Novel small-scale drying line for ceramic tile uniformly-distributed array mould-charging paster

A small-sized, die-stick technology, applied in the field of tile packaging, can solve the problems of unsatisfactory packaging equipment design, and achieve the effects of saving manpower and material resources, simple and compact structure, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

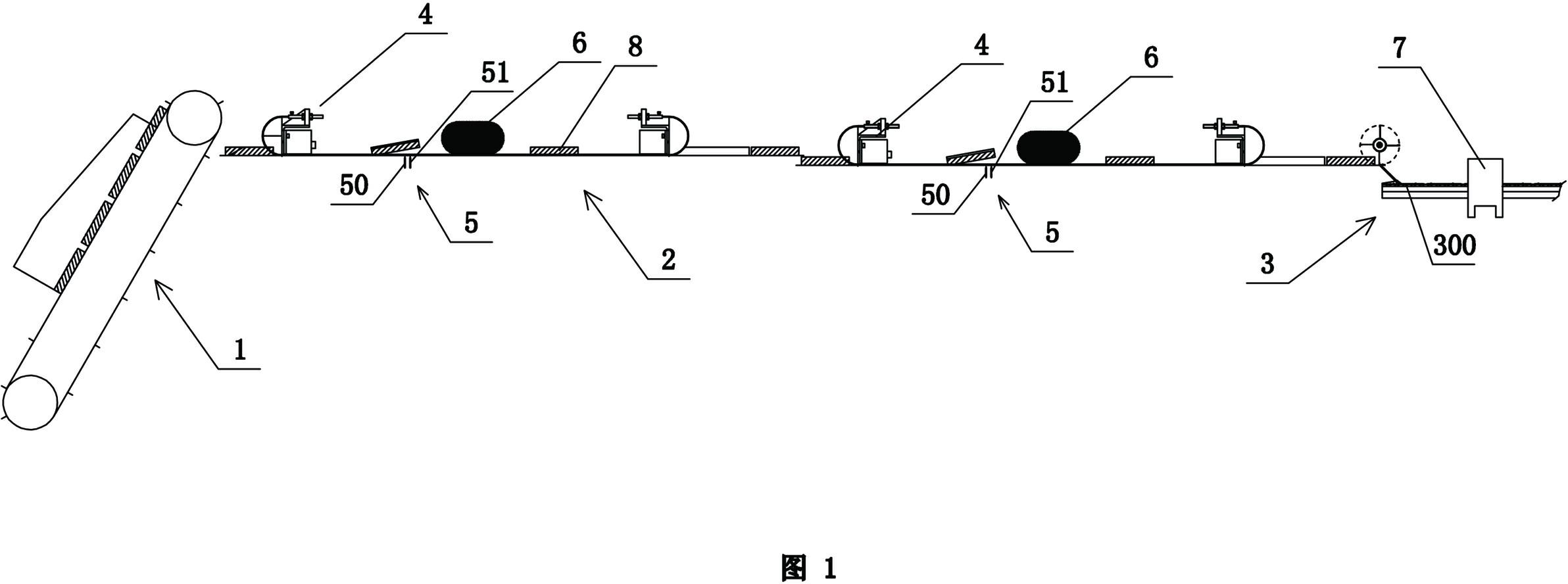

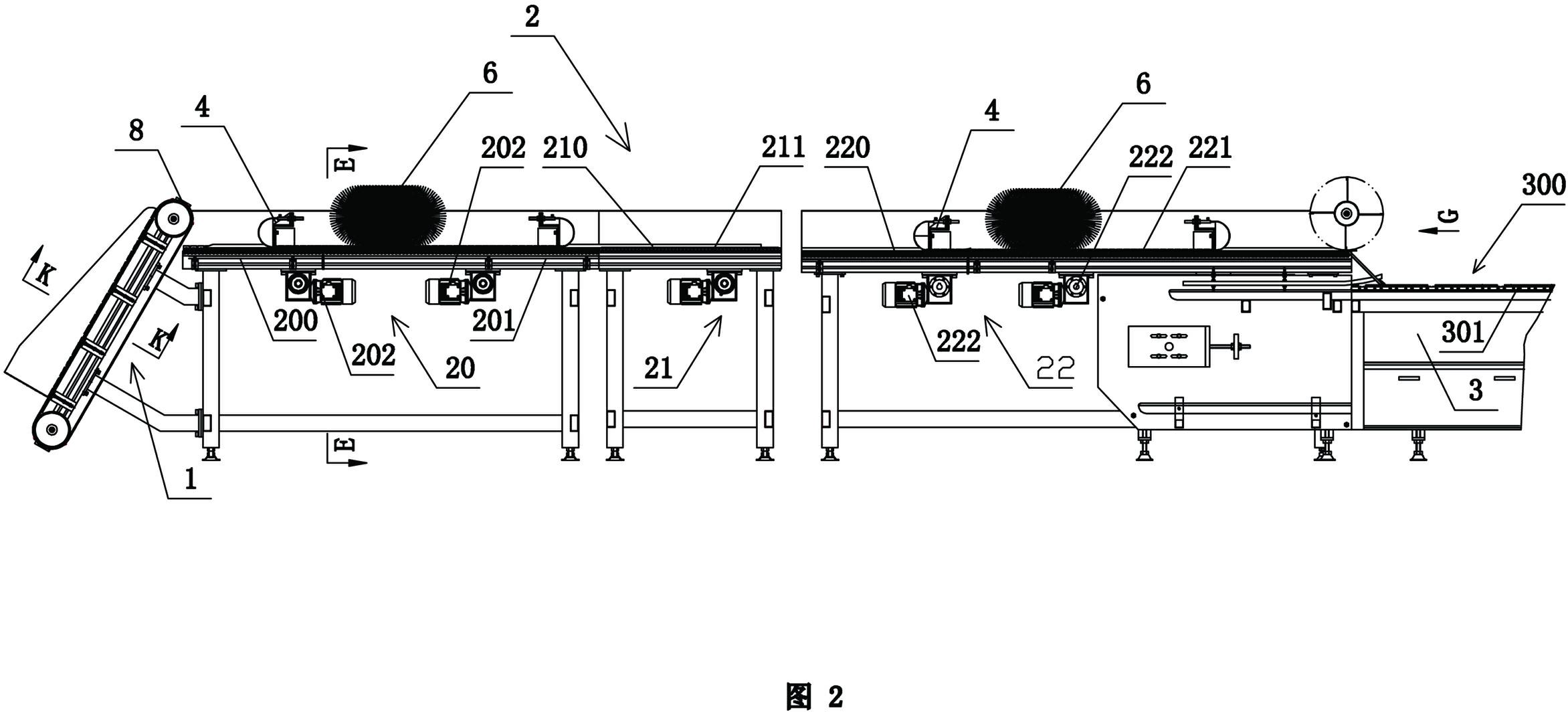

[0035] Refer to the attached figure 1 to attach Figure 14 Specific embodiments of the present invention will be described.

[0036] refer to figure 1 , figure 2 and image 3 . A new type of drying line for uniformly distributed array of small-sized ceramic tiles, including a lifting mechanism 1 for supplying ceramic tiles 8, a conveying mechanism 2 for transporting tiles 8, a horizontal array conveying mechanism 3, and a longitudinal array installed on the conveying mechanism 2 Mechanism 4, front and back identification and turning mechanism 5, brick sweeping mechanism 6, and a sticker machine 7 for pasting tile templates 300 covered with tiles 8 and a dryer for drying the tile template 300 after pasting ( not shown in the figure). The sticker machine 7 and dryer (not shown in the figure) are conventional existing equipment, and their structure and working principle will not be described again.

[0037] refer to figure 1 , figure 2 , image 3 , Figure 7 , Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com