Multifunctional pruner

A pruning machine, multi-functional technology, applied in agricultural machinery and implements, cutting tools, cutting equipment and other directions, can solve the problems of danger, inflexible and reliable operation, rough locking button structure, etc., to achieve the effect of flexible locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

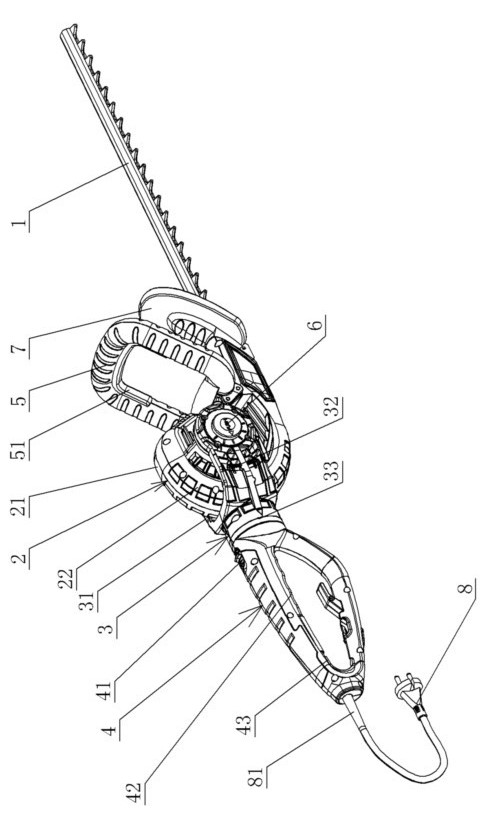

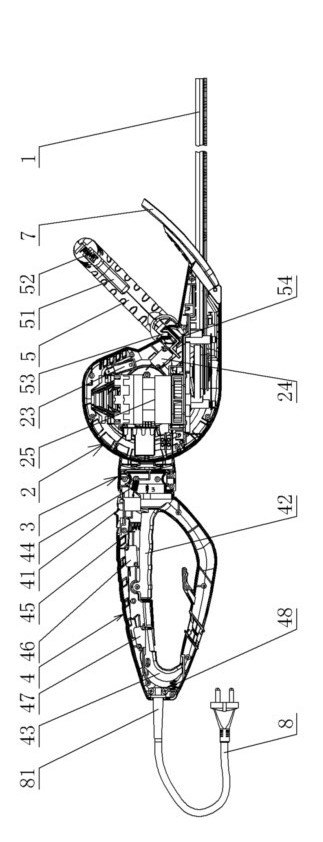

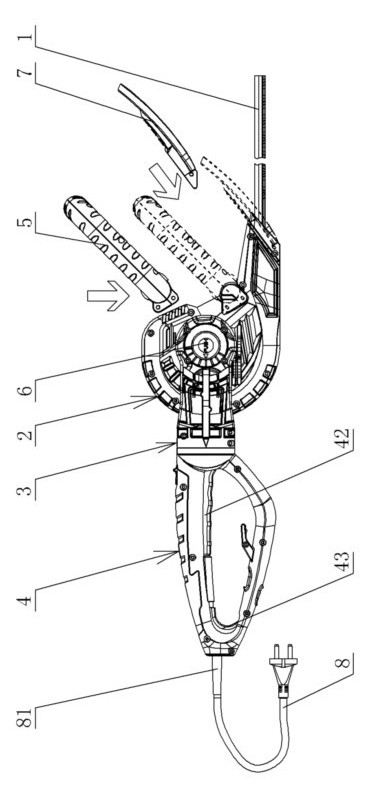

[0041] like Figure 1~Figure 24As shown, 1. blade assembly, 2. casing, 21. left casing, 211. left mounting hole, 22. right casing, 221. right mounting hole, 23. first micro switch, 24. second micro switch Dynamic switch, 25. Motor, 3. Connecting frame, 31. Left front connection end, 311. Left operation hole, 32. Right front connection end, 321. Right operation hole, 322. Tooth groove, 323. Tooth top surface, 33. Rear Connecting end, 34. Lock groove, 35. Limiting plate, 36. Ring groove, 37. Runner, 38. Runner cover, 381. Spring seat, 382. Gear ring groove, 39. Turning ring, 4. Main handle , 41. Self-locking push button, 411. Lock piece, 412. Self-locking block, 42. Main switch rocker arm, 43. Rear trigger, 44. Self-locking spring, 45. Main switch spring, 46. The third micro switch , 47. The fourth micro switch, 48. Trigger spring, 5. Secondary handle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com