Formula of hydrogen absorption type fiber paste and manufacture method thereof

A fiber paste, hydrogen type technology, applied in the petroleum industry, additives, lubricating compositions, etc., to achieve good hydrogen absorption performance and prevent harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

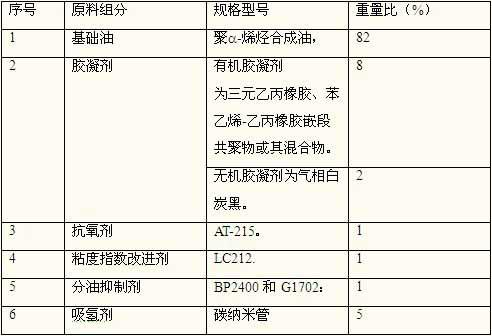

[0036] The typical formula of the hydrogen-absorbing fiber paste of the present invention is as follows:

[0037]

[0038] 1. The base oil is poly-a-olefin synthetic oil, which has excellent high and low temperature characteristics and low volatility.

[0039] 2. The gelling agent adopts an organic-inorganic composite gelling agent; the organic gelling agent is EPDM rubber, styrene-ethylene propylene rubber block copolymer or a mixture thereof. The inorganic gelling agent is fumed white carbon black. The use of organic-inorganic composite gelling agent can make the structure of the paste more stable, and can achieve a balance between reducing oil separation and improving fluid acceptance.

[0040] 3. Antioxidant is AT-215. The main antioxidant tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester (referred to as 1010) and the auxiliary antioxidant tris(2,4 One di-tert-butylphenyl) ester (abbreviated as 168) compound antioxidant AT215 comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com