Rolling machine

A rolling mill and stand technology, applied in the direction of metal rolling, metal rolling, keeping roll equipment in an effective state, etc., can solve problems such as manual cleaning and affecting rolling efficiency, and achieve the effect of improving rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

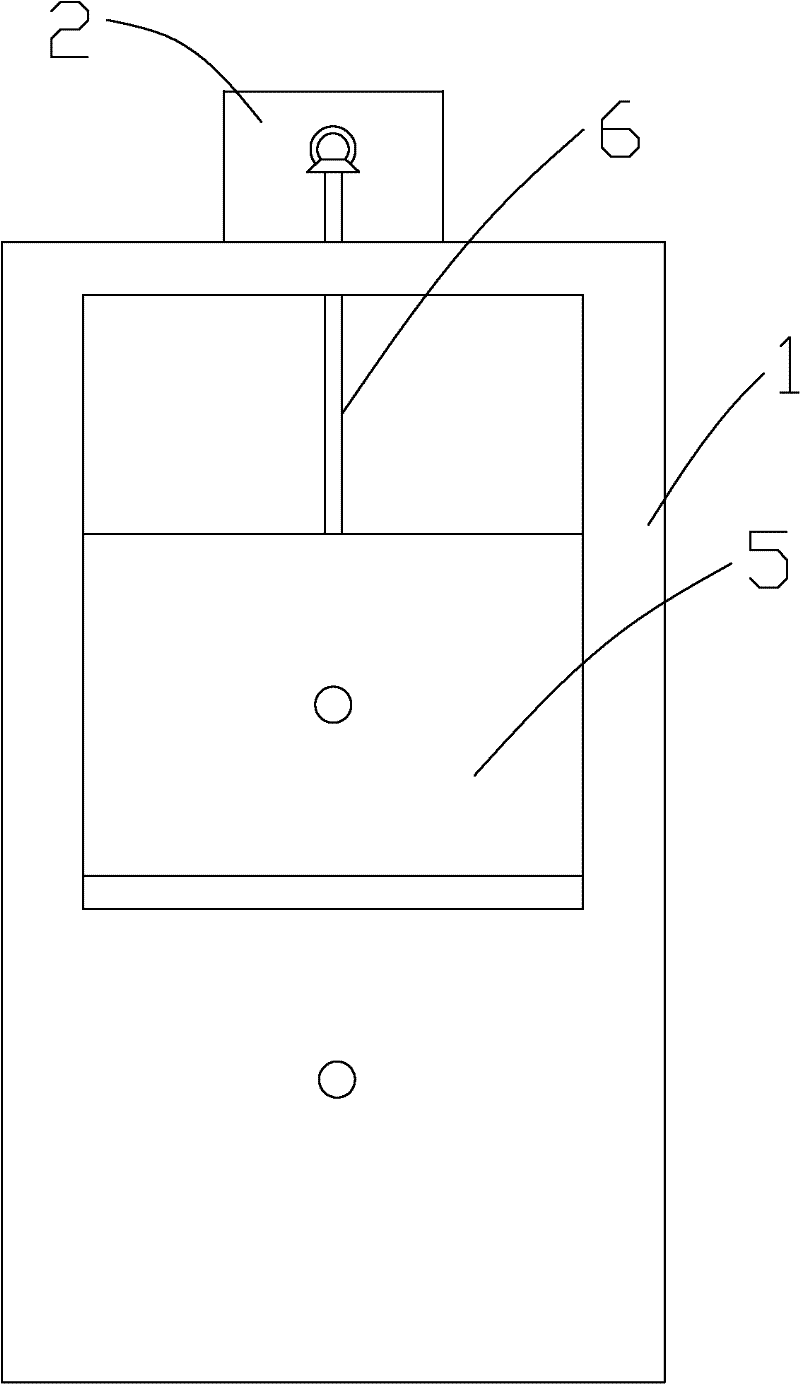

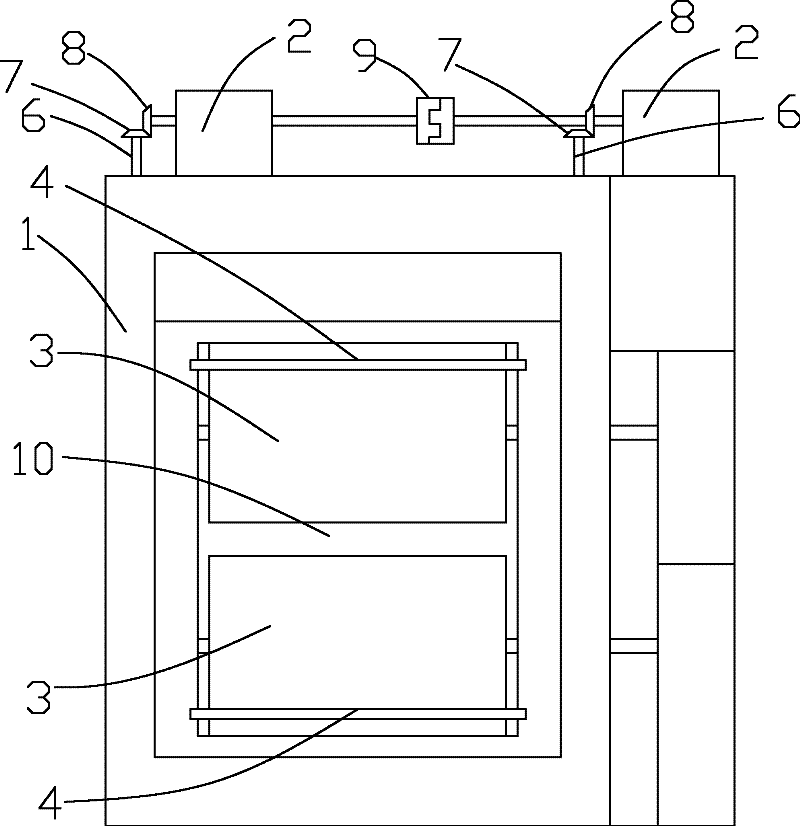

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] exist figure 1 and 2 Among them, a rolling mill, comprising a stand 1, a pair of rollers 3 arranged side by side on the stand 1 up and down and rotating in opposite directions, the axis lines of the rollers 3 are all arranged horizontally, and a rolling channel 10 is formed between the pair of rollers 3 , the metal material passes through the rolling passage 10, and is rolled into a suitable size by a pair of rollers 3 rotating in opposite directions. Blades 4 are respectively arranged above and below the rolling passage 10 on the stand 1, and the blade 4 of each blade 4 All extend along the axial direction of the roll 3 and are closely attached to the circumferential surface of the corresponding roll 3 . When the roll 3 rotates and rolls like this, the metal shavings attached on the roll 3 can be eradicated or removed by the blade of the blade 4 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com