Cutter blade head for fiber roving chopper

A shredder, blade technology, applied in the direction of fiber bundles into fiber sliver/yarn, non-bundle formation, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

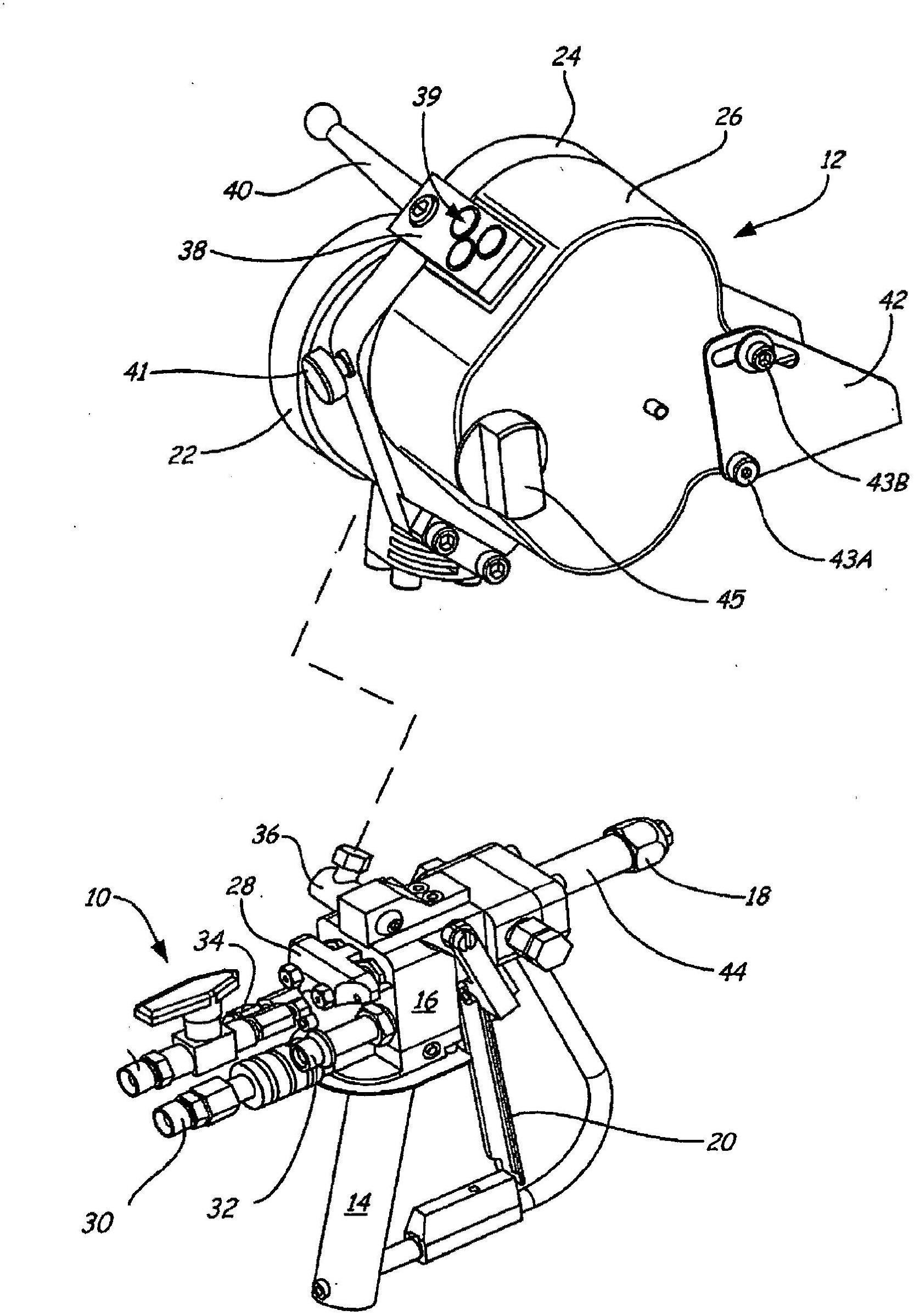

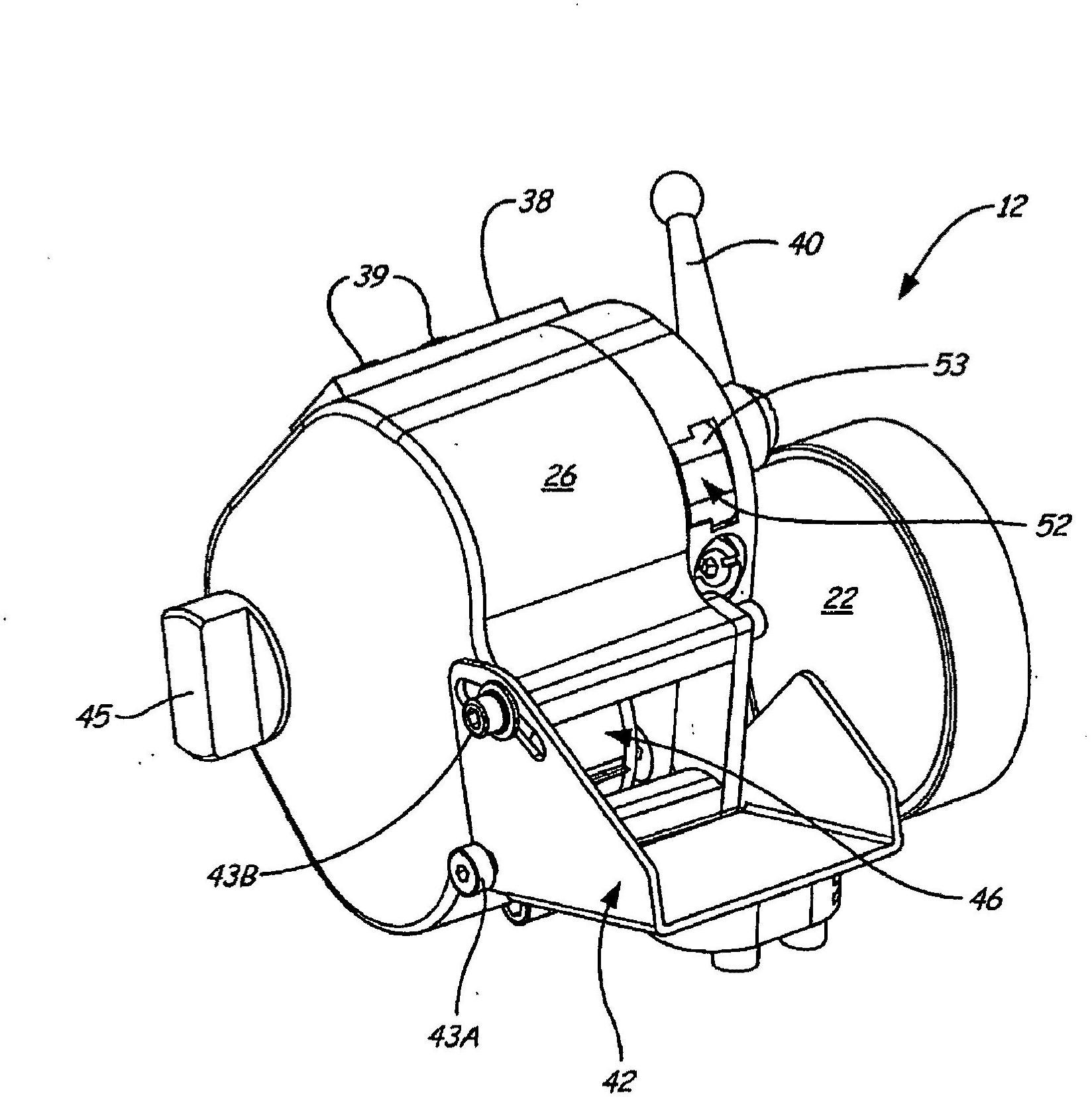

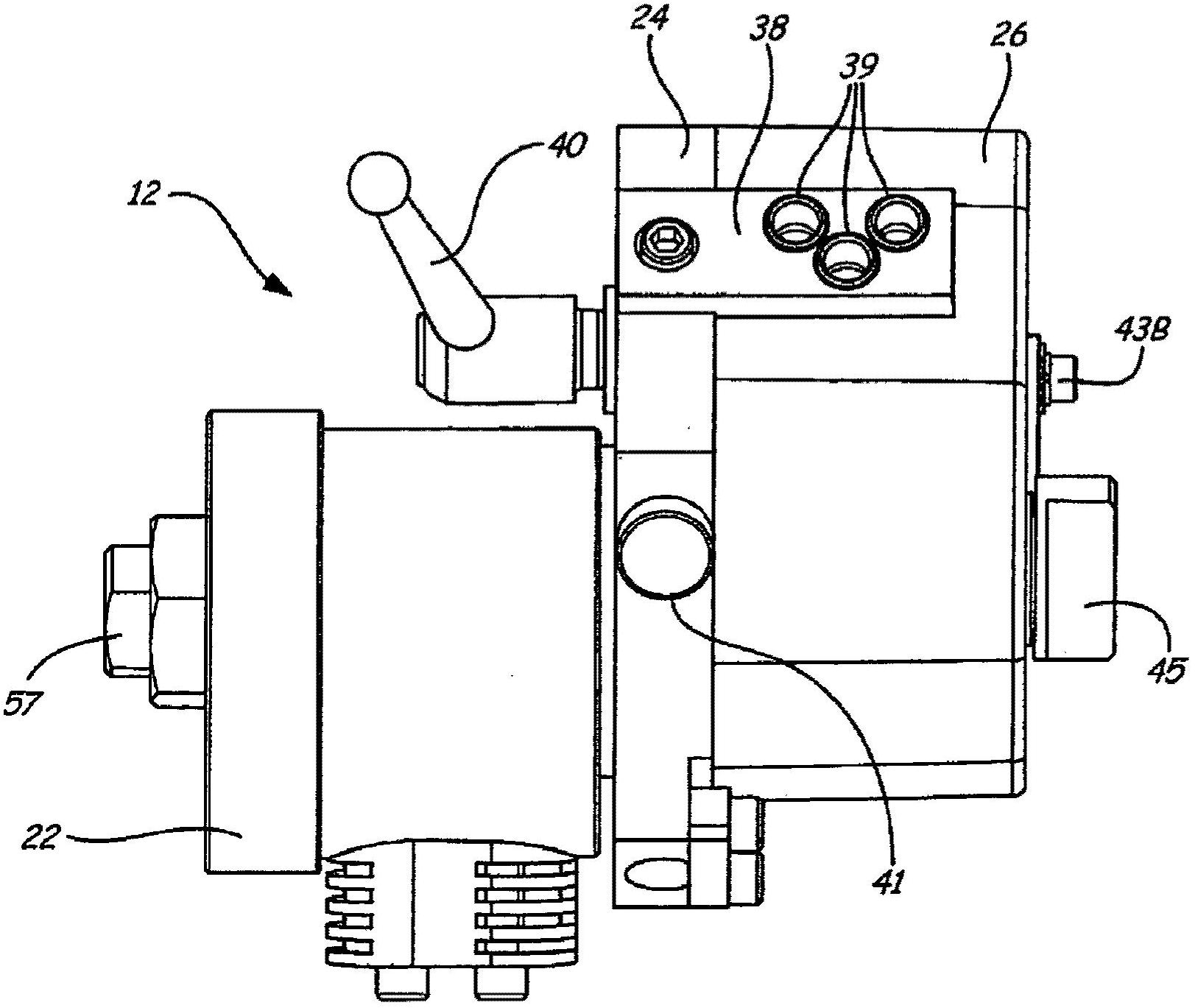

[0023] figure 1 is an exploded view of the assembly of a liquid spray gun and a fiber roving chopper in which the anvil assembly of the present invention is used. exist figure 1 , the fiber roving chopper 12 is shown slightly enlarged relative to the liquid spray gun 10 . The liquid spray gun 10 includes a two-component internal mixing gun having a handle 14 , a valve body 16 , a nozzle 18 and a trigger 20 . The fiber roving chopper 12 includes an air motor 22 , a housing 24 and a cover 26 . The valve body 16 of the spray gun 10 includes a valve assembly 28 , an air inlet 30 , a material inlet 32 , a catalyst inlet 34 and an air outlet 36 . Housing 24 of fiber roving chopper 12 includes fiber inlet 38 , opening 39 , lever 40 , knob 41 , fasteners 43A and 43B, knob 45 and cover 26 , which includes distribution chute 42 .

[0024] In the illustrated embodiment, spray gun 10 comprises a two-component mixing spray gun that receives two liquid components that, when dispensed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com