Brake horseshoe

A technology of brake shoes and brake shoes, which is applied in the direction of brake parts, brake types, mechanical equipment, etc., can solve the problems of easy sliding and dislocation of friction plates, alarm of friction plate wear, and misplacement of friction plates, etc., to protect personal safety and property safety, manufacturing cost reduction, and the effect of simplification of fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

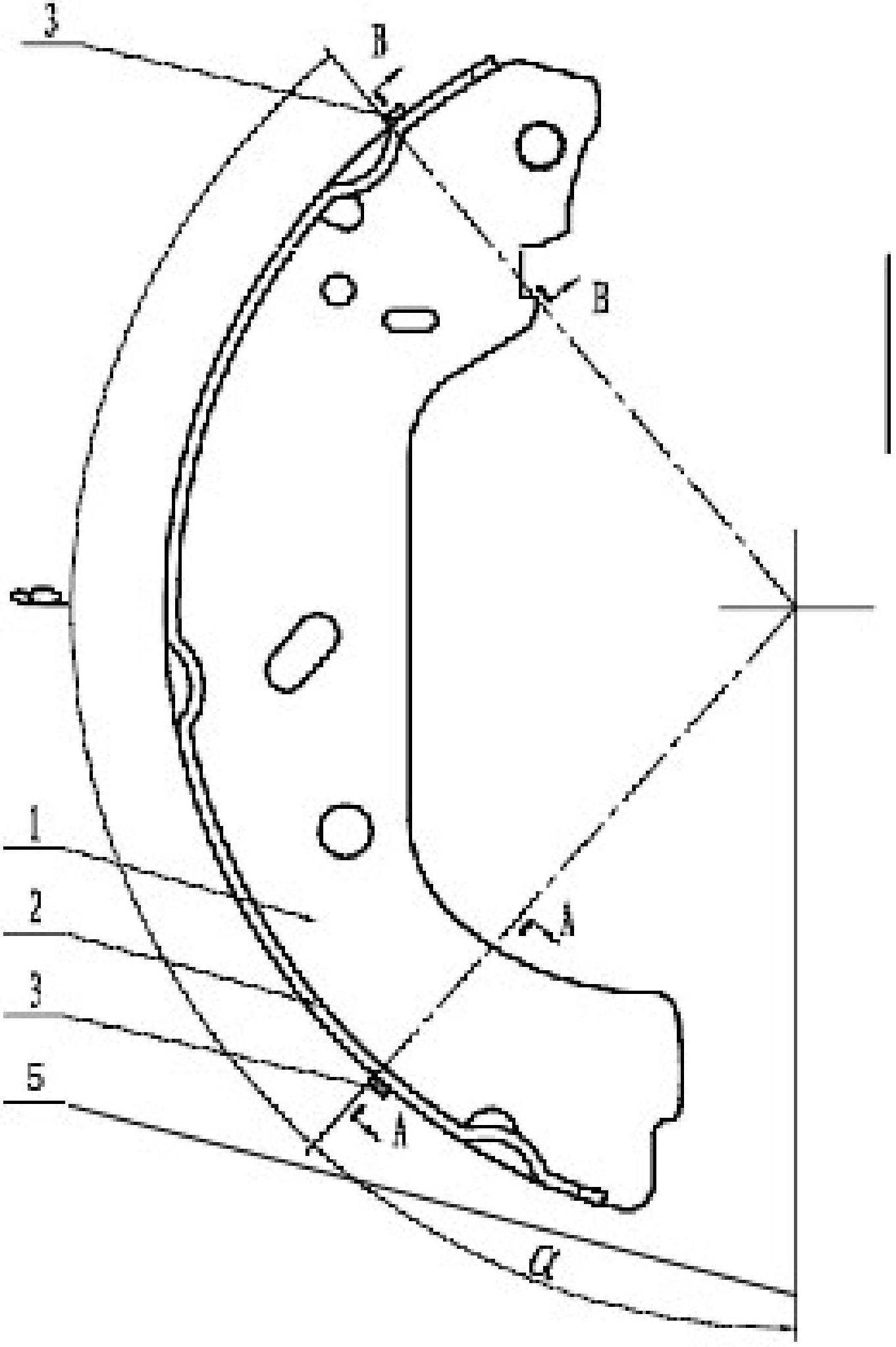

[0029] like figure 1 , figure 2 As shown, a brake shoe includes a web 1 and a wing 2, the wing (2) is connected with the arc-shaped outer periphery of the web 1, and the wing 2 is arched; it also includes a positioning alarm boss 3 , the positioning alarm boss 3 is located on the contact surface between the wing plate 2 and the friction plate 4 .

