Laundry dryer having a condensate collector

A condensate and dryer technology, which is used in household dryers, household appliances, washing devices, etc., can solve problems such as frequent cleaning and lint blockage, and achieve the effect of suppressing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

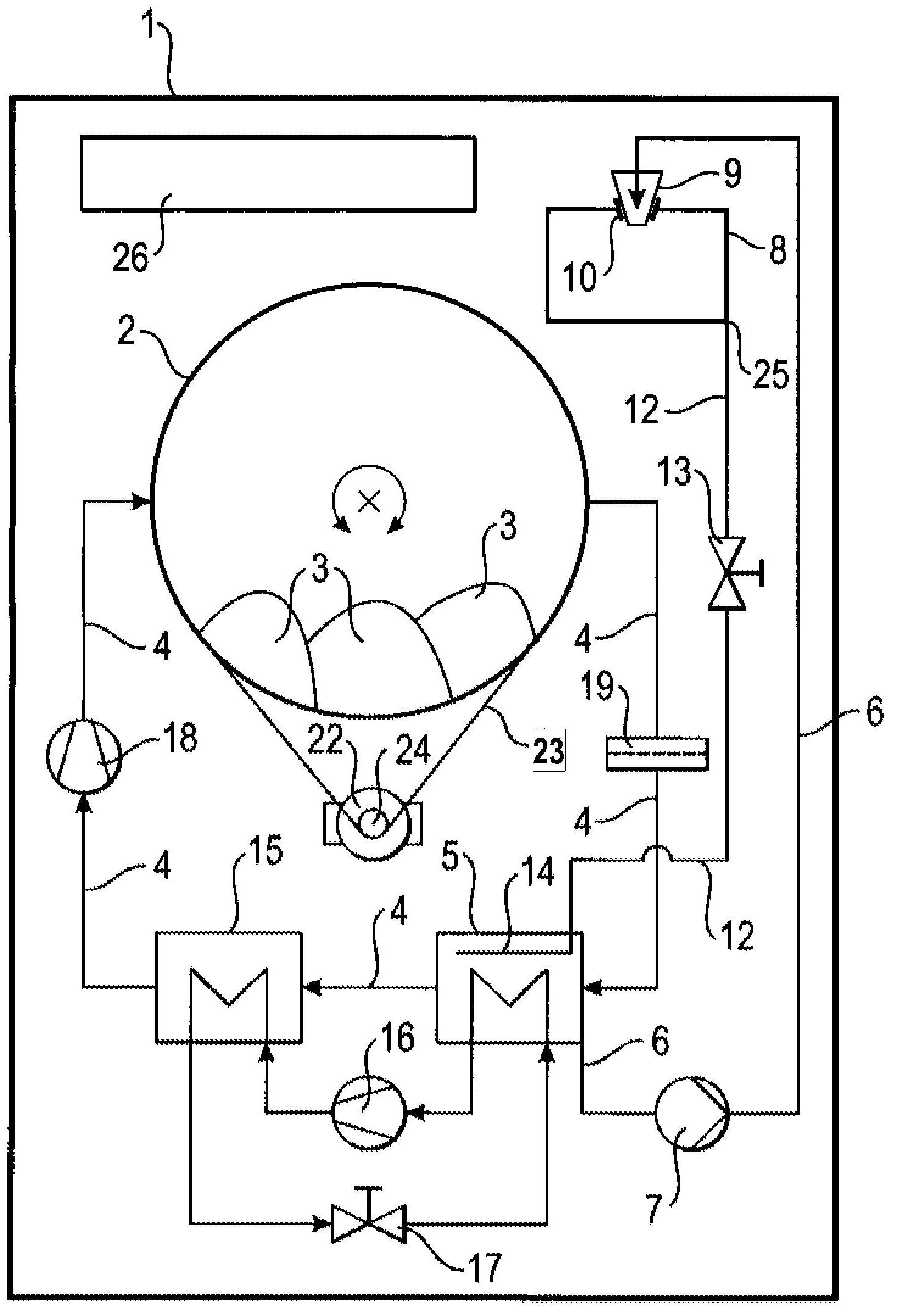

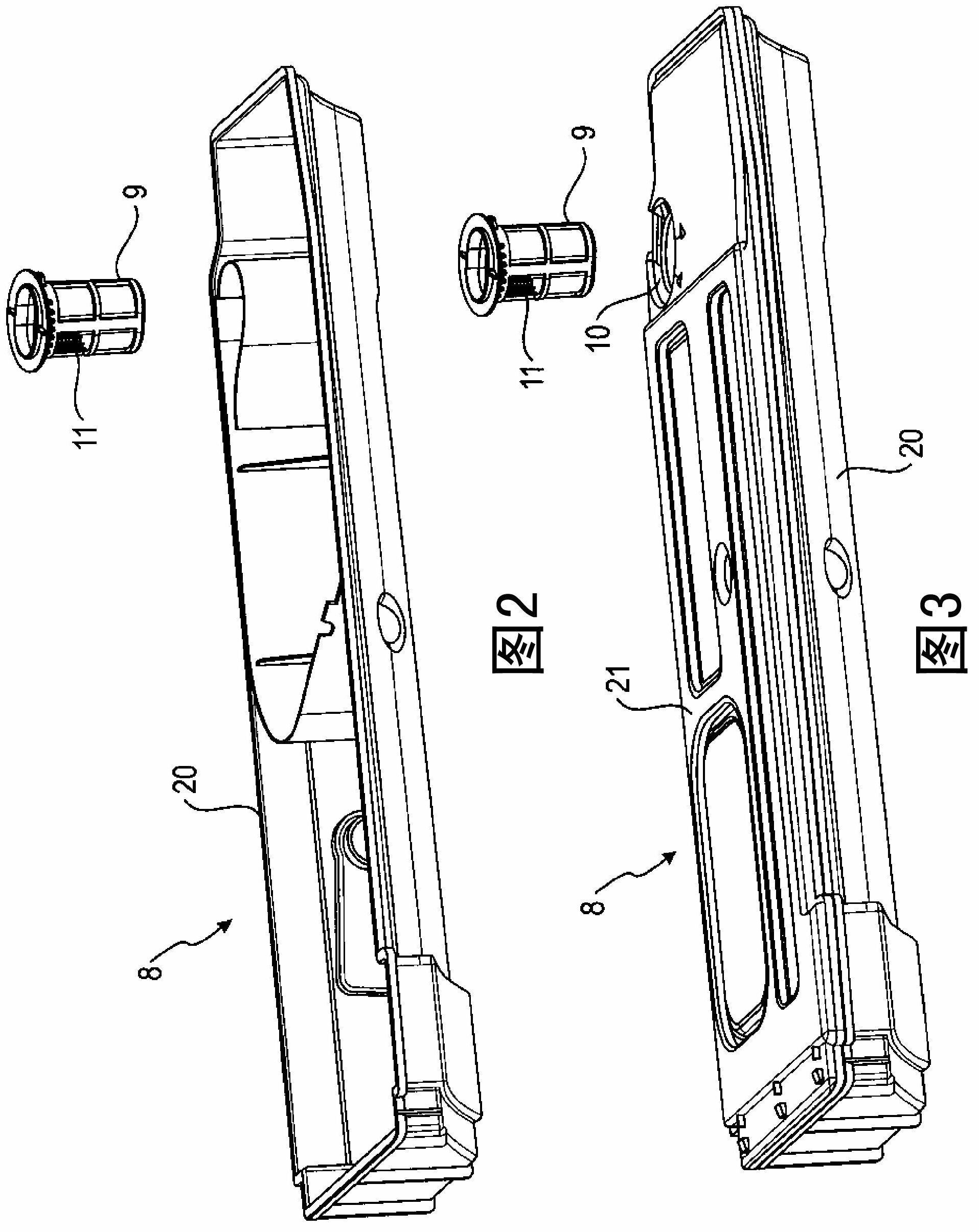

[0044] First, see figure 1 The basic design of a dryer 1 , embodied here as a laundry dryer 1 , is described. The dryer comprises a drying chamber 2 which is embodied as a rotatable drum 2 and which houses items 3 to be dried, ie wet laundry 3 . Treatment air is guided through the drying chamber 2 around the laundry 3 in a closed circuit defined by the treatment air channel 4 . The process air channel 4 comprises means for driving the process air, in particular a blower 18 , and means for heating the process air, in particular a heat source 15 , before it is introduced into the drying chamber 2 . The process air line also comprises means for cooling the process air after it has passed through the drum 2 , in particular a heat sink 5 .

[0045] When the process air is guided through the heat absorber 5, the moisture collected by the process air as it flows along the wet laundry 3 is precipitated from the process air as liquid condensate because, when the process air flows thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com