Iron removal stirring machine

An iron stirring and agitator technology, which is applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of hindering stirring, lack of iron removal function, poor iron removal effect, etc., so as not to affect the effect of stirring and iron removal Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

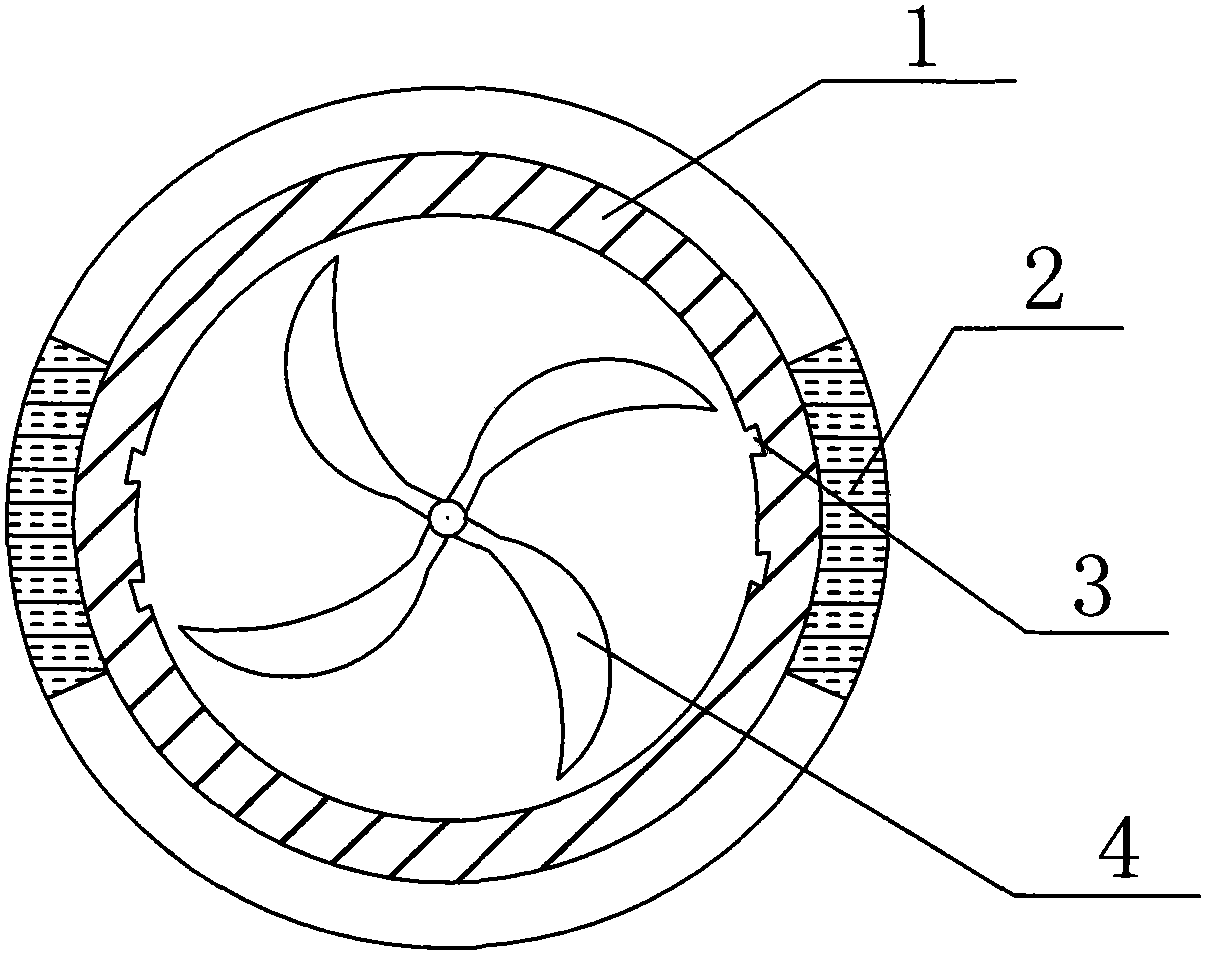

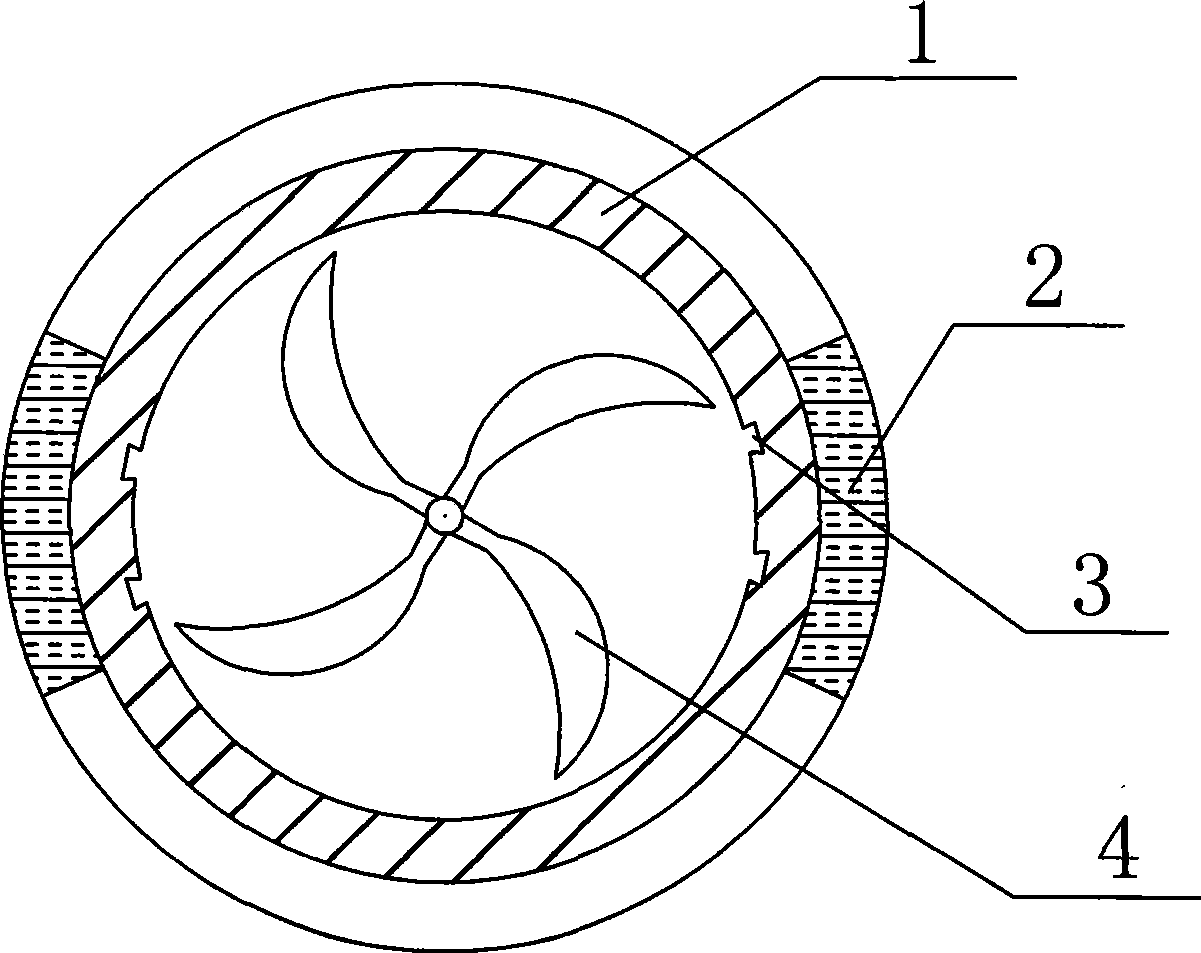

[0012] Such as figure 1 As shown, the iron removal agitator includes an agitator cylinder 1, which is characterized in that: the outside of the agitator cylinder 1 is provided with a magnet 2, and the inside of the agitator cylinder 1 is provided with a groove 3 near the magnetic pole.

[0013] This way, the iron is deposited in the grooves during the stirring process.

[0014] Further speaking, the groove 3 is perpendicular to the running direction of the stirring blade 4 .

[0015] In this way, the iron removal effect will be better.

[0016] Further speaking, the groove 3 is a square groove or a dovetail groove. In this way, the iron deposited in the groove is not easy to run out.

[0017] Further speaking, the depth of the groove 3 is 1-2 cm.

[0018] This will deposit less material and also achieve the purpose of depositing iron.

[0019] If the material con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com