Vertical axis wind generation device

A wind power generation device, vertical axis technology, applied in wind turbines, wind turbine combinations, wind turbines at right angles to the wind direction, etc., can solve the problem that the width of the blades cannot be made very wide, the starting wind speed is required to be large, and the utilization rate of wind energy is low. and other problems to achieve the effect of improving wind energy utilization, improving wind resistance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

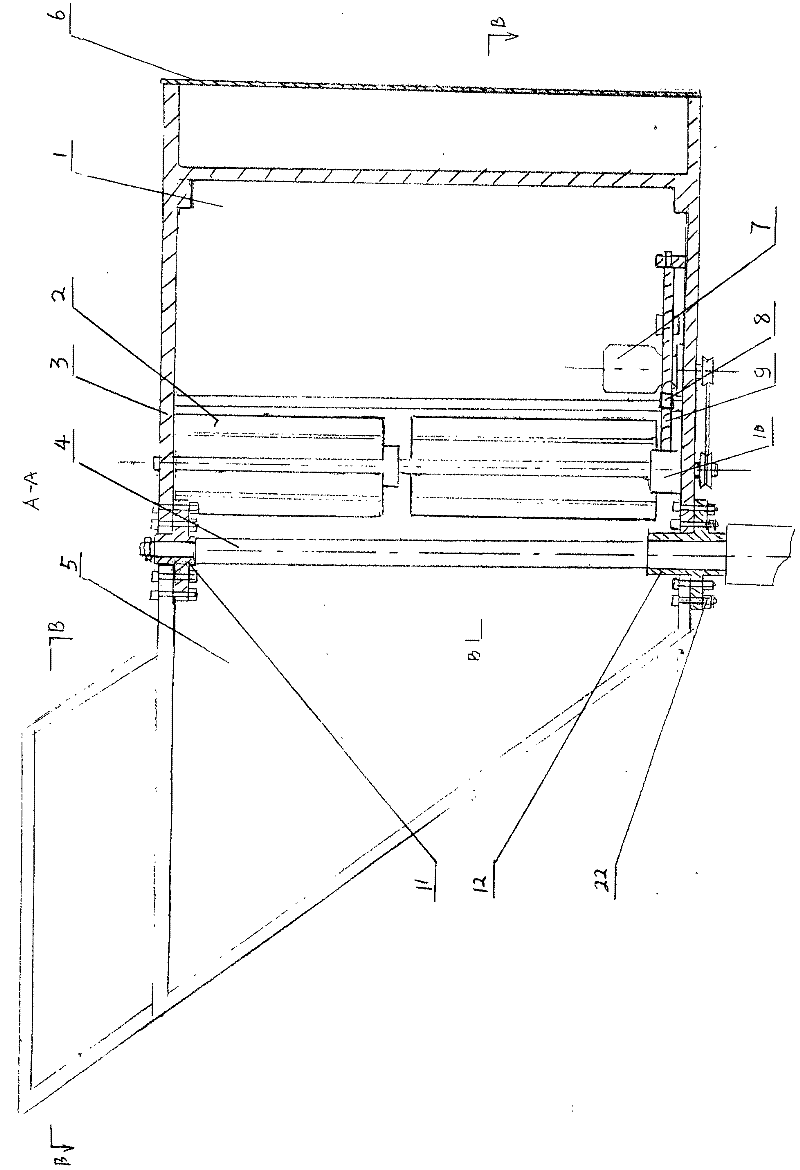

[0023] figure 1 It is the front structural diagram of the present invention;

[0024] The fixed vertical shaft part 4 in the figure is the supporting part of the device, and its lower end is fixed on the earth or other supports, and the upper rotating shaft sleeve 11 and the lower rotating shaft sleeve 12 are connected on the fixed vertical shaft part 4, and can rotate around the center of the vertical shaft 4 , the rear upper and lower ends of the front bracket part 3, the front upper and lower ends of the rear bracket empennage part 5, are respectively fixed on the upper and lower rotating bushings 11 and 12 by bolts 22. The front support part 3, the fixed vertical shaft part 4, the rear support tail part 5, and the vertical central plane of the splitter plate 6 are located in the same vertical plane. When the wind blows from any direction, due to the effect of the rear support tail part 5, the device rotates around the center of the fixed vertical shaft part 4, and keeps t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com