U-shaped aqueduct simulation testing device and method

A test device and aqueduct technology, which is applied to hydraulic models and other directions, can solve the problems that the combined steel mold in the test section can only be used once and be scrapped, takes a lot of time, and wastes a lot of time, so as to save labor, time, safety, economy, and economy. Effective, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

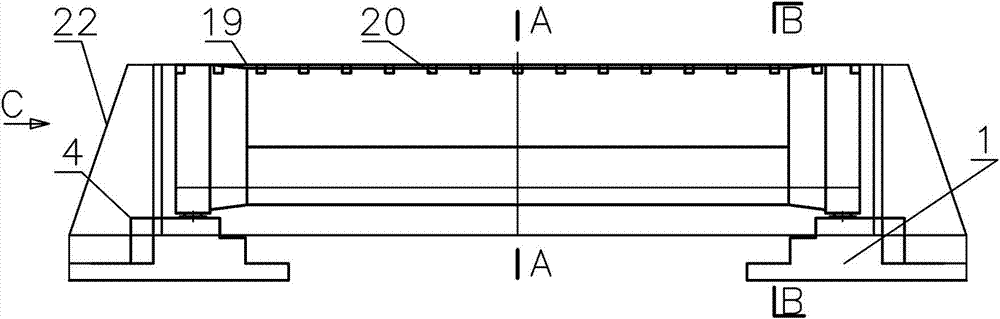

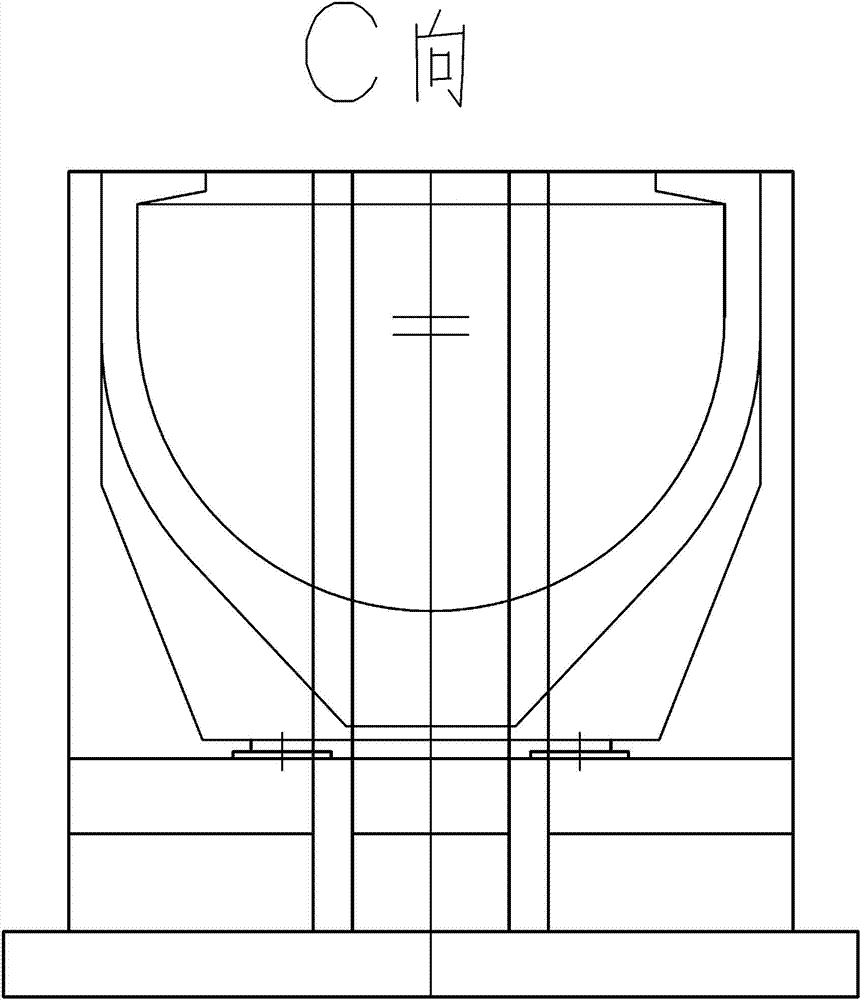

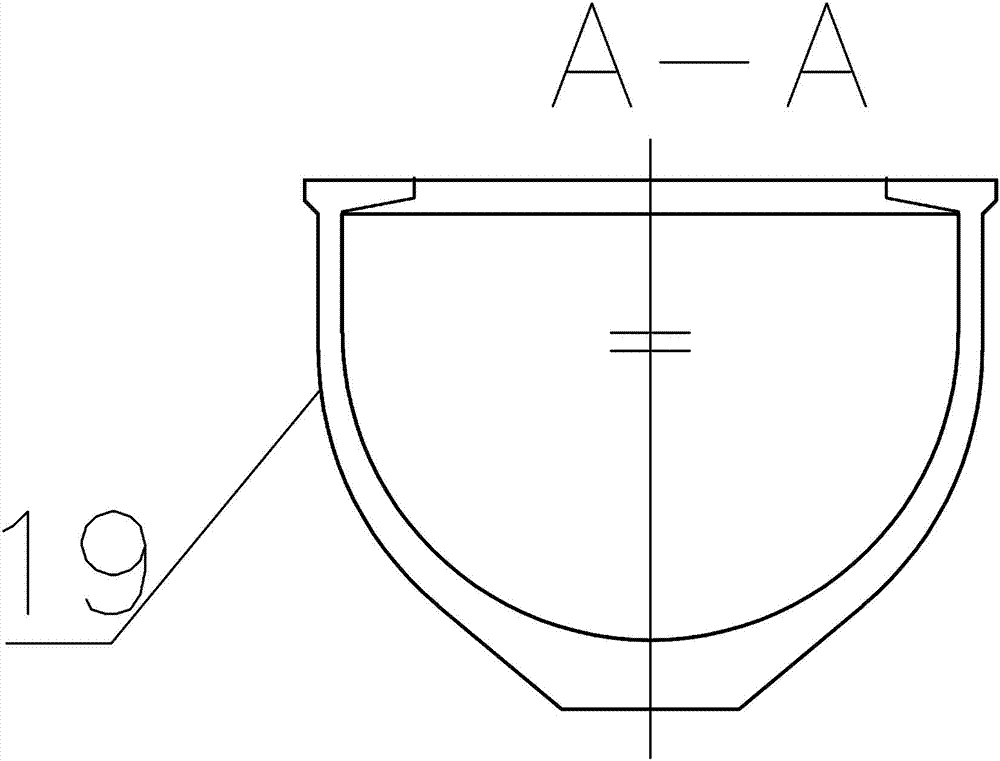

[0048] Such as Figure 1-4 In the test section 1:1 simulation test, the length of the aqueduct body 19 is 40m, and the dimensions of the inner space are 40.0m×9.0m×7.23m. The wall aqueduct and U-shaped aqueduct have a wall thickness of 350 mm and a weight of 1,600 tons. The first pier 1 and the second pier 4 are arranged at both ends of the tank body 19, and there are heads 22 on both sides. Beam 20.

[0049] Such as Figure 7 Among them, a U-shaped aqueduct simulation test device includes an outer mold 14 and an inner mold system. In the inner mold system, the inner mold 11 is movably suspended on a part of the inner beam 9 located in the outer mold 14,

[0050] Located outside one end of the outer mold 14, a plurality of track buttresses 5 are arranged, and on the track buttresses 5, track combined steel beams 6 are installed, and on the track combined steel beams 6, inner mold installation tracks 7 are installed;

[0051] The inner beam 9 is supported by the first leg 8 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com