High-voltage large-current transient automatic discharge switch capable of presetting gaps

An automatic discharge, high voltage technology, applied in the direction of circuits, spark gaps, electrical components, etc., can solve the problems of poor controllability and safety, long discharge time and travel, and affect system stability, etc., to achieve easy movement and Flexible placement, short turn-on time, increased discharge reliability and predictable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are described with reference to the accompanying drawings.

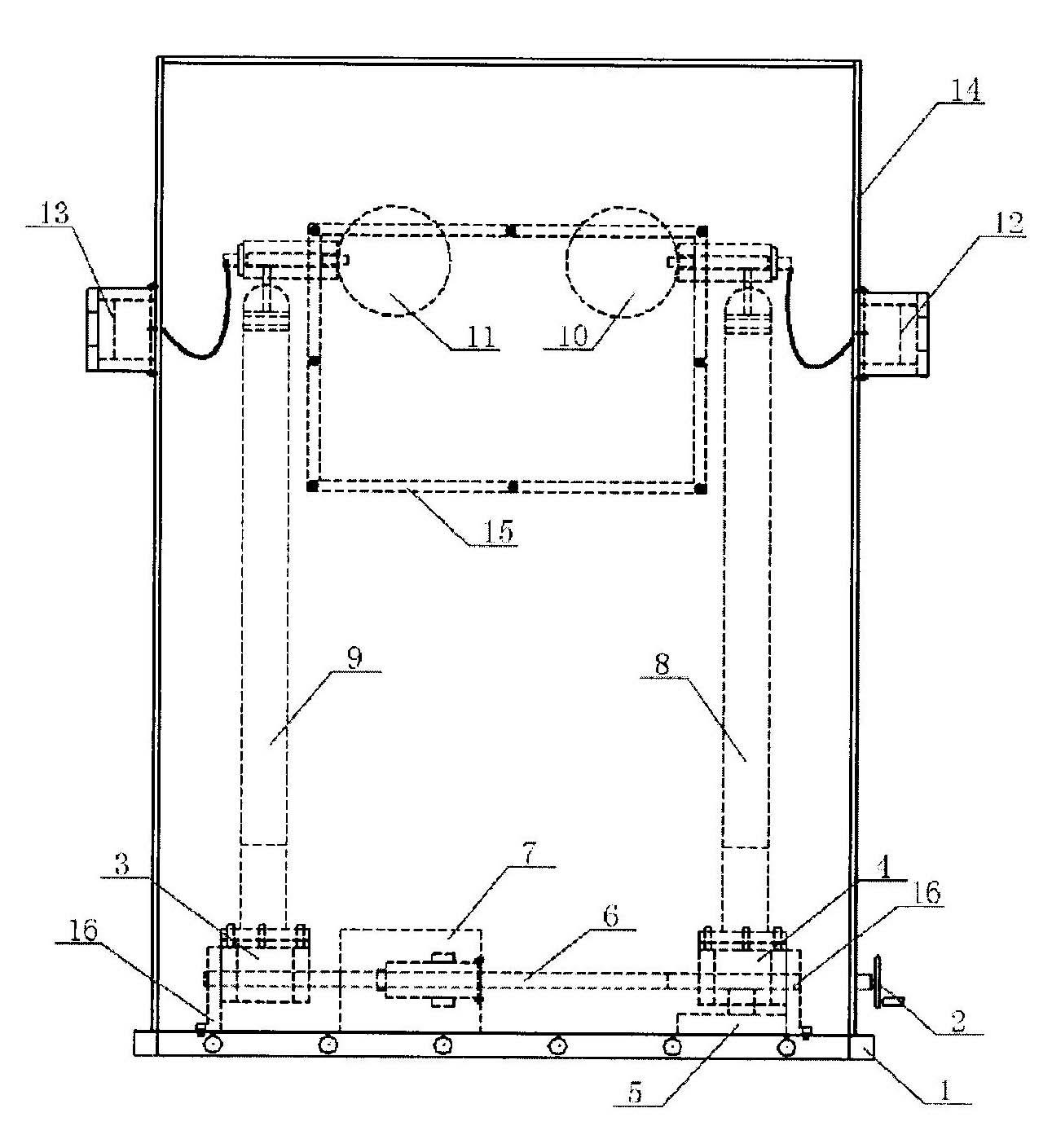

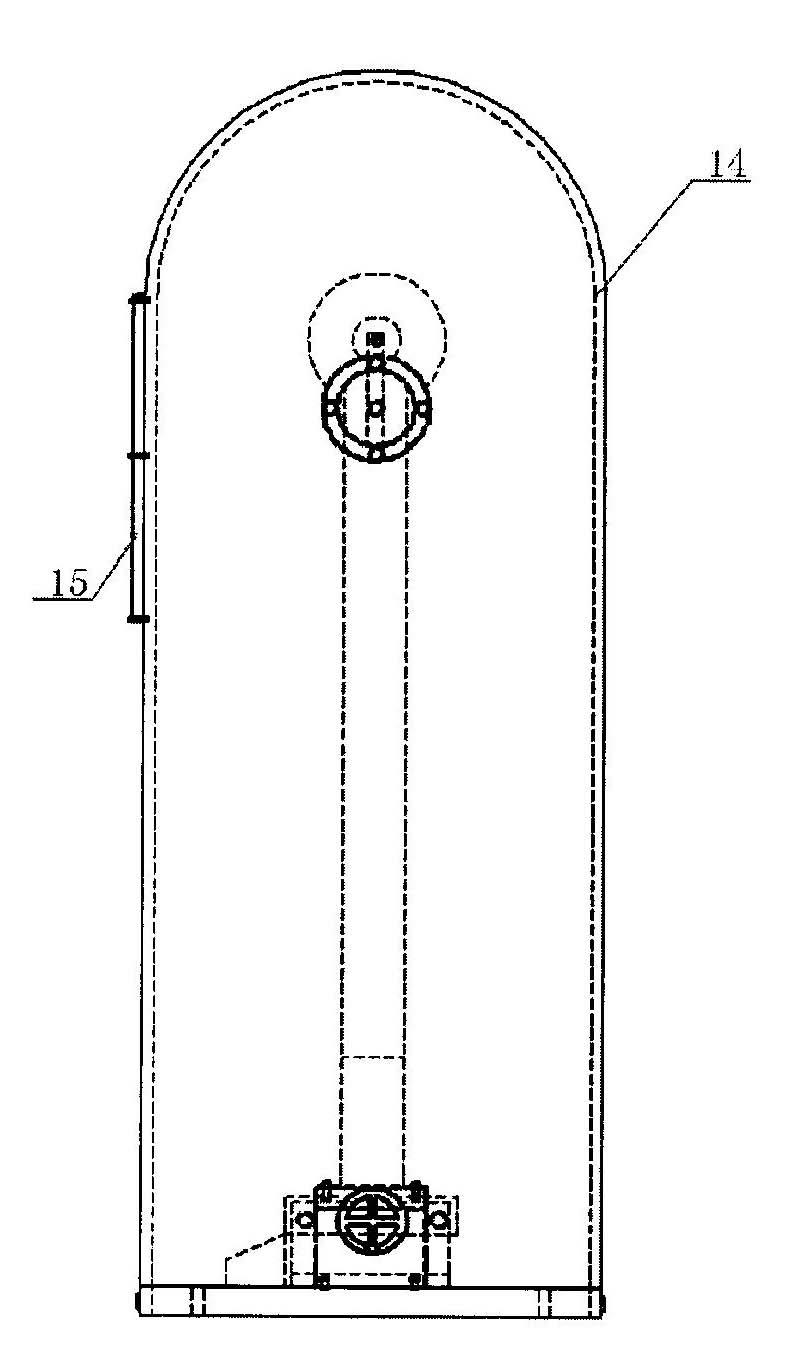

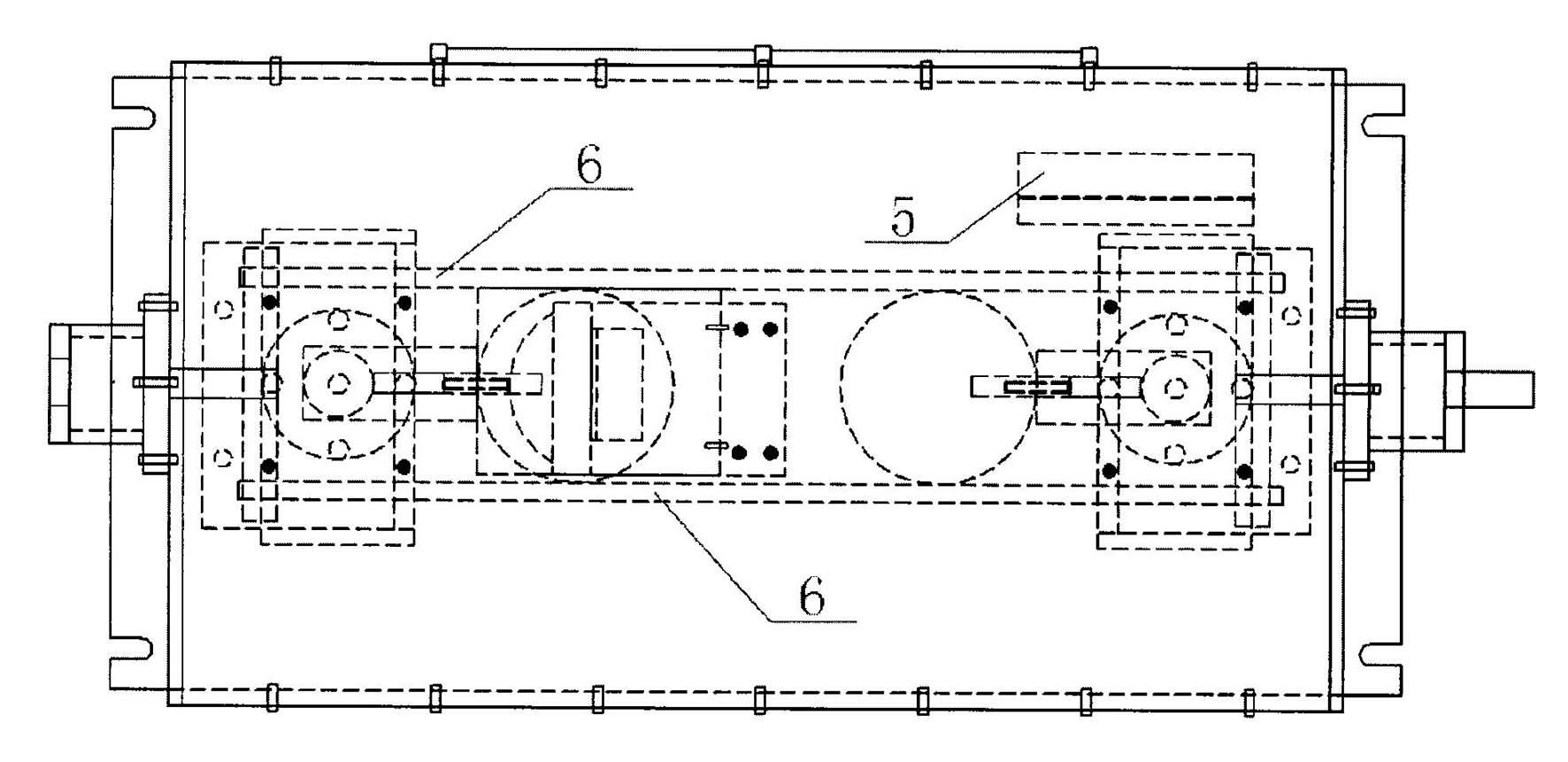

[0020] as attached figure 1 As shown: the discharge switch includes a pair of left and right hollow round copper balls and a switch base, wherein the left ball is an electric ball 11, the right ball is a manual ball 10, and one end of the electric ball 11 is provided with a high-voltage input interface 13, and the manual ball One end of 10 is provided with a high-voltage output interface 12. By controlling the movement of the electric ball 11, the discharge switch forms a variable ball gap switch during charging and discharging. An electric device, a manual device and a guide rail 6 are arranged on the switch base 1, and the two ends of the guide rail 6 pass through the positioning plate 16 Fixed on the switch base 1, the electric device is located at the left end of the guide rail 6. The electric device includes a left slider 4 and an electromagnet 7, the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com