Storage battery system and storage battery module

A battery module and battery system technology, which is applied in the field of battery systems, can solve the problems of reduced charge and discharge capacity, performance decline, uneven charge and discharge capacitance, etc., and achieve the