[0030] The positioning alarm boss 3 is stamped from the wing plate 2 without additional process and does not increase the manufacturing cost.

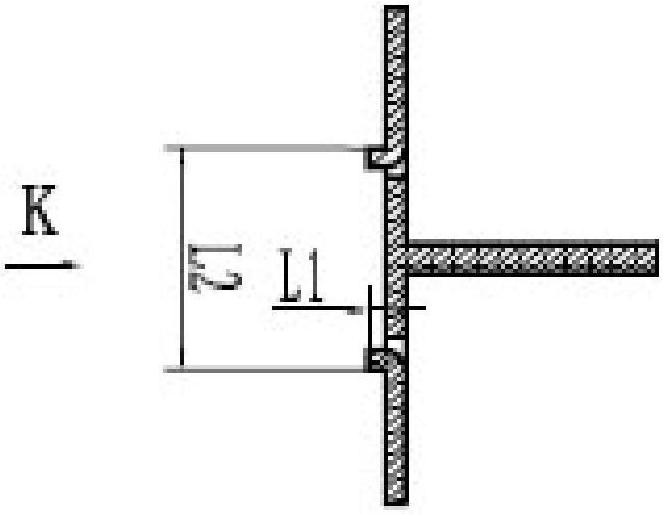

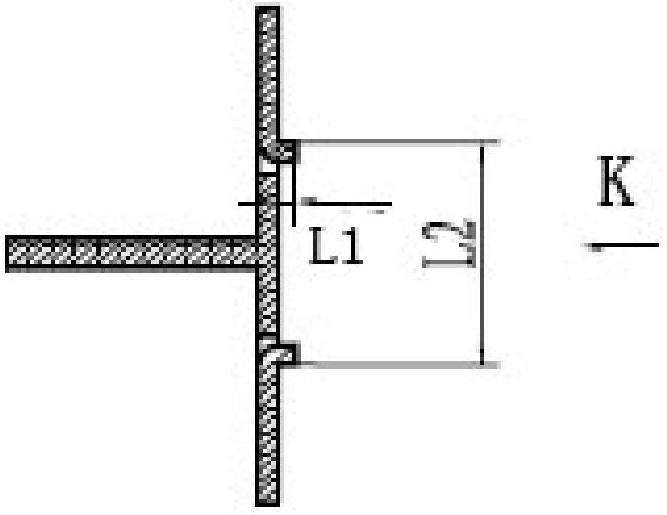

[0031] like Figure 4 As shown, the height of the positioning alarm boss 3 is L1 is 1 mm, and the height of the positioning alarm boss 3 is the limit thickness of the allowable wear of the friction plate 4 required by the design.

[0032] There are four positioning alarm bosses 3, two of which form a group, and one group is located on the starting angle α of the brake shoe (that is, the angle to the center line 5 is α), where as shown in the figure, α =30°; the other group is located at...

Embodiment 2

[0036] A brake shoe, comprising a web 1 and a wing 2, the wing 2 is connected to the arc-shaped outer periphery of the web 1, the wing 2 is arched; it also includes a positioning alarm boss 3, the positioning alarm The boss 3 is located on the contact surface between the wing plate 2 and the friction plate 4 .

[0037] The positioning alarm boss 3 is stamped from the wing plate 2 without additional process and does not increase the manufacturing cost.

[0038] The height of the positioning alarm boss 3 is 0.5 mm, and the height of the positioning alarm boss 3 is the limit thickness of the allowable wear of the friction plate 4 required by the design.

[0039] The positioning alarm boss 3 surrounds the friction plate 4 to form a continuous strip-shaped protrusion. The friction plate 4 is completely limited in the space enclosed by the protrusion.

[0040] When the friction plate 4 is bonded with the brake shoe, just align one end of the friction plate 4 with the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com