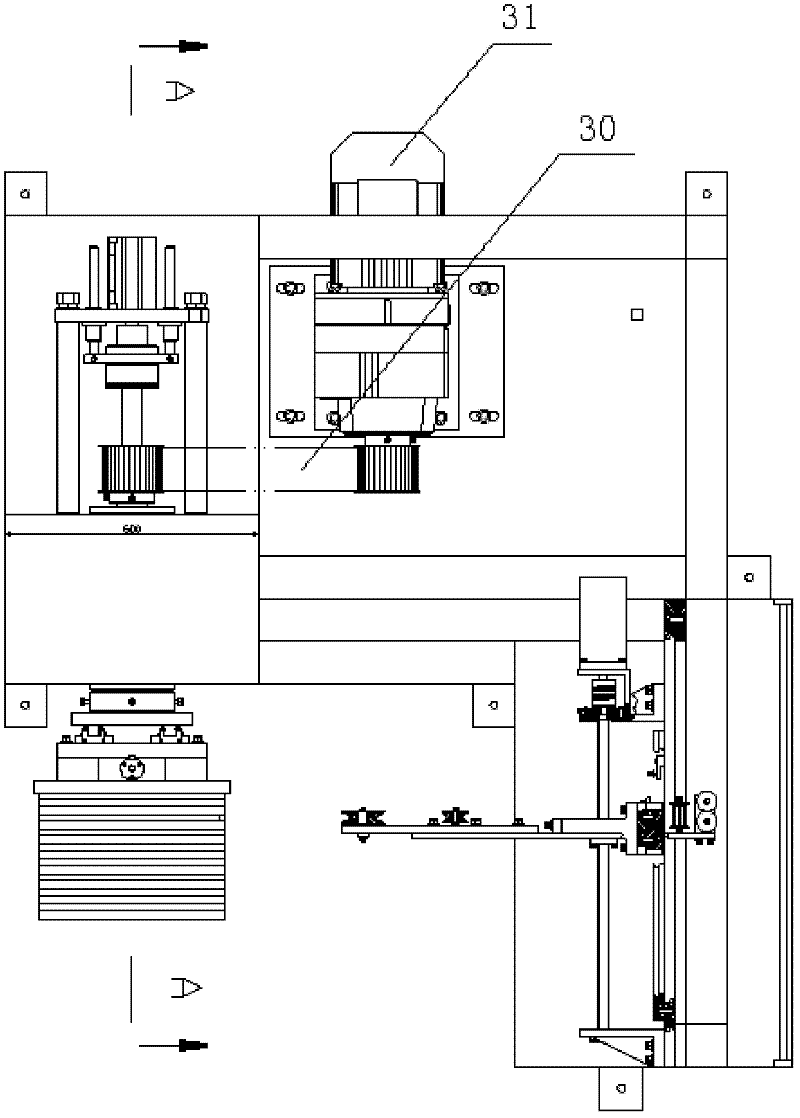

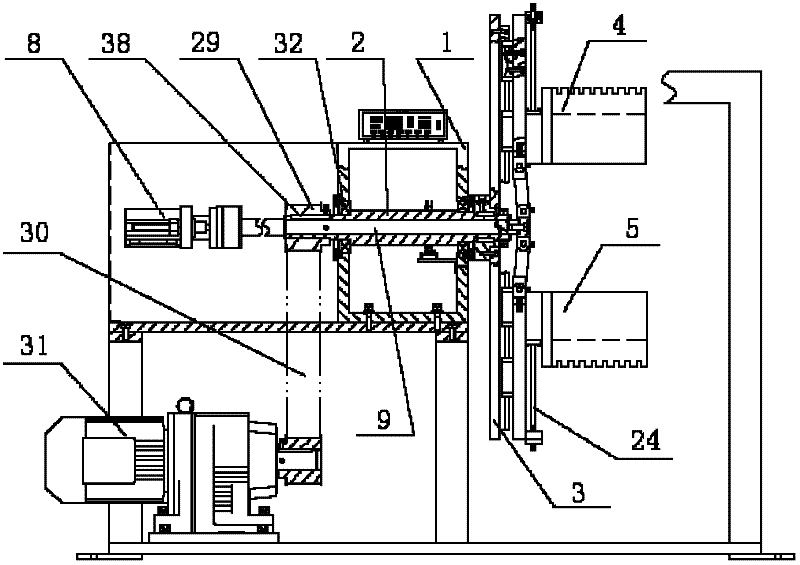

[0032] Embodiment one: see Figure 1-8As shown, a high-power three-phase stator coil winding machine includes a shaft box 1, a wire releasing mechanism 35, a wire hanging mechanism 36 and a winding mold mechanism. The shaft box 1 is provided with a rotating main shaft 2, and the winding The wire mold mechanism is connected with the rotating main shaft 2 through the turntable 3, and the winding mold mechanism includes an upper mold 4 and a lower mold 5, and the upper mold 4 and the lower mold 5 are arranged symmetrically with the center of the rotating main shaft 2, and the upper mold 4. The opposite side of the lower mold 5 is respectively provided with 8 winding slots 6, and the distance between the upper winding slots 6 of the upper mold 4 and the corresponding winding slots 6 of the lower mold 5 matches the diameter of the coil to be wound. Above-mentioned upper mold 4 is installed on an upper base 7, and described lower mold 5 is installed on the lower base 37, and upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com