Lower charging type split type feeder and aquatic product greenhouse culture pond with same

A split-feeding machine technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of small range of activities, complex structure, excessive intensive damage, etc., to prevent feed waste, reduce the broken rate, and cover an area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

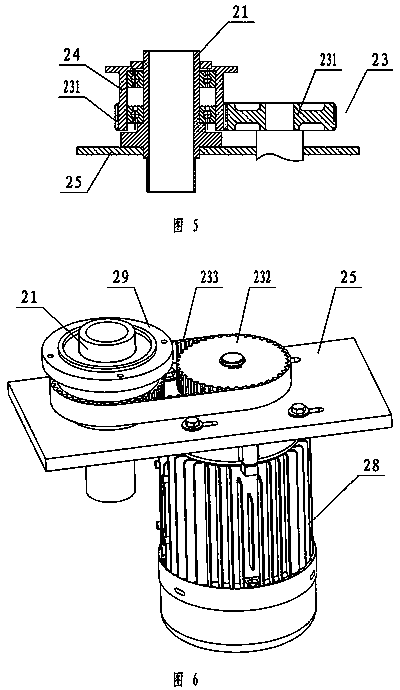

[0064] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-36 :

[0065] In the bottom feeding split type feeding machine of the present invention, a feeding mechanism 3 is arranged between the feeding mechanism 1 and the throwing mechanism 2, and the lower part of the throwing tray 22 of the throwing mechanism has a feeding port 2212, surrounded by There is a throwing port, the throwing disc is connected to the main shaft 21, and the discharge pipe 31 enters the feeding port 2212 of the throwing disc 22 or communicates with the feeding port; the negative pressure generated when the throwing disc 22 rotates sends the feeding mechanism 1 The granular feed is sucked into the throwing tray 22 from the feeding mechanism 3 and thrown out around. Described material throwing mechanism 2 mainly has following structure:

[0066] 1. The throwing disc 22 is connected to the main shaft 21, the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com