Energy-saving baking oven for acoustic component of passenger cars

An acoustic component and energy-saving technology, which is applied in the field of energy-saving ovens for passenger car acoustic components, can solve the problems of inability to ensure high-precision positioning of heating sheet materials, invalid actions, waste of space and heating energy, and inconsistency in the actual area of the heating area, etc. problem, to achieve the effect of simple structure, lower production cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

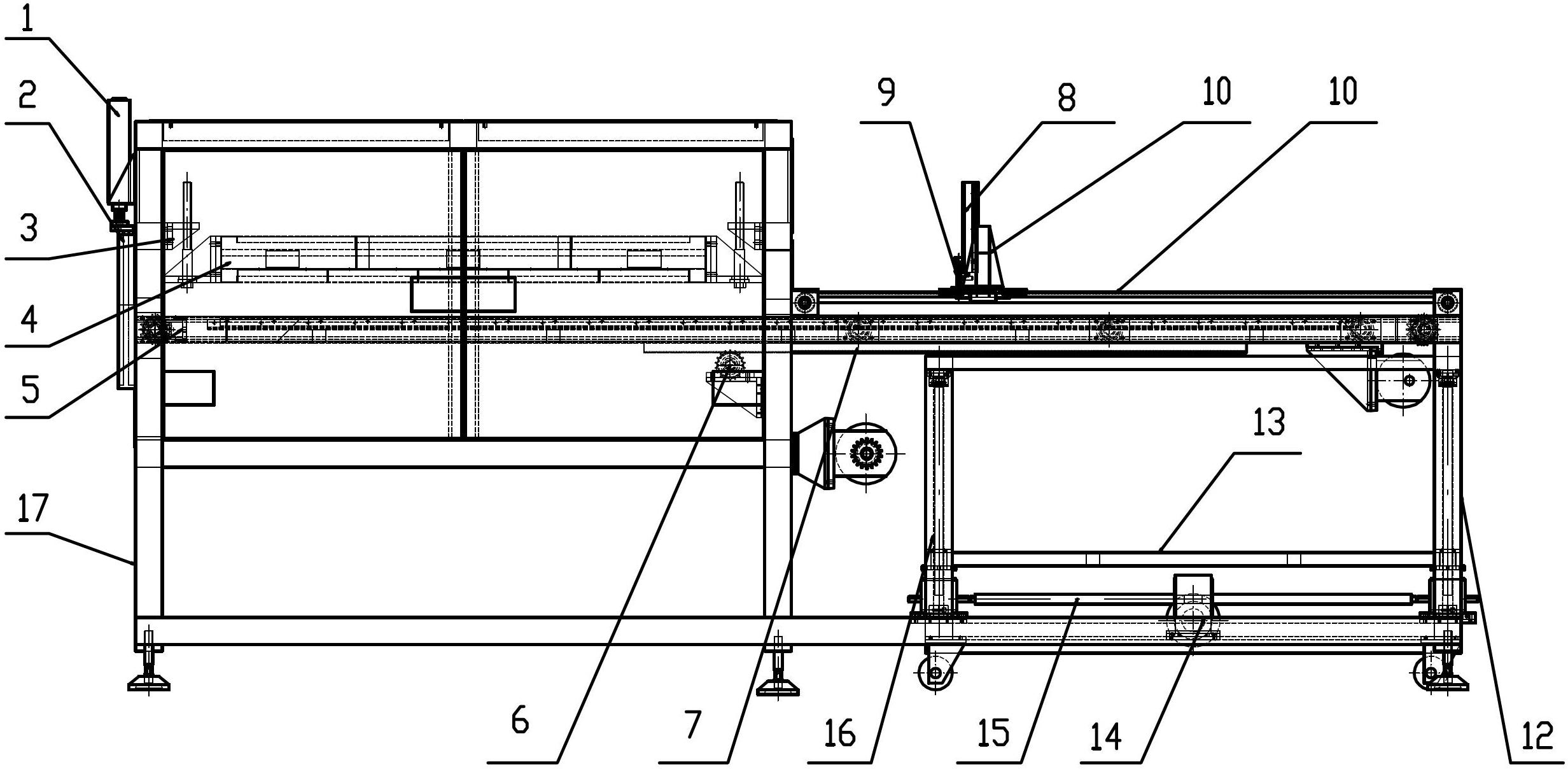

[0009] As shown in the figure: the passenger car acoustic component energy-saving oven has a baking chamber installed on the frame 17, a heating plate support seat 3 is fixed on the inner wall of the baking chamber, and a heating plate support seat 3 is fixed on the heating plate support seat 3. Plate 4, a movable door lift cylinder 1 is installed on the outer wall of the baking chamber at the discharge port position, and a movable door 2 is installed on the piston rod of the movable door lift cylinder 1; a drive gear 6 is installed on the frame 17 for rotation, A rack 7 is slidably installed on the frame 17, and the driving gear 6 meshes with the rack 7. On the rack 7, a circulating network chain mounting frame is fixed, and a driving sprocket and a driving sprocket are installed in rotation at both ends of the circulating network chain mounting frame. Passive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com