Method for processing material performance of composite material at wet fitting joint

A composite material and material performance technology, which is applied in the field of processing the material properties of composite wet assembly joints to achieve the effect of high engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

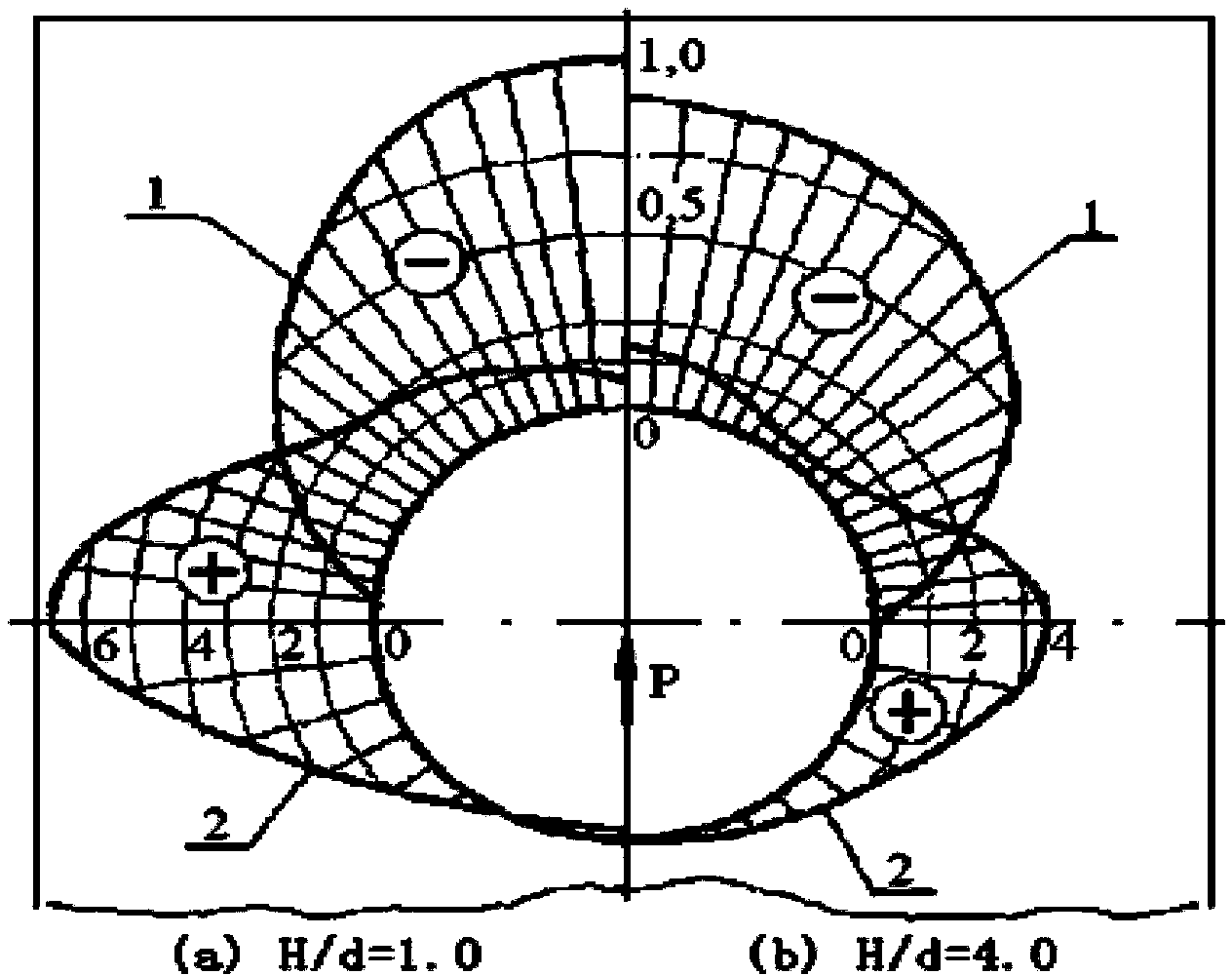

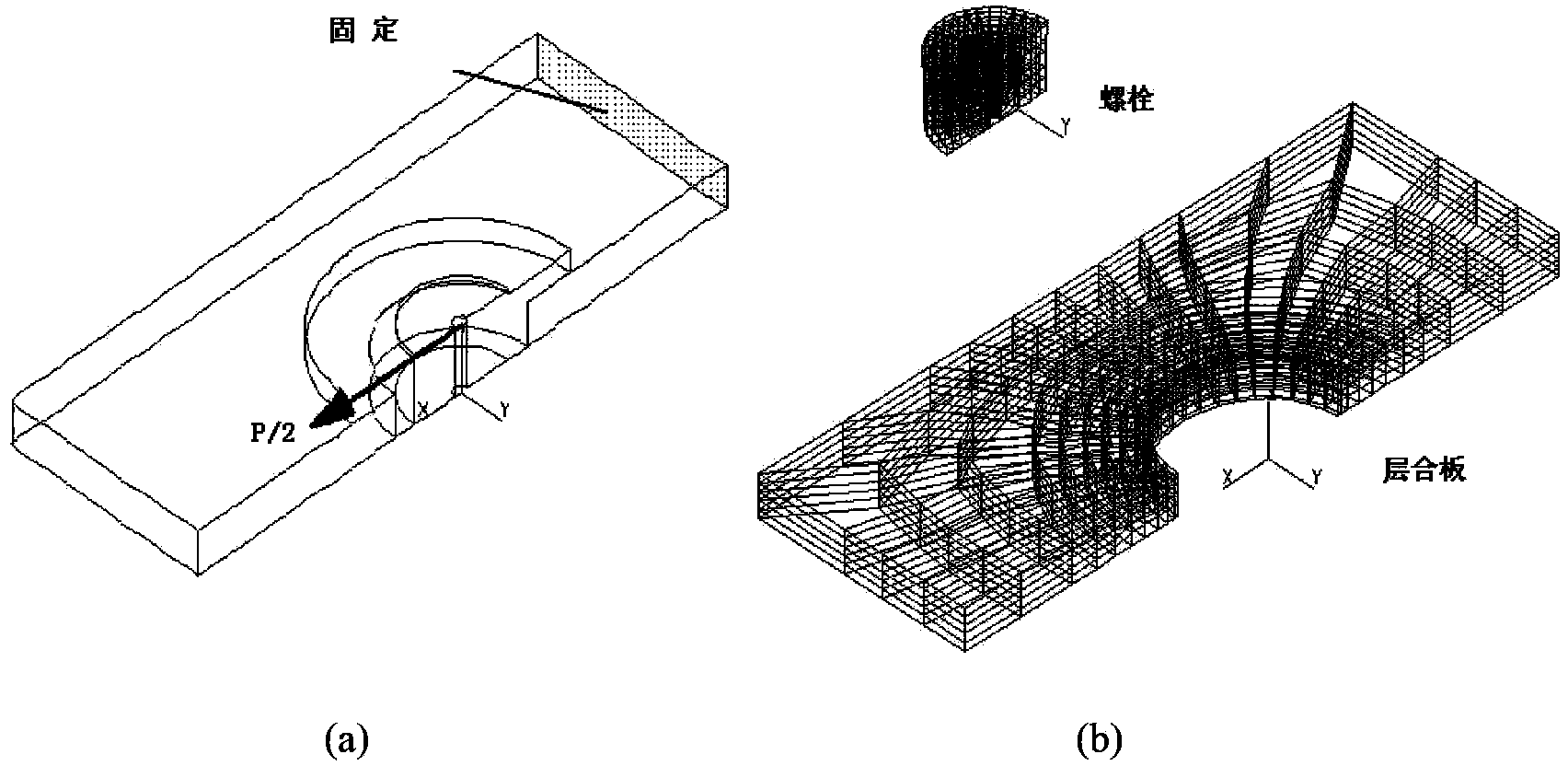

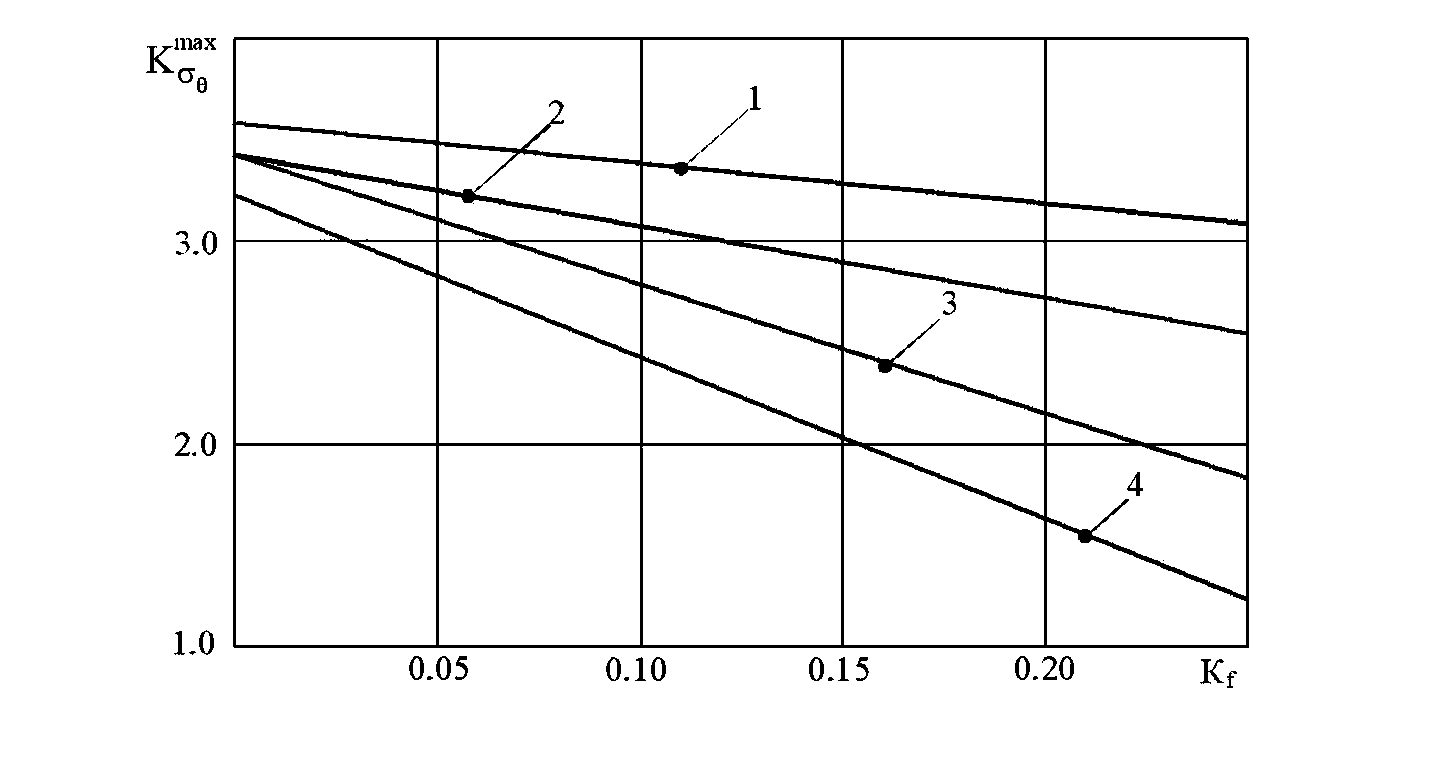

[0035] The invention provides a stress analysis modeling method for the edge of a mechanical connection bolt hole, adopts a three-dimensional finite element modeling method, and determines a reasonable element size to ensure the rationality of the analysis result.

[0036] (1) Geometry size of hole edge analysis model

[0037] Based on the diameter d of the hole, in the load direction (connector load), half of the model length L must be at least 4d, that is, L / 2≥4d, and in the vertical load direction, half of the model width must be at least 2.5d , Ie W / 2≥2.5d, the model is constrained at one end in the load direction.

[0038] (2) Element type and size

[0039] The element is hexahedral element (HEX8). In the transition area or fillet area, a small amount of pentahedral element (WEDGE6) can be used as required. In the hexahedral element, the aspect ratio or aspect ratio or aspect ratio is preferably 1 :1, the maximum ratio should not exceed 10:1.

[0040] (3) Processing method of thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com