Sliding mounting method for large-sized transformer

A technology of transformer and sliding method, which is applied in the direction of transformer/reactor installation/support/suspension, switchgear, electrical components, etc., and can solve the problems of large-scale hoisting equipment and many construction workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

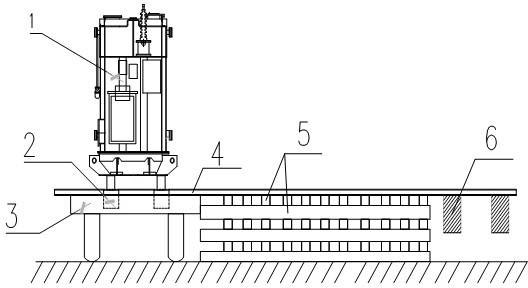

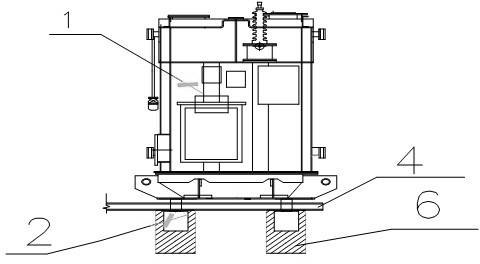

[0018] Such as figure 1 , 2 , Shown in 3, 4, large-scale transformer sliding method of the present invention comprises oil pumping station, hydraulic jack, heavy object on-rail type pushing machine, track, sleeper, transformer. After the transformer is transported in place, sleepers are laid in advance, the transformer is jacked up, then inserted into the rail, and the transformer is pushed to the installation position in the center of the foundation by using the on-rail pusher.

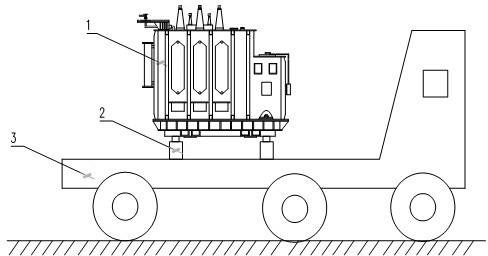

[0019] From figure 1 It can be seen that when the transformer 1 is loaded and transported, it is necessary to ensure that there is a certain reserved space at the bottom of the transformer to facilitate the placement of four hydraulic jacks 2 for lifting work, and the parking position of the transport vehicle 3 must be determined to ensure that the transformer can slide horizontally direction.

[0020] During the jacking process, the four hydraulic jacks 2 must be synchronized, the transformer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com