Screw lamp holder torsion testing device and torque testing method thereof

A screw lamp holder and torque testing technology, which is used to measure the direction of torque/torsion force when tightening, can solve the problems of unsure torque value, potential safety hazards, and broken bulbs, etc., to achieve convenient operation, simple structure, and fast testing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

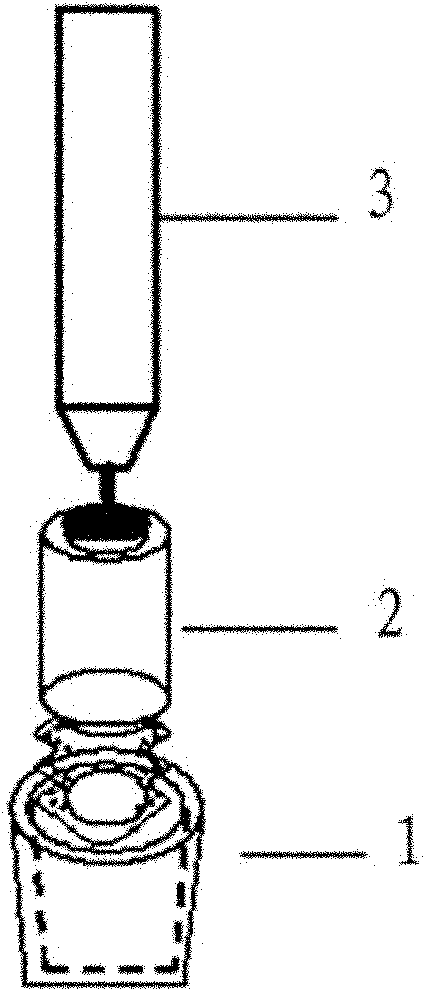

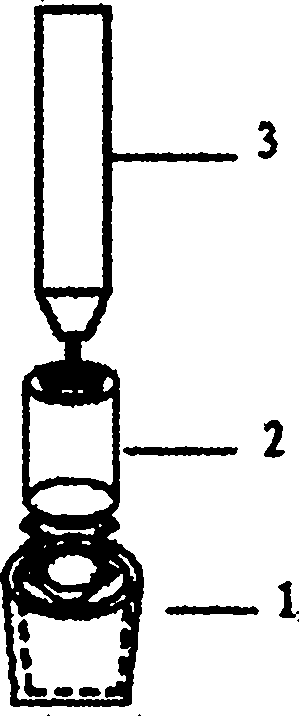

[0031] Screw lamp holder torsion testing device of the present invention, such as figure 1 and figure 2 As shown, it includes a fixed seat 1, a connecting piece 2 and an electric batch 3 with adjustable torque;

[0032] The fixing seat 1 is used to fix the screw lamp holder to be tested;

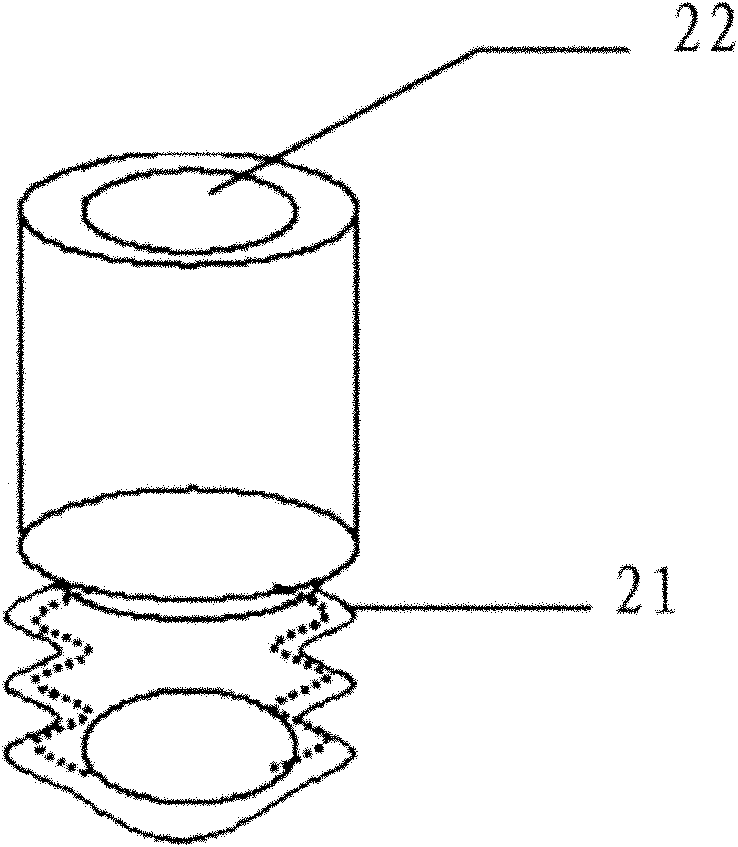

[0033] One end of the connecting piece 2 is provided with an external thread 21, and the external thread 21 is matched with the thread of the screw lamp holder to be tested; the other end of the connecting piece 2 is provided with a groove 22, and the adjustable torque Electric batch 3 can be embedded in the groove;

[0034] The torque-adjustable electric screwdriver 3, according to the set torque, screws the end of the connecting piece provided with the external thread into or out of the screw lamp holder to be tested.

[0035] An electric screwdriver, also known as an electric screwdriver, is an electric tool for tightening and loosening screws. Equipped with a mechanism for adjusting...

Embodiment 2

[0043] The screw lamp holder torsion testing method of the present invention comprises the following steps:

[0044] Step S01: fixing the screw lamp holder to be tested in the fixing seat;

[0045] Step S02: Set the torque of the electric batch with adjustable torque;

[0046] Step S03: Insert the electric screwdriver with adjustable torque into the groove of the connector;

[0047] Step S04: Put the connecting piece on the screw lamp holder to be tested;

[0048] Step S05: Start the electric batch with adjustable torque; screw the end of the connector with external thread into or out of the screw lamp holder to be tested according to the set torque;

[0049] Preferably, step S05 is executed multiple times to reach the number required by the mandatory national standard.

[0050] The screw lamp holder torque testing device and the screw lamp holder torque testing method of the present invention ensure that the screw lamp holder can withstand the influence of the torque gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com