Three-in-one sealed flexible core setting fixture

A three-in-one, flexible technology, applied in the direction of manufacturing tools, molding machine parts, casting and molding equipment, etc., can solve the problems of uneven thickness of the workpiece, high labor intensity of core setting, and difficulty in user maintenance, etc., to achieve reduction The effect of inaccurate positioning, improving the range of use, and compensating for shape and position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

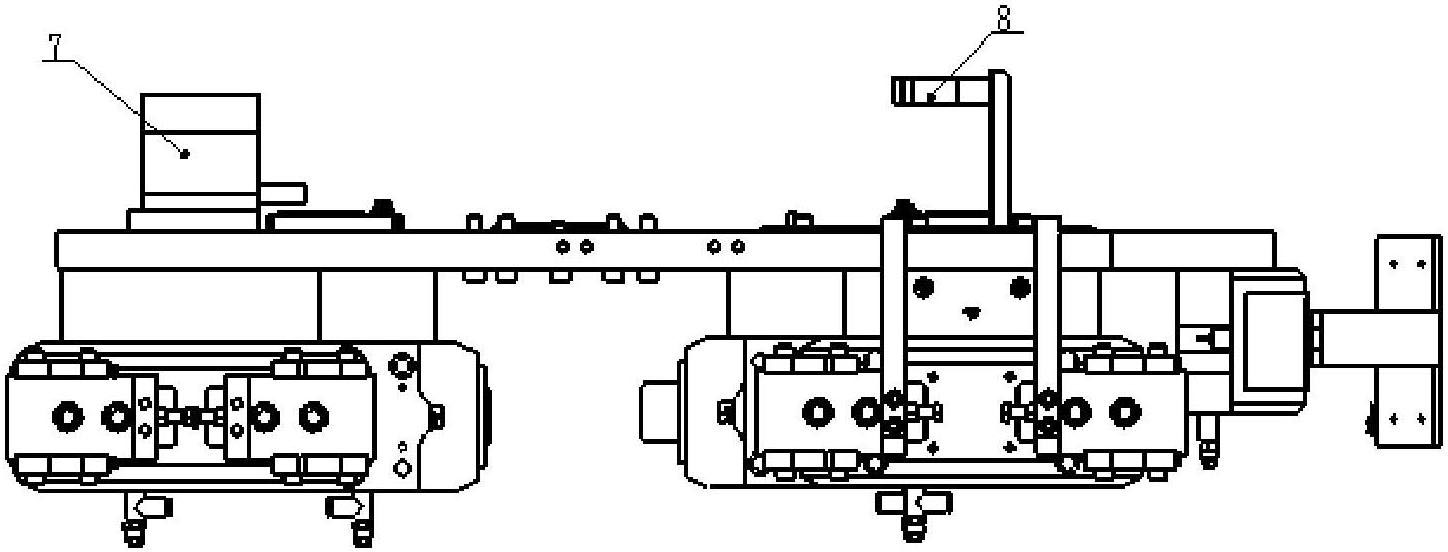

[0024] Such as figure 1 As shown: 5 sets of fixture devices are set on the main body mounting plate 1, which are fixed jaws 2 of the bolster sand core fixture mechanism, flexible jaw 3 of the bolster sand core fixture mechanism, square frame sand core fixture mechanism 4, and side frames Sand core fixture mechanism fixed jaw 5, side frame sand core fixture mechanism flexible jaw 6, air control unit 7, cable mounting frame 8.

[0025] Such as figure 2 , image 3 , Figure 4 Shown: bolster sand core fixture mechanism fixed jaw 2, bolster sand core fixture mechanism flexible jaw 3 is the jaw of bolster sand core, bolster sand core fixture mechanism fixed jaw 2, bolster sand core The air claws provided by the flexible jaws 3 of the fixture mechanism are all air claws I204. The two air grippers I 204 are respectively fixed to the mounting plate 205 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com