Device for preventing off-shell phenomenon in product assembly

A technology for products and moving molds, applied in the field of devices to prevent the separation of product assembly shells, can solve problems such as poor shipments, product flatness not meeting requirements, and prone to warping and deformation, so as to improve production efficiency and ensure shipments. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

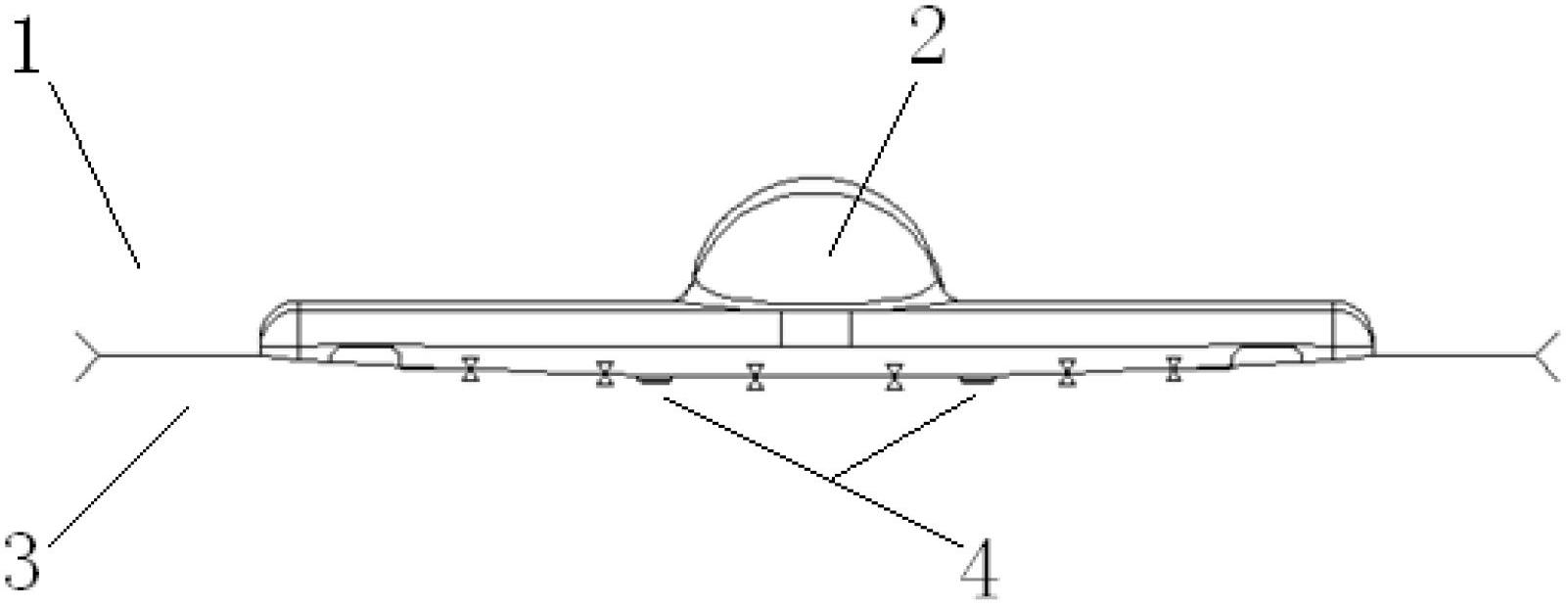

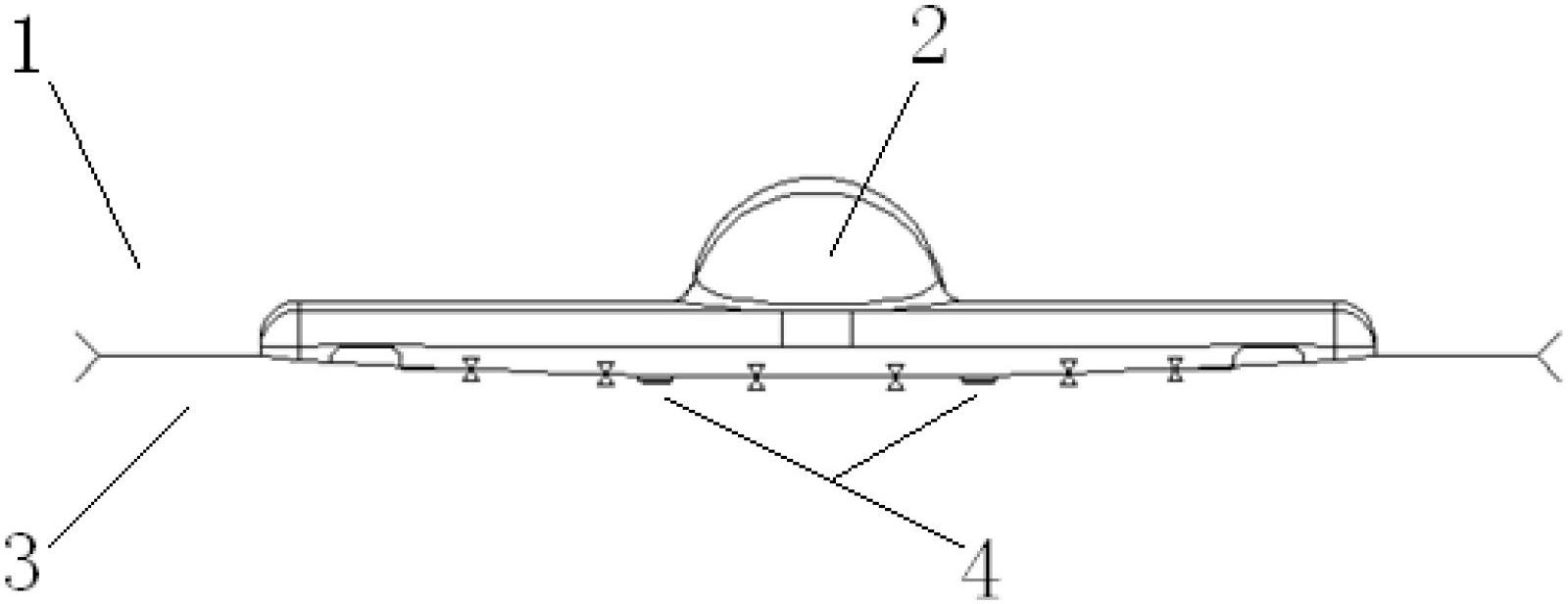

[0013] Such as figure 2 As shown, a device for preventing product assembly from separating includes a fixed mold 1, a product 2, a movable mold 3, and a set screw hole 4. The fixed mold 1 is installed and fixed on the movable mold 3, and the fixed mold 1 and the movable mold The parting surface between the molds 3 is an arc surface.

[0014] A product 2 is installed in the cavity between the fixed mold 1 and the movable mold 3 .

[0015] There are two symmetrical set screw holes 4 corresponding to the position of the product 2 in the moving mold 3 .

[0016] The new mold design uses a pre-deformation device, that is, the parting surface (PL) is designed to be arc-shaped, which is opposite to the warping deformation direction of product 2 and has the same arc. In this way, after product 2 is injection molded, the warping deformation will pull the parting surface (PL) from the arc shape to almost a horizontal plane. After modifying the mold device, the warping deformation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com