Ball mill

A bead mill and grinding chamber technology, applied in the field of grinding equipment, can solve the problems of low efficiency and small one-time grinding volume, and achieve the effect of high grinding efficiency and large grinding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

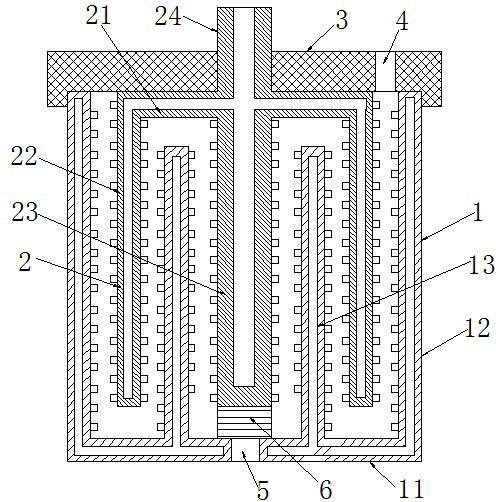

[0009] Embodiment: a bead mill, comprising a stator and a rotor, a grinding cavity is formed between the stator and the rotor, a plurality of grinding rods are arranged on the stator and the rotor, and a plurality of grinding rods are located in the grinding cavity, the stator It is a stator cylinder 1, and the stator cylinder is composed of a circular bottom surface 11, an outer ring cylinder wall 12 with a circular cross section and an inner cylinder wall 13 with a circular cross section. The wall is integrally formed upwards from the edge of the bottom surface, and the inner ring tube wall is integrally formed upwards from the middle of the bottom surface, and the bottom surface, the outer ring tube wall and the inner ring tube wall are coaxial, and the The rotor is a rotor cylinder 2, which consists of a circular top surface 21, a rotor cylinder wall 22 with a circular cross section, a central column 23 with a circular cross section and a connecting shaft with a circular cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com