Micro control unit (MCU) built-in reference temperature compensation method based on system on chip (SOC) electric meter

A technology of reference temperature and compensation method, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problem of high price, and achieve the effect of low cost, strong operability, and reducing temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

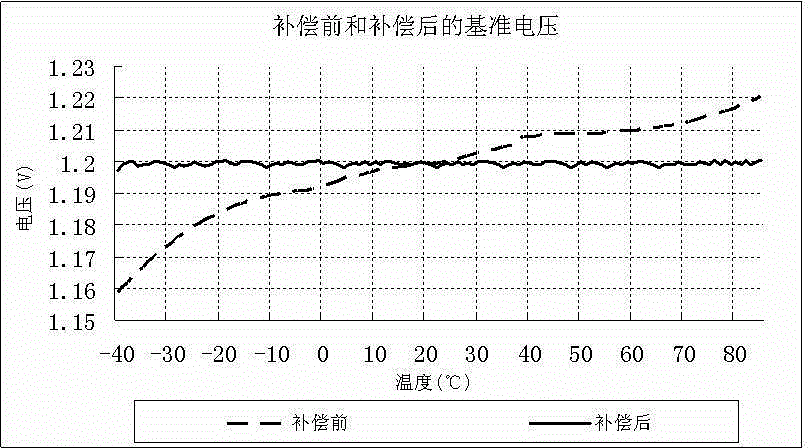

[0025] The first thing that the inventive method will do is to set up the temperature compensation data table, can be done according to the following steps during concrete implementation:

[0026] a. First place the meter in a temperature-adjustable high and low temperature box to work. We can first set an ambient temperature range. This range should be the possible temperature range of the meter’s working environment, such as -40°C to +80°C ℃, and then according to the principle of temperature from low to high, first set the high and low temperature box at -40 ℃, after the temperature is stable, use a high-precision digital multimeter to measure and record the output voltage value of the MCU built-in reference, which is recorded as u(- 40);

[0027] b. Calculate the MCU built-in reference voltage error e(-40),

[0028] The applicable formula is: e(-40)=u(-40)-u 0 ,

[0029] where u 0 It is the calibrated output value of the MCU built-in reference at room temperature (25 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com