Belt adjuster for spin dryer

A technology of adjuster and drying machine, applied in belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of cost, labor, inconvenience, etc., and achieve the effect of easy production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

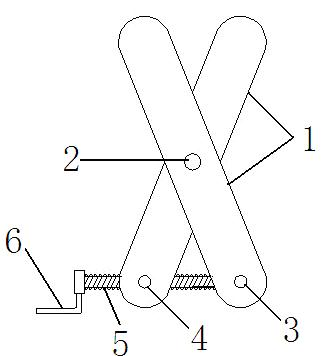

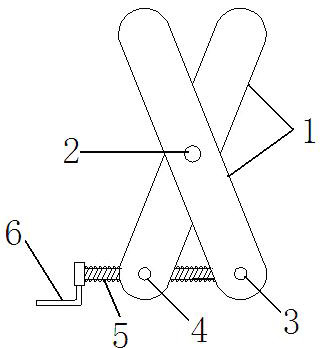

[0008] Such as figure 1 As shown, the present invention includes a screw rod 1 , a locking screw 2 , a bracket screw 3 , a screw 4 , a spring 5 and an adjustment handle 6 . The screw rods 1 are crossed into an X shape, and the middle position of the screw rod 1 is provided with a locking screw 2; the adjustment handle 6 is connected with the lower end of the screw rod 1 through the bracket screw 3 and the screw 4, and the adjustment handle 6 is provided with a spring 5 .

[0009] When the locking screw is loose, use the X-shaped screw adjuster to quickly adjust to the appropriate tightness, and then lock the bracket screw and the original adjusting screw to fix the position. Adjust the belt tightness at one time and ensure that the two axes are parallel, which improves the work efficiency.

[0010] The above-mentioned embodiments are not limitations to the present invention, and the present invention is not limited to the above-mentioned examples, and changes, modifications, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com