Laminating method of touchpad and LCD (Liquid Crystal Display) panel

A touch panel and panel technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high operating strength, uneven force, poor bonding, etc., and achieve simple and fast operation and uniform force application , good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

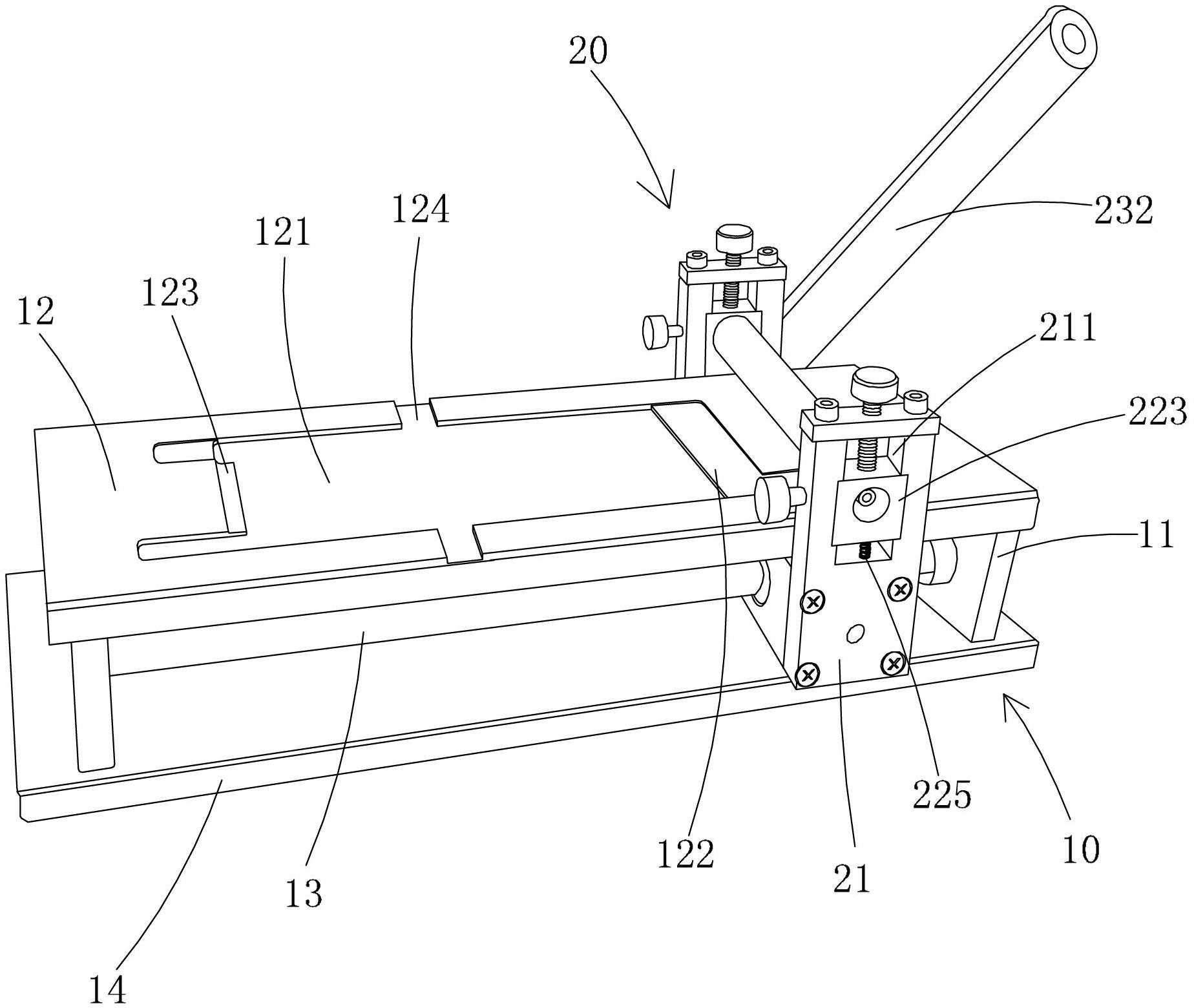

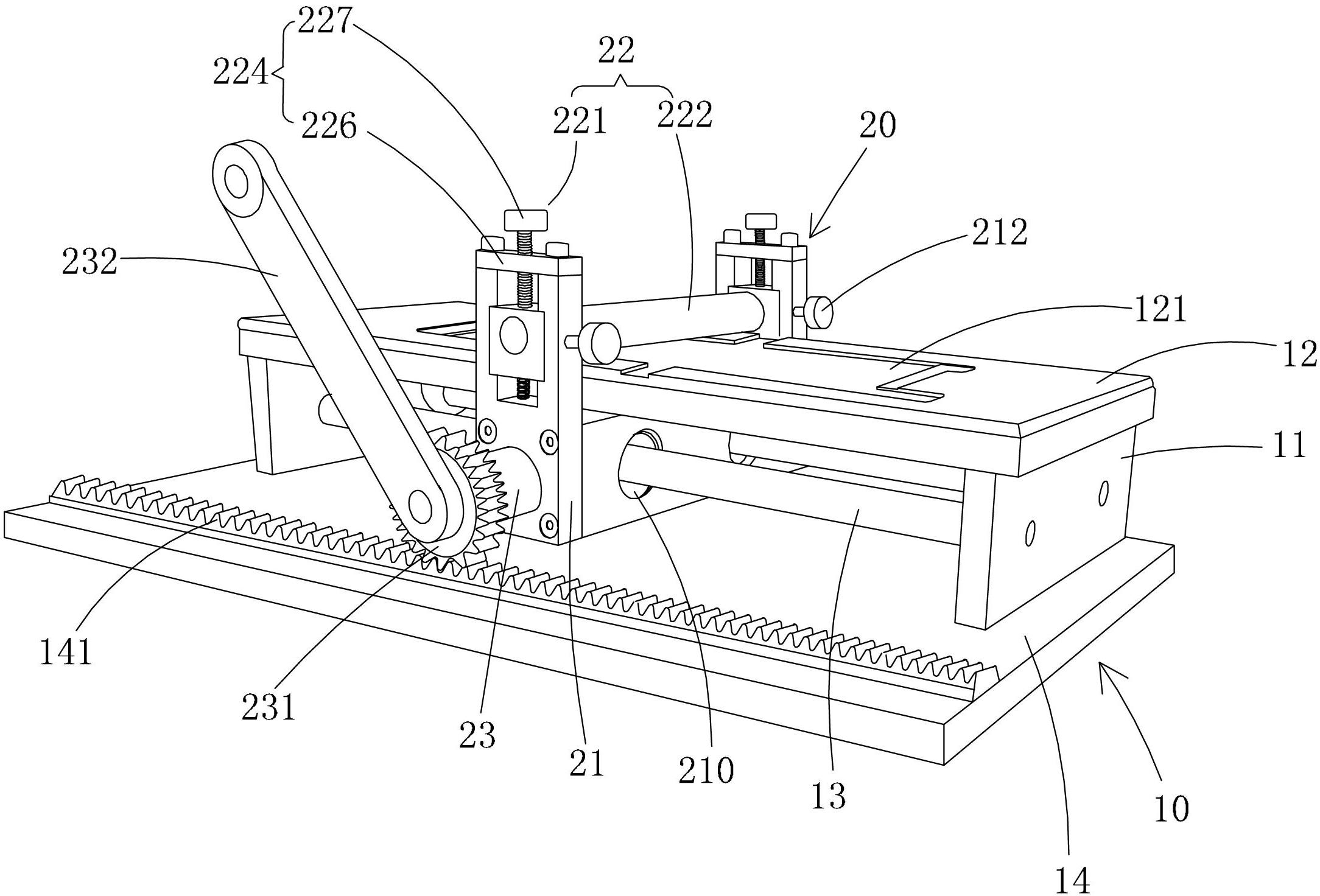

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

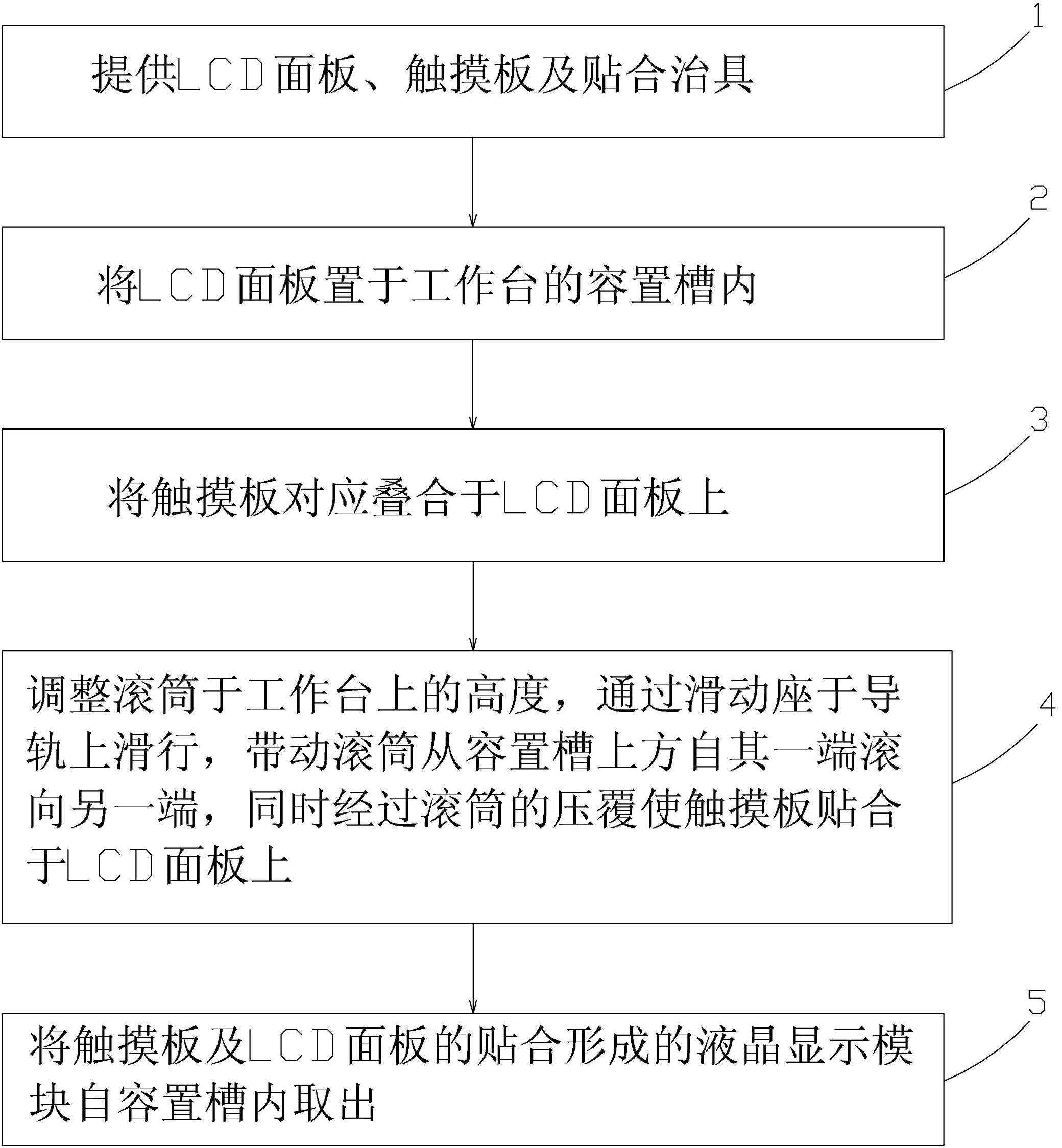

[0028] see figure 1 , and combined with Figure 2 to Figure 3 , the laminating method of touch panel of the present invention and LCD panel, comprises the following steps:

[0029] Step 1. Provide LCD panel, touch panel and bonding fixture.

[0030] Described lamination jig comprises: base 10, and the slide seat 20 that can slide relative to base 10 and be arranged on the base, base 10 comprises support frame 11, the workbench 12 that is installed on the support frame 11, and parallel The guide rail 13 installed on the support frame 11 under the workbench 12 . The workbench 12 can be a regular rectangle, and an accommodating groove 121 is arranged at the center of the workbench 12. The accommodating groove 121 can be made into various shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com