Anti-oxidation anti-gassing transformer oil

A transformer oil and anti-gassing technology, applied in the field of transformer oil, can solve the problems of short service life and unstable anti-gassing performance, and achieve the effects of improving gas-gassing resistance, improving oxidation stability and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

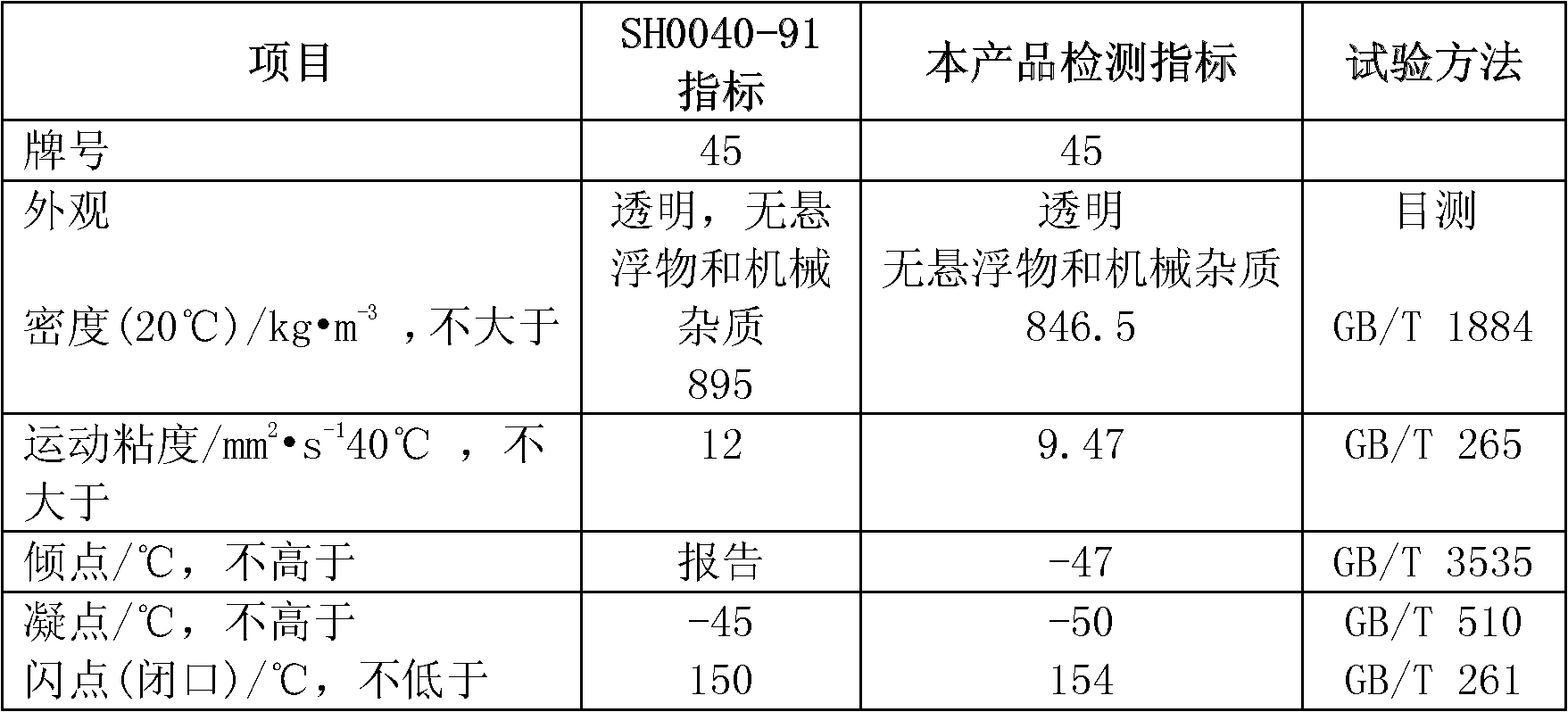

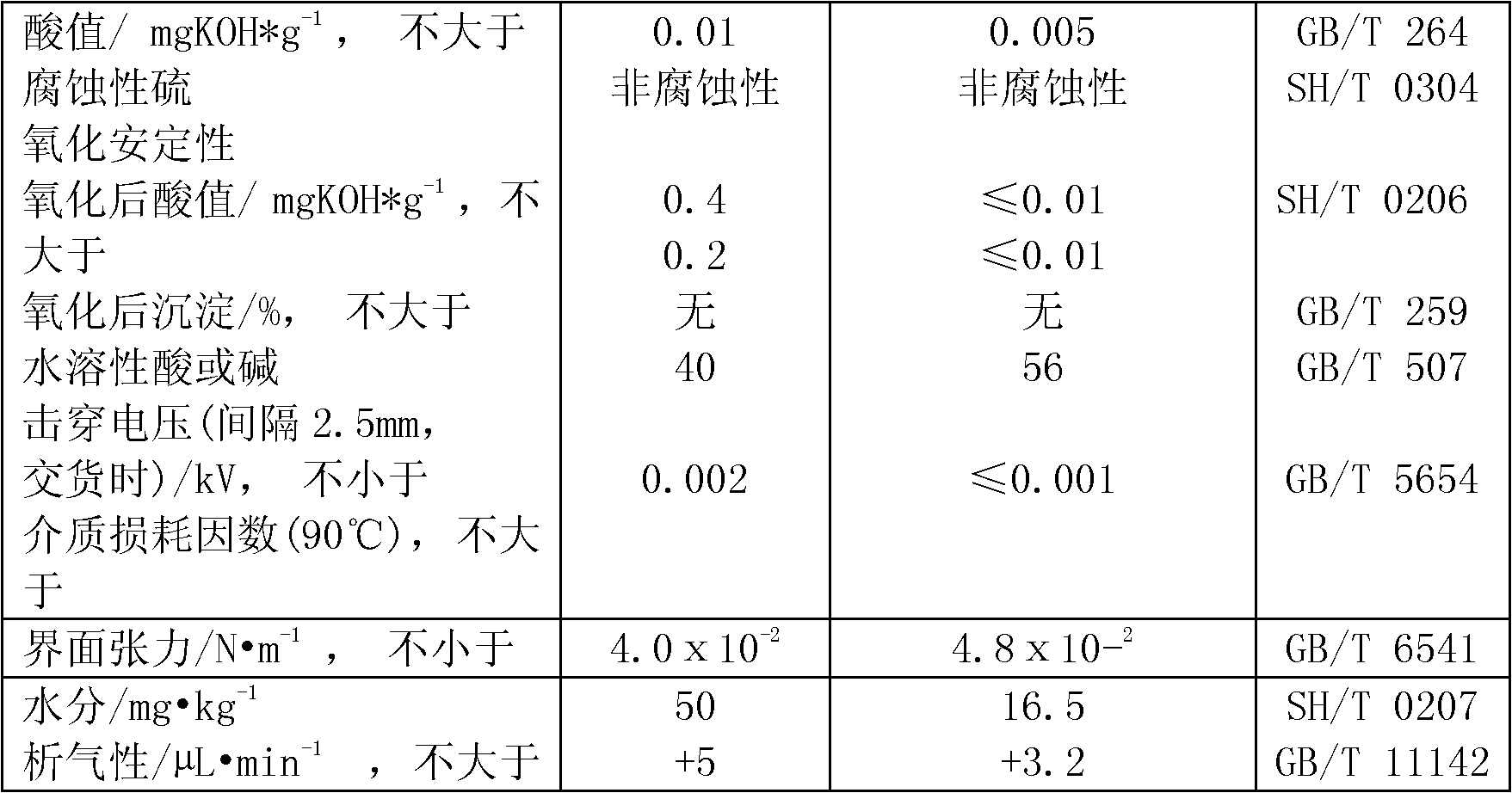

Image

Examples

Embodiment 1

[0017] Raw materials: 0.08% of antioxidant 2,6-di-tert-butyl-p-cresol, 0.05% of metal deactivator benzotriazole and its derivatives, 20% of anti-gassing additive, and the balance is paraffin-based refined mineral oil.

[0018] The preparation method is as follows: heat paraffin-based refined mineral oil to about 50-60°C, first add 0.08% of 2,6-di-tert-butyl-p-cresol and stir evenly, then add 0.05% of benzotriazole and Its derivatives and 20% anti-gassing additives are stirred evenly, filtered and put into storage.

[0019] Wherein the preparation method of the anti-gassing additive is as follows: the anti-gassing additive adopts the distillate of petroleum at normal temperature as a raw material, and the components (percentage by weight) are nickel 2.5%, copper 0.25%, aluminum oxide 25.25% and aluminum oxide-silicon oxide 72%. The catalyst is subjected to hydrogenation treatment, and the product obtained after treatment is usually separated into a distillate product at 280°C t...

Embodiment 2

[0021] Raw materials (percentage by weight): 0.08% of antioxidant 2,6-di-tert-butylphenol, 0.3% of metal deactivator mercaptobenzotriazole and its derivatives, 30% of anti-gassing additive, and the balance is cycloalkane Refined mineral oil base.

