Waterwheel-type aerator

A technology of water wheel aerator and main engine, which is applied in water aeration, water/sludge/sewage treatment, climate change adaptation, etc. It can solve the problems of reduced hole strength, high manufacturing cost, and expensive stainless steel. Achieve the effect of convenient assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

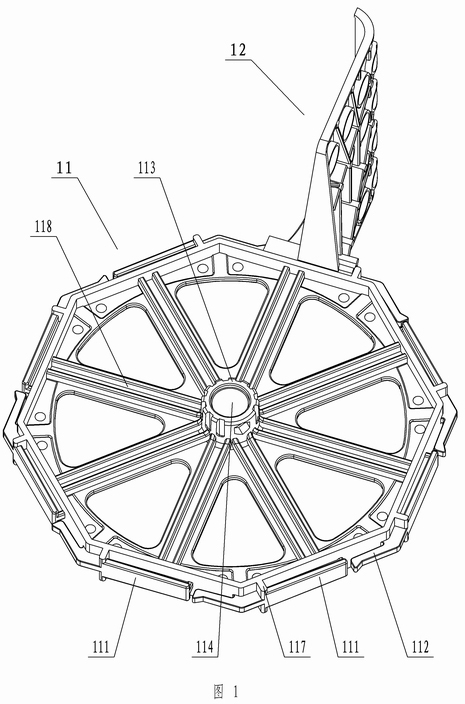

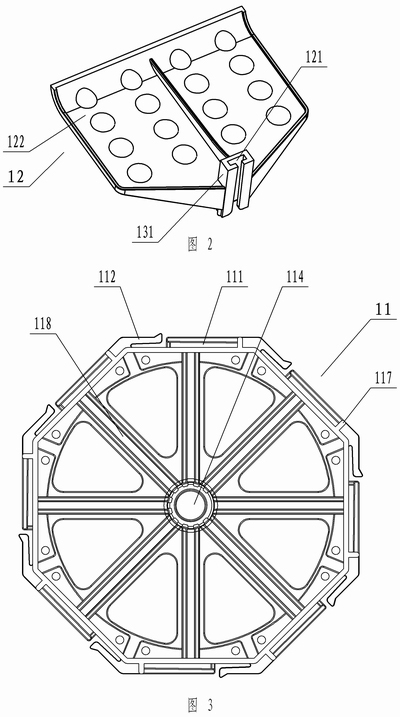

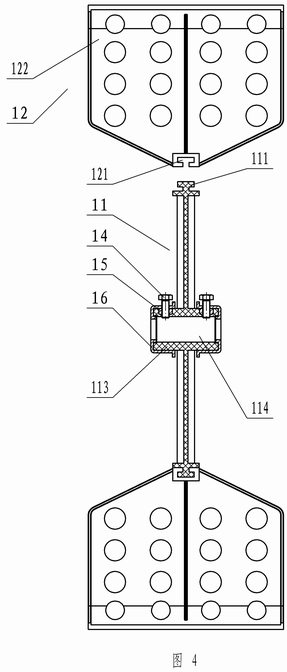

[0050] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-19 :

[0051]A waterwheel type aerator mainly includes impeller 1, floating body, main engine 3, transmission shaft 2, bearing seat 7, etc. The floating body is connected by thin-walled stainless steel square tube 6, and square tube hole 61 is formed on square tube 6 Two or more pontoons 5 are combined into floating bodies by bolts 63 through the square tube holes. There is a reinforcement plate 62 above the square tube hole 61. The two sides of the reinforcement plate are bent and wrapped around the square tube 6 sides. Bolt 63 is fixed in the groove position, and most of bolt is in the groove position of pontoon, and the side 53 width of pontoon can be reduced, and the packing volume of pontoon 5 is reduced, and groove 51 improves the load-bearing capacity of pontoon; The directly mounted motor 31 drives the horizontal output shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com