Electrified repairing method for 10kV line aerial conductors and insulating wire lifter

A technology of overhead wires and wire lifters, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reducing the reliability of line power supply, difficulty in lifting overhead wires, and reducing economic benefits, so as to improve economic and social benefits and improve power supply Reliability rate and electricity sales, and the effect of reducing social conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

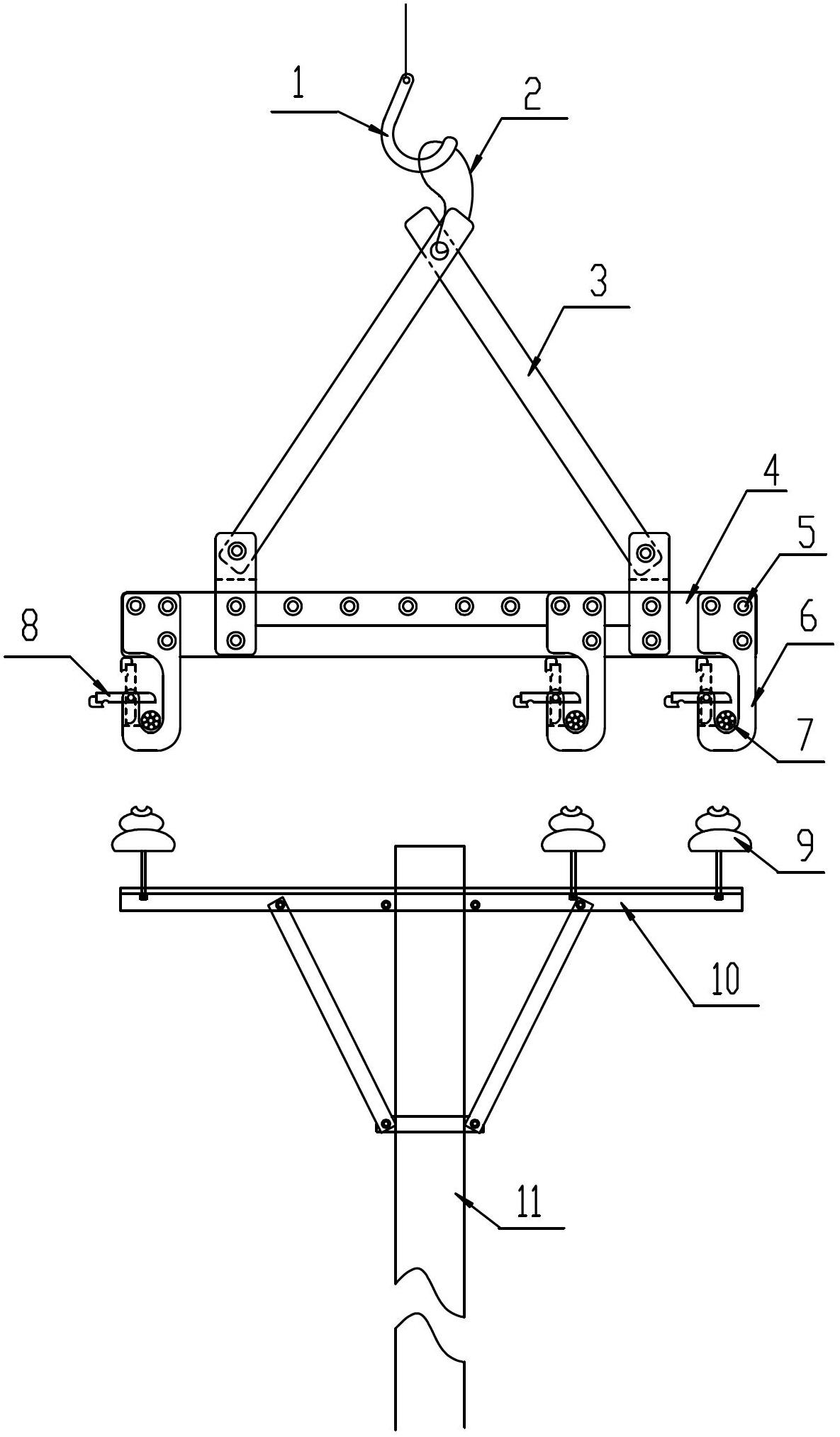

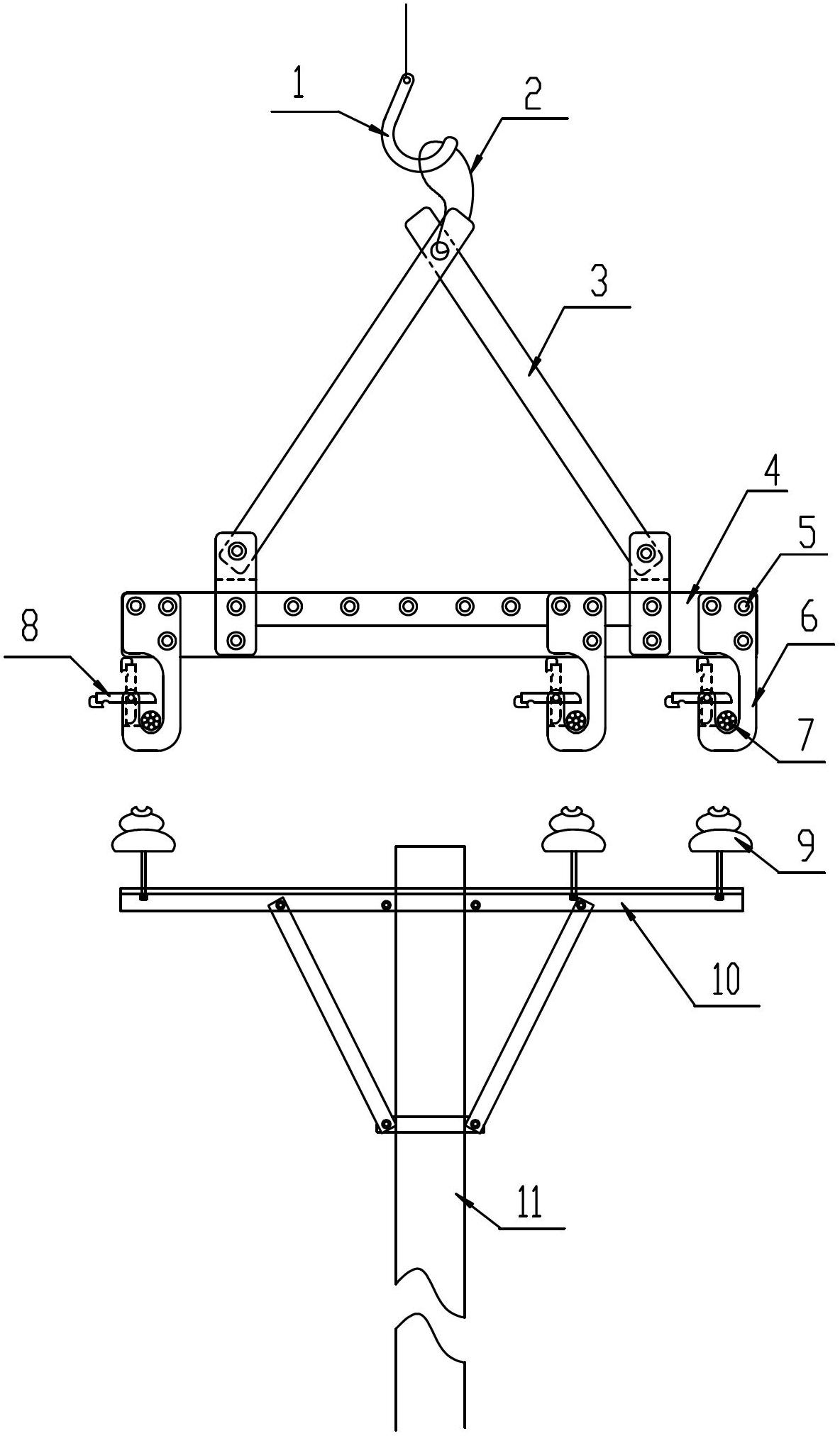

[0014] See figure 1 , is a schematic diagram of the application state structure of the embodiment of the insulating wire lifter of the present invention. The device includes an insulating cross arm 4, an insulating clip spring 8 and an insulating hanger 6. The positions of the insulating cross arm 4 corresponding to the three-phase overhead conductor 7 are passed through insulating bolts respectively. 5 is provided with three insulating hangers 6, and the opening of the insulating hangers 6 is provided with an insulating clip 8. Two insulating hanging plates 3 are arranged on the insulating cross arm 4, and one end of the insulating hanging plate 3 is hinged with the insulating cross arm 4, and the other end of the insulating hanging plate 3 is provided with a hanging hole, which is convenient for lifting by a crane.

[0015] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com