Heating device for a fuel filter

A technology of fuel filter and heating device, which is applied in the direction of fuel heat treatment device, filtration separation, charging system, etc. It can solve the problems of engine stop, fuel filter clogging, power loss, etc., and achieve the effect of improving the spring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

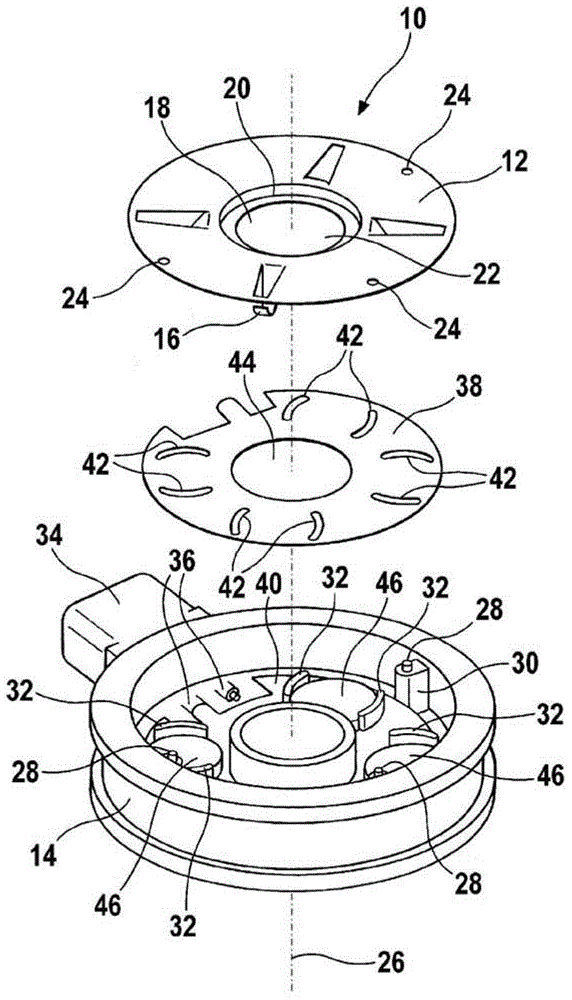

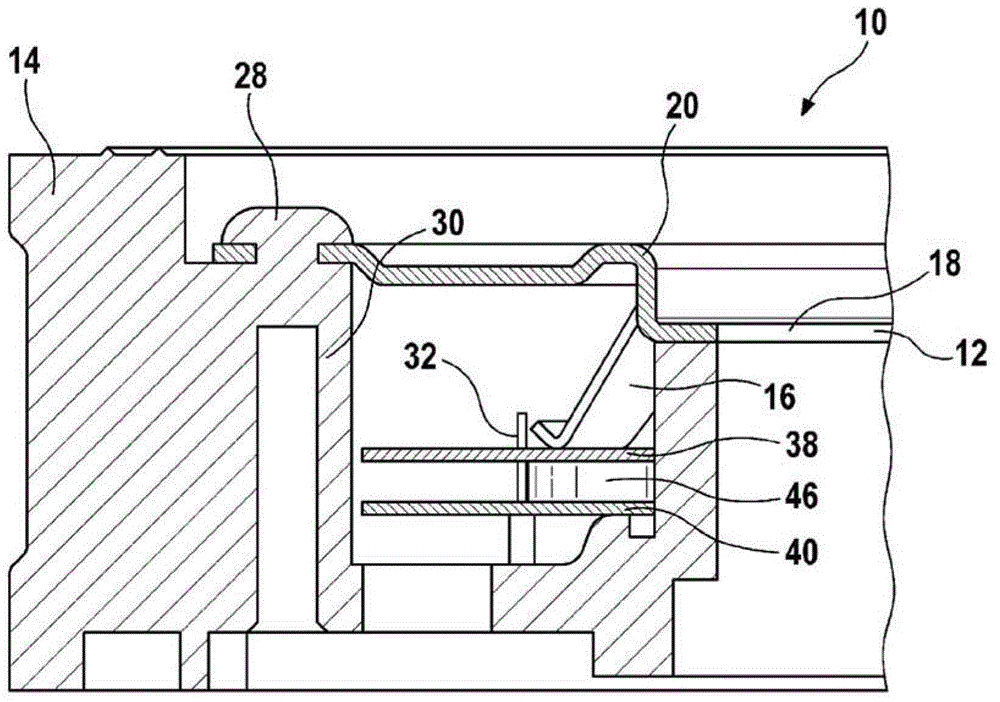

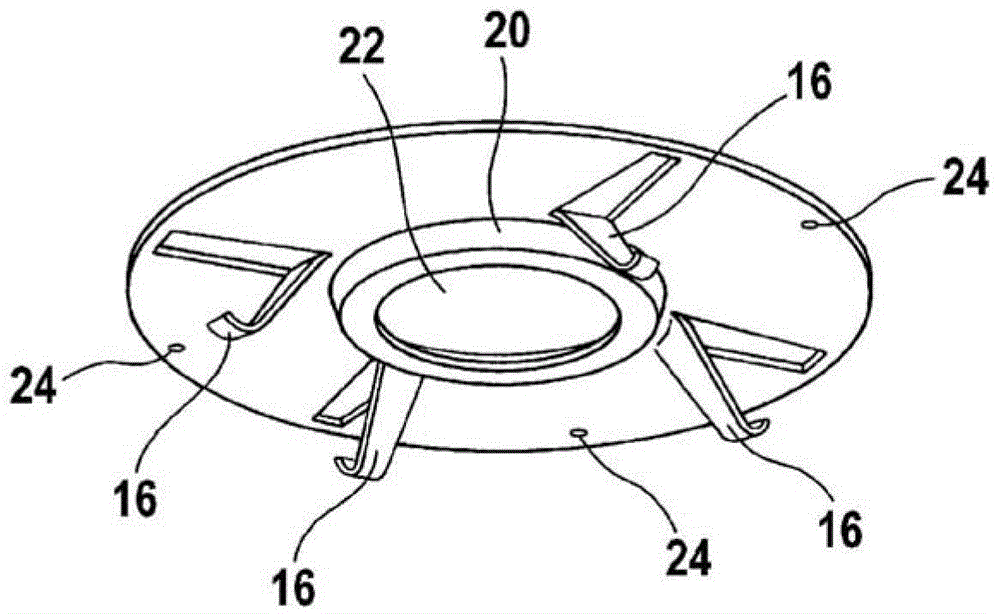

[0033] According to the heating device 10 of the present invention, the figure 1 and 2 As can be seen in , it comprises a disc-shaped cover 12 which largely closes a cup-shaped housing 14 .

[0034] A plurality, now four, of arms 16 are formed on the cover 12 . Cover 12 and arm 16 are constructed of spring steel.

[0035] The cover 12 has an embossed recess 20 and an opening 22 in a central region 18 . The recess 20 increases the bending stiffness of the cover 12 in its central region 18 . Opening 22 is designed for a fluid, currently fuel, to flow through during operation of heating device 10 .

[0036] On the radially outer area of the cover 12 , a plurality, at least three, of openings 24 are provided circumferentially. One pin 28 protrudes through opening 24 in the direction of longitudinal axis 26 of housing 14 . The pins 28 are formed on sockets 30 which are formed in the lower, inner corner region of the cup-shaped housing 14 distributed over the circumference o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com