[0022] The preparation method is as follows: heat naphthenic refined mineral oil to about 50-60°C, first add 0.08% of 2,6-di-tert-butylphenol and stir evenly, then add 0.3% of mercaptobenzotriazole and Its derivatives and 30% anti-gassing additives are stirred evenly, filtered and put into storage.

[0023] Wherein the preparation method of the anti-gassing additive is as follows: the anti-gassing additive adopts petroleum normal temperature distillate as raw material, and is nickel 3.5%, copper 0.35%, aluminum oxide 25% and aluminum oxide-silicon oxide 71.15% with component (weight percentage) The catalyst is subjected to hydrogenation treatment, and the product obtained after treatment is usually separated into a distillate produ...

Embodiment 3

[0025] Raw materials (percentage by weight): antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.08%, metal deactivator thiadiazole and its derivatives 0.5% %, anti-gassing additive 10%, and the balance is paraffin-based refined mineral oil.

[0026] The preparation method is as follows: heat the paraffin-based refined mineral oil to about 50-60 ° C, first add 0.08% of antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid n-octadecyl alcohol After the ester is stirred evenly, 0.5% of thiadiazole and its derivatives and 10% of anti-gassing additives are sequentially added, stirred evenly, filtered and stored.

[0027] Wherein the preparation method of the anti-gassing additive is as follows: the anti-gassing additive adopts petroleum normal temperature distillate as raw material, and is nickel 2.7%, copper 0.3%, aluminum oxide 30% and aluminum oxide-silicon oxide 67% with component (weight percentage) The catalyst is subjected to hydrogenation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com