Method for determining soot mass stored with a particulate filter

A particle filter and smoke particle technology, applied in the direction of machines/engines, electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, etc., can solve the problems of adding pressure sensors and increasing system costs, and achieve reduction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

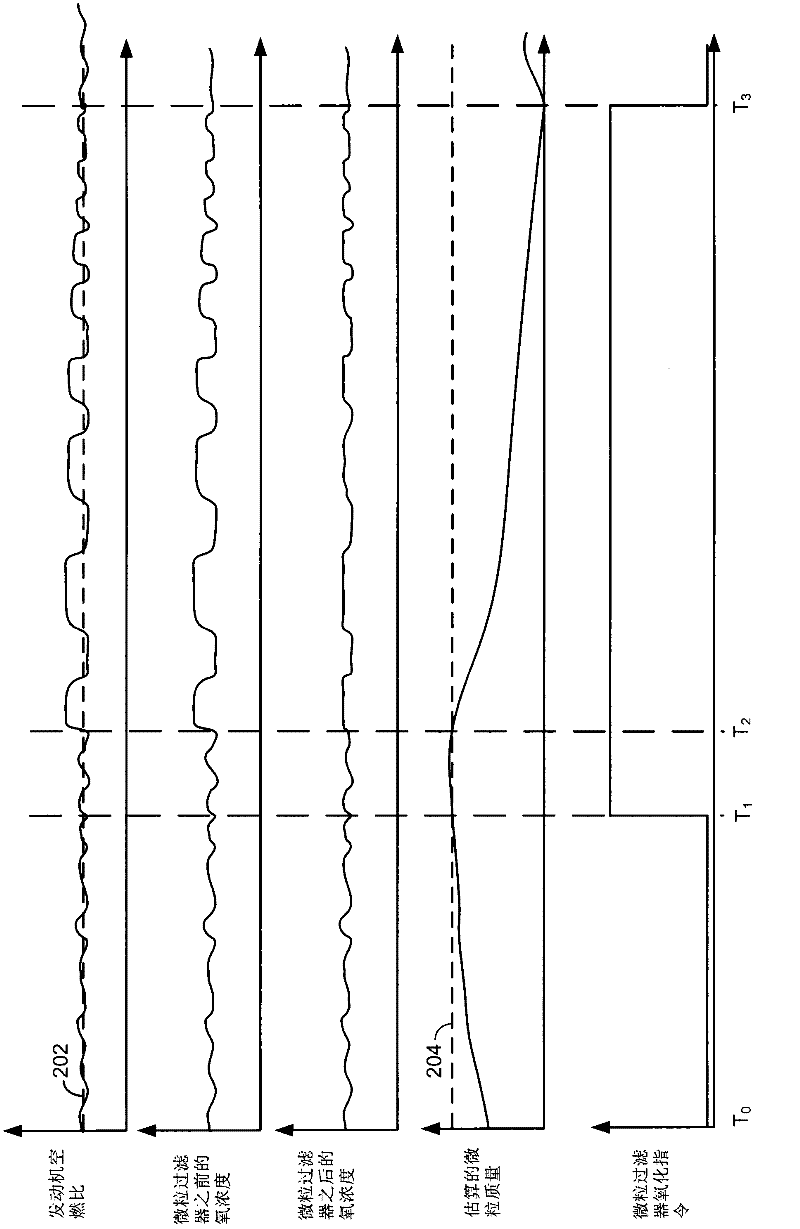

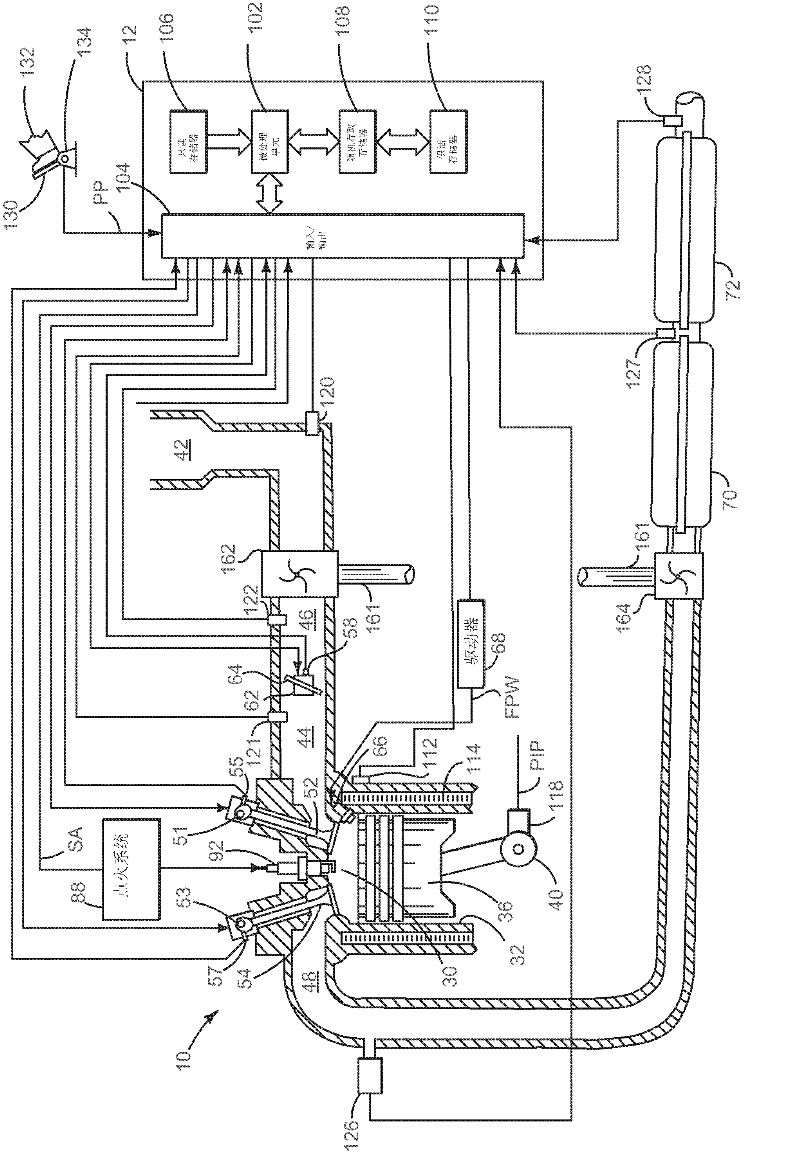

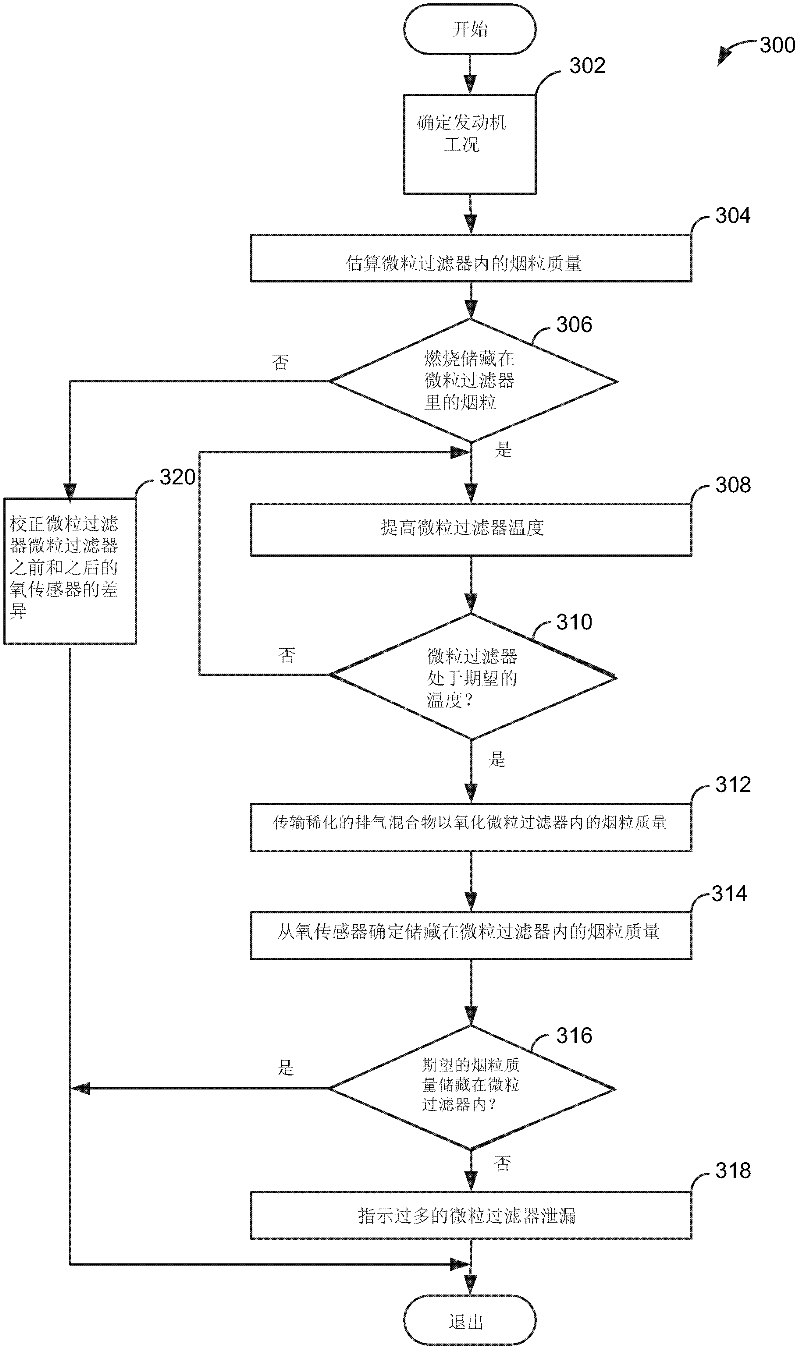

[0024] This description is directed to the determination of the mass of oxidized soot within a particulate filter. figure 1 One embodiment of a system including a particulate filter is shown. The system includes a spark ignition engine that can run on gasoline, alcohol, or a mixture of gasoline and alcohol. figure 2 The expected correlation signal for a system estimating soot mass from an oxygen sensor is shown. available by figure 1 system execution in Figure 3-5 The method in implements the signal.

[0025] refer to figure 1 , including multiple cylinders ( figure 1 An internal combustion engine 10 of which one cylinder is shown in ) is controlled by an electronic engine controller 12 . Engine 10 includes combustion chamber 30 and cylinder walls 32 with piston 36 positioned therein and connected to crankshaft 40 . Combustion chamber 30 is shown communicating with intake manifold 44 , exhaust manifold 48 via respective intake valve 52 , exhaust valve 54 . Each intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com