Method for preparing anti-virus syrup

An anti-virus and syrup technology, applied in anti-viral agents, pharmaceutical formulas, medical preparations containing active ingredients, etc. The effect of complete liquid recovery and utilization, solving the problem of clarity, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In order to improve the clarity of the antiviral syrup, the present embodiment adopts the method of filtering, including the following two processes:

[0018] Process 1: A microporous membrane cartridge filter element made of polypropylene (pore diameter of 0.45 μm) is used for pump pressure filtration.

[0019] Although this method can guarantee the quality of liquid medicine clarity, etc., there is a problem of poor operability, because the liquid medicine is viscous and easy to block the filter element, which will gradually cause the filtration rate to be too slow, and finally cause the pressure to rise and cause the pump to overload and shut down . It takes about 5 hours to filter a batch of 1000L liquid medicine. During this period, the filter element needs to be cleaned 1 to 3 times to ensure the operability of the filtration and increase the chance of contamination of the liquid medicine.

[0020] Process 2: Use 208 twill fleece for natural filtration.

[0021]...

Embodiment 2

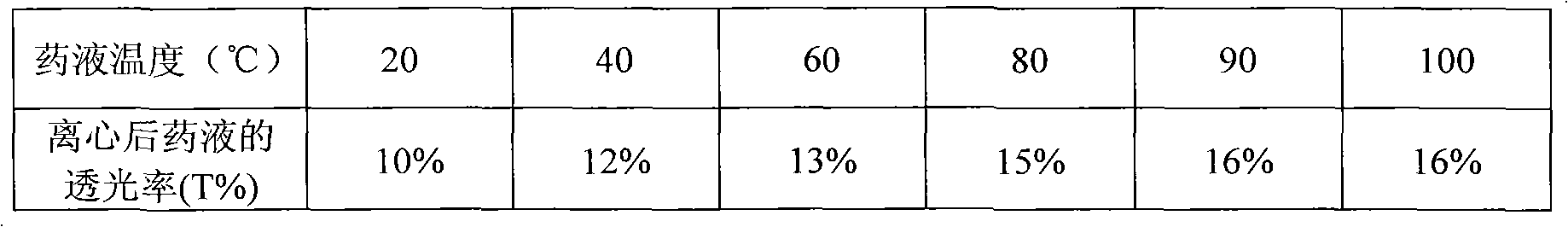

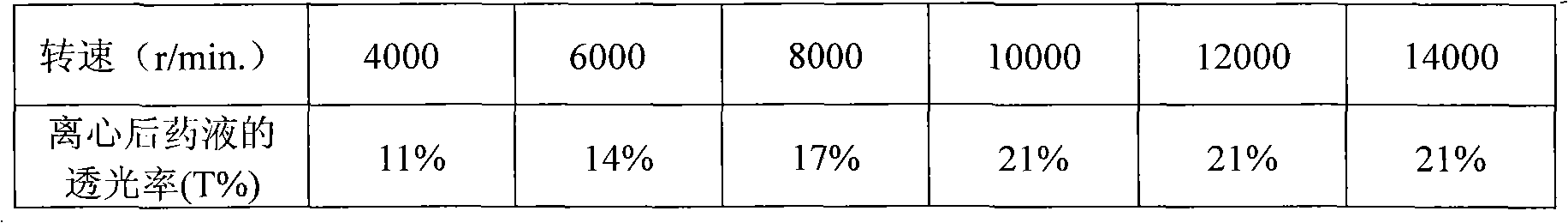

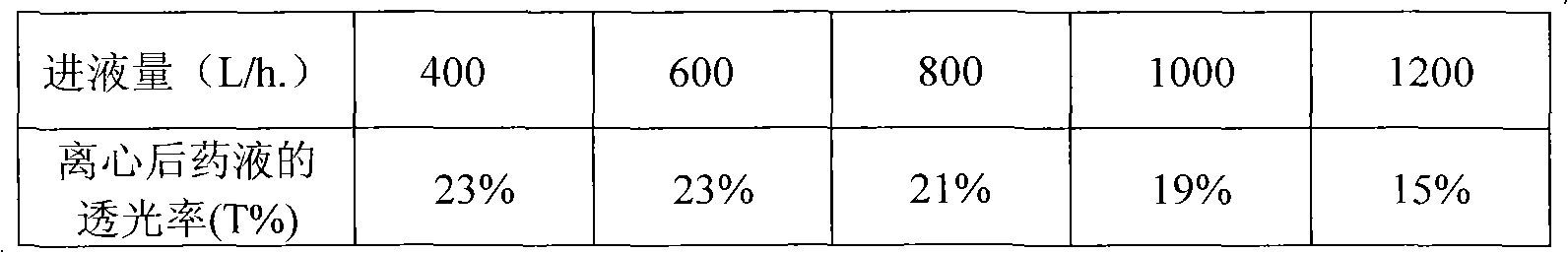

[0023] In this embodiment, high-speed centrifugation is used to improve the clarity of the antiviral syrup, and the equipment used is a traditional Chinese medicine clarification tubular high-speed separator (GQLB150-Z, Liaoning Liaoyang Sunshine Pharmaceutical Machinery Co., Ltd.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com