Air intake manifold with auxiliary resonant cavity

A technology of intake manifold and resonant cavity, which is applied in combustion air/combustion-air treatment, internal combustion piston engine, engine components, etc. The effect of short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

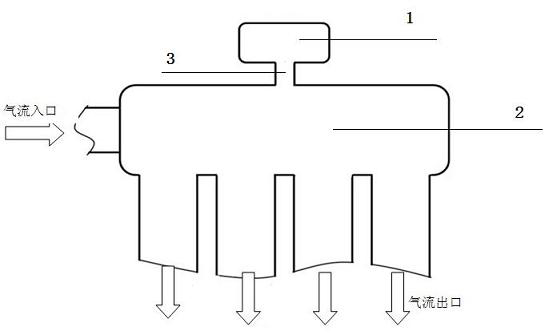

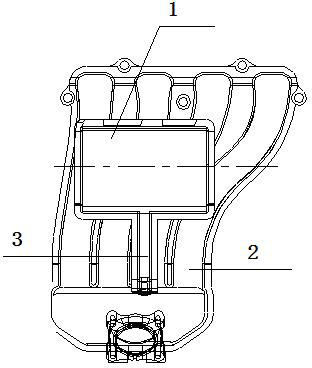

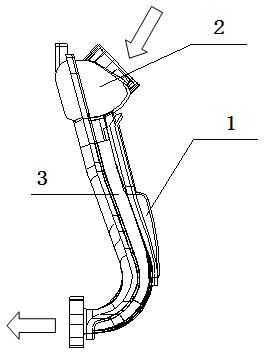

[0019] Combine below Figure 1 to Figure 4 , the present invention is further described:

[0020] Such as figure 1 As shown, a secondary resonant cavity intake manifold is provided with a main resonant cavity 1 and a secondary resonant cavity 2 on the intake manifold. The primary resonant cavity 1 has an airflow inlet and an airflow outlet. Cavity 2 is connected. The sub-resonant chamber 2 is only connected to the main resonant chamber 1, so within a certain speed range of the engine, the resonance energy will be increased and the charging efficiency will be improved, but the charging efficiency at other speeds will not be affected.

[0021] Such as figure 2 with image 3 As shown, changing the volume of the sub-resonator, the length and diameter of the connecting channel between the sub-resonator and the main resonator according to the performance requirements of a certain speed of the engine does not require a large-scale change in the design of the intake manifold to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com