Back hanging piece for installing decorative inorganic tetrafluoromethane veneer and construction method of back hanging piece

An inorganic, veneer technology, applied in the direction of covering/lining, construction, building construction, etc., can solve the problems of plate falling off, limiting the scope of use, and not being able to take it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

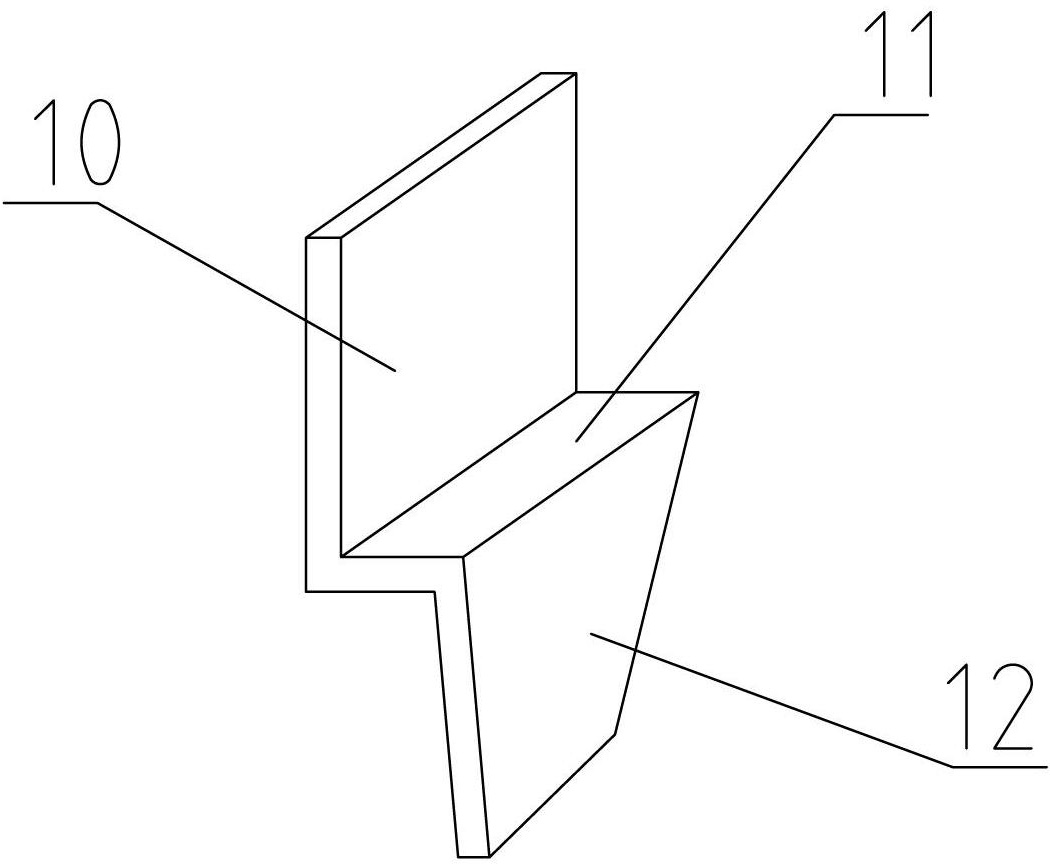

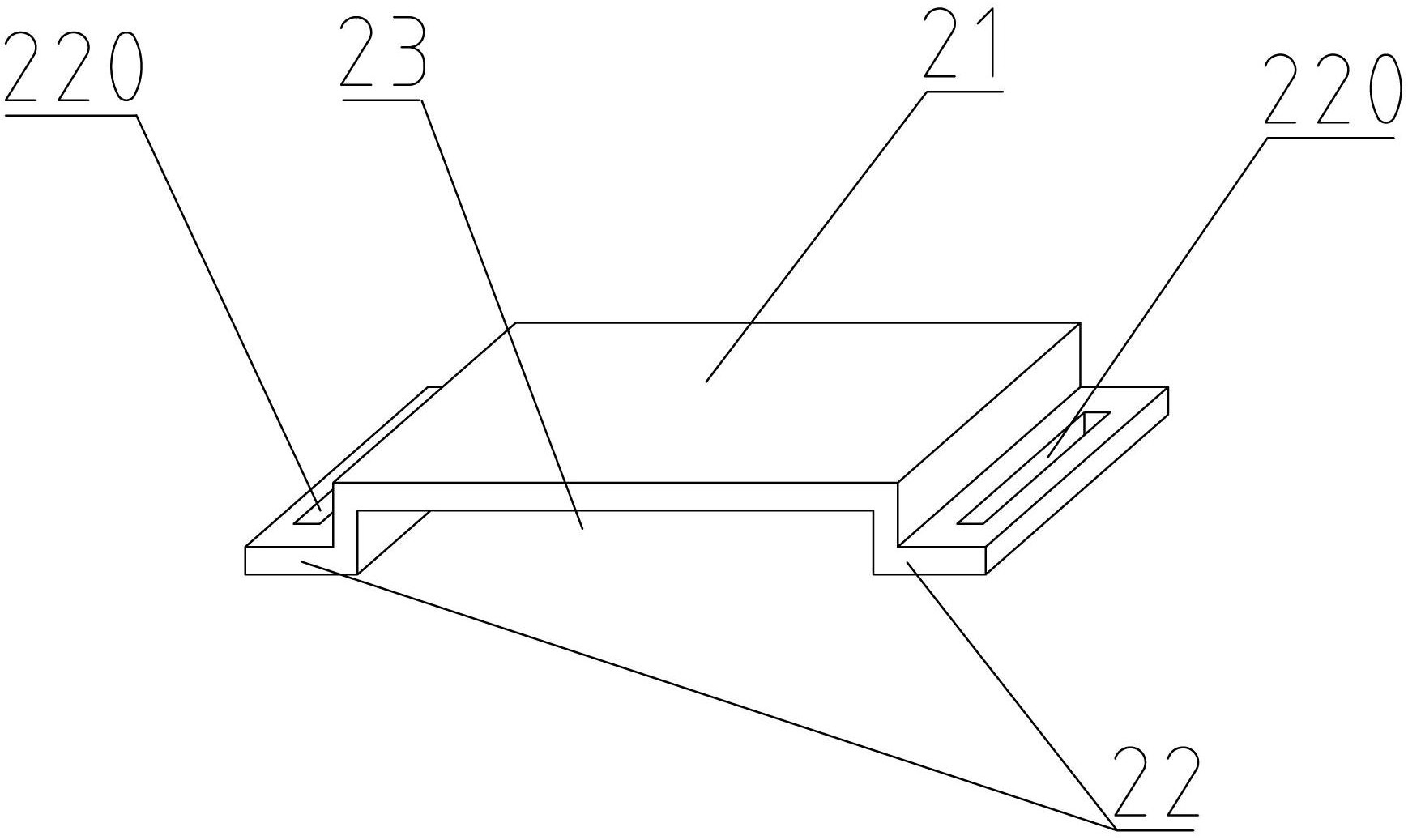

[0039] The structure of the back hanger installed on the fluorocarbon decorative inorganic veneer described in the first embodiment

[0040] The back hanger installed on the fluorocarbon decorative inorganic veneer of the present invention includes a plug-in and a positioning part used in conjunction with each other. The plug-in is fixed on the back of the fluorocarbon decorative inorganic veneer, and the positioning part is fixed on the wall, such as figure 1 As shown, the insert is an integral metal piece, which is divided into three sections, namely, the fixing part 10 that is close to the fluorocarbon decorative inorganic veneer, the insertion part 12 that cooperates with the positioning part, and the part between the fixing part 10 and the insertion part 12. The connection part 11 is connected end to end between the three sections and the connection part 11 is respectively perpendicular to the fixed part 10 and the insertion part 12, and the fixed part 10 and the insertion...

Embodiment 2

[0043] The construction process of the back hanger installed on the fluorocarbon decorative inorganic veneer described in the second embodiment

[0044] The construction and use method of the back hanger described in the application of the present invention comprises the following steps:

[0045] 1. Base surface cleaning: remove sundries and oil stains on the board surface and wall surface of the fluorocarbon decorative inorganic veneer;

[0046] 2. Flatness inspection: It is required that the flatness deviation of 2 meters should not be greater than 2 mm when checking with a ruler. If this requirement cannot be met, leveling treatment should be carried out, and the empty drum on the wall should be removed and refilled;

[0047] 3. Design and confirm the grid plan, mark the position of the plate and the position of the positioning part of the back pendant on the wall according to the grid plan (for the distribution position, see Figure 5 );

[0048] 4. Install horizontal and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com