Driving and connecting device for rotary drilling rig power head pile casing

A technology for driving connection and rotary drilling rigs, which is applied in the direction of rotary drilling rigs, rotary drilling, drilling equipment, etc., which can solve the problems of inconvenient installation of equipment and increase of equipment costs, and achieve simple structure, convenient assembly and disassembly, and avoid inconvenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

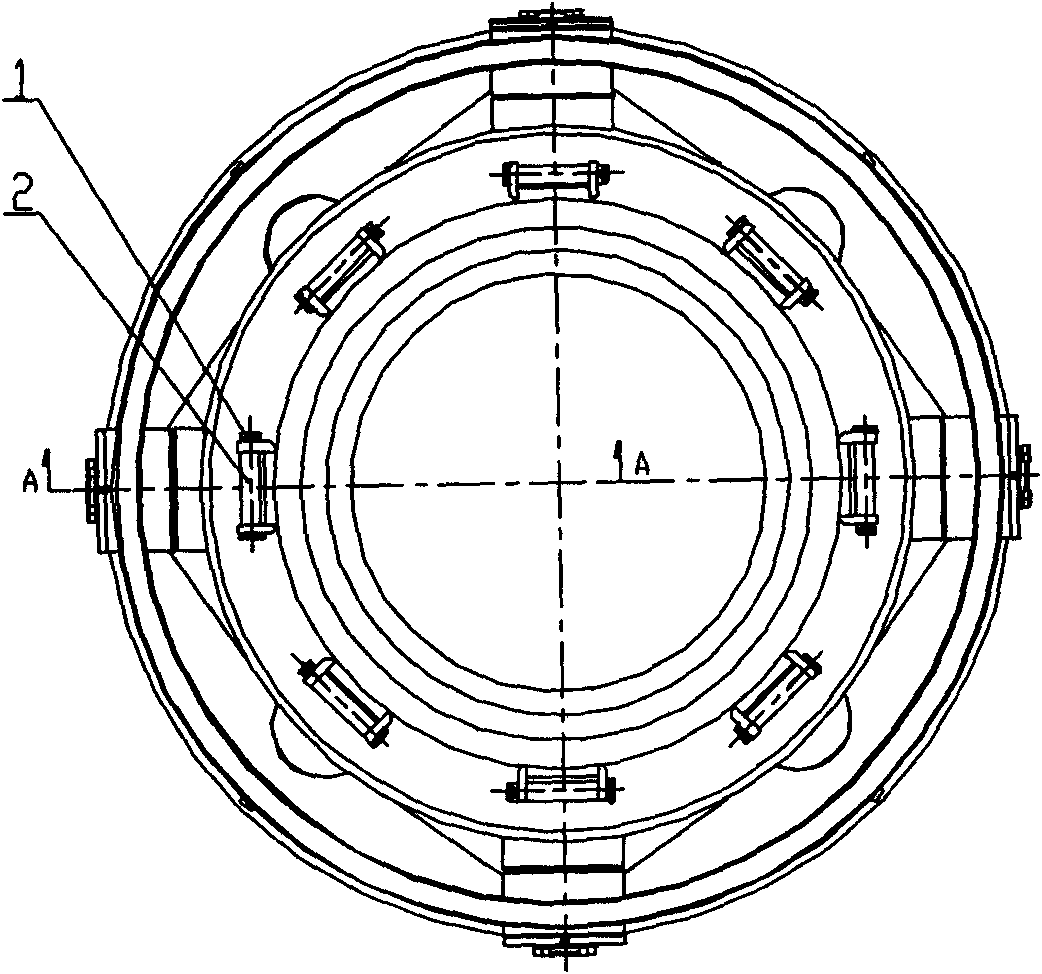

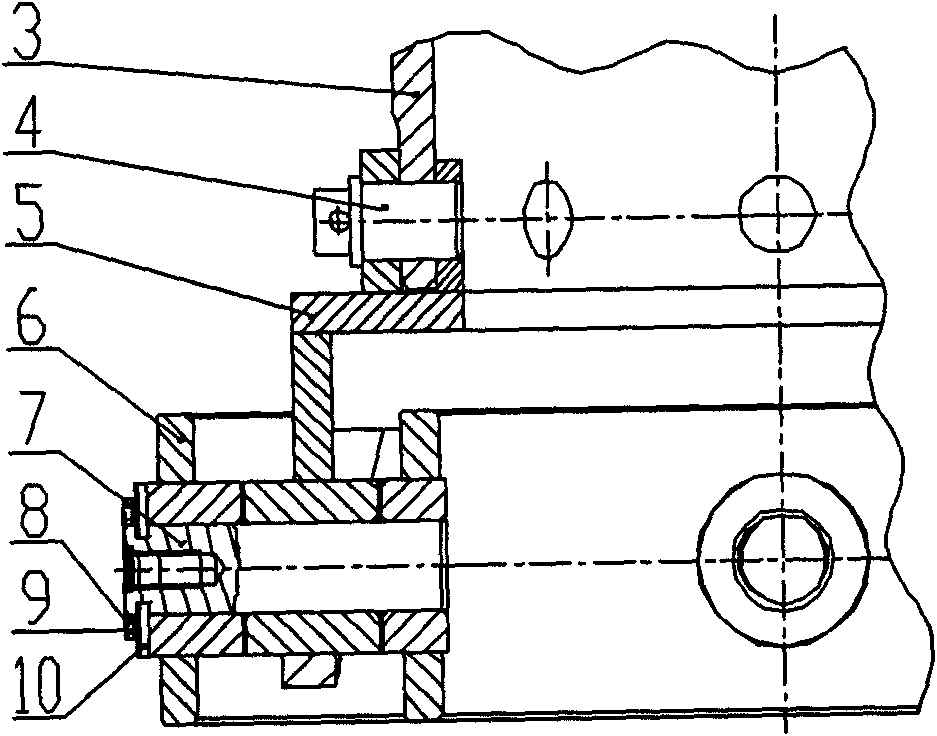

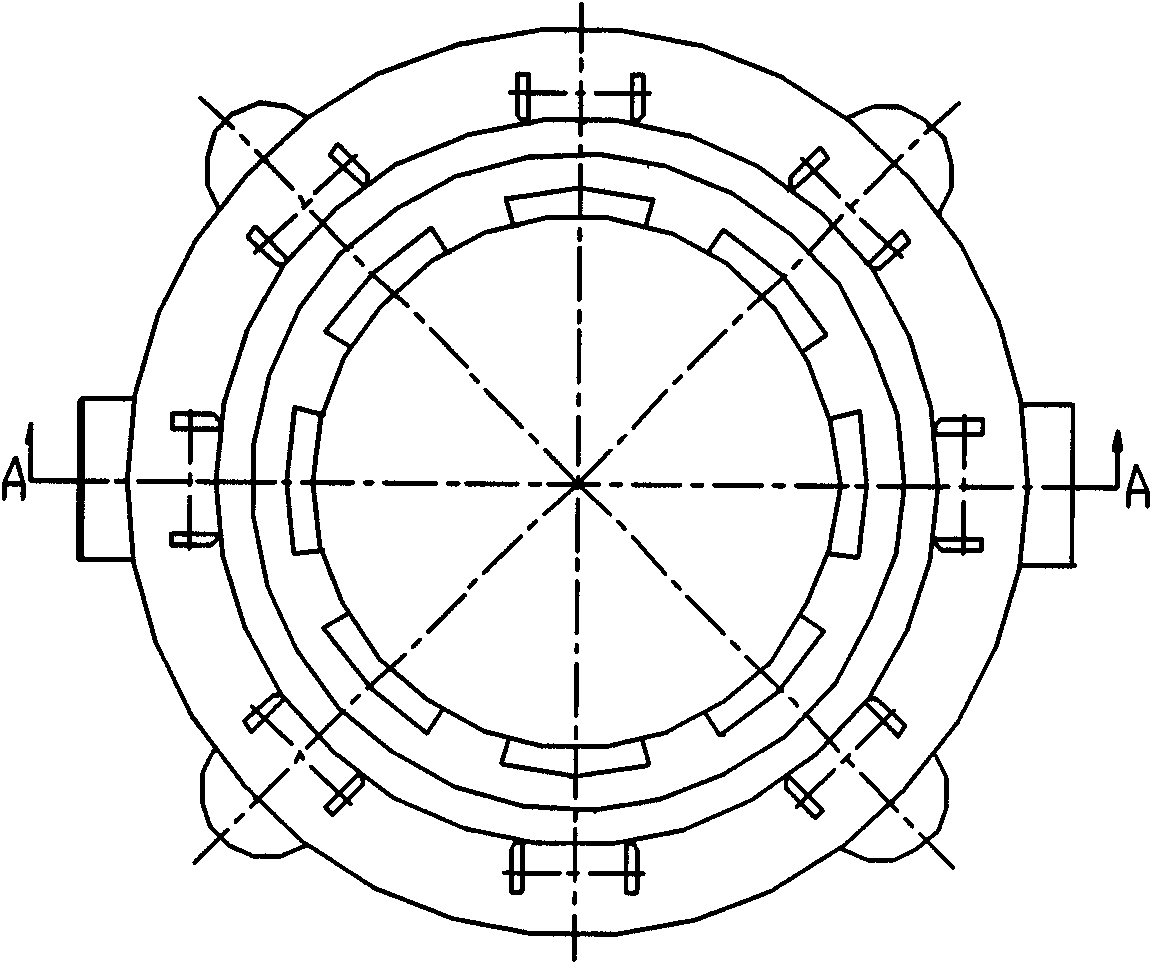

[0013] First, place the lower end of the power head connecting shaft (3) in the groove at the upper end of the connecting body (5), and connect and fix it through the pin shaft (4), stop pin (2) and cotter pin (1), so that the power head connecting shaft ( 3) It is reliably connected with the connecting body (5). Then connect the lower end of the connecting body (5) and the casing driver (6) through the pin shaft (7), install the baffle plate (10), the washer (9) and the bolt (8) to fix the pin shaft (7) axially, and realize Connection of connector and casing driver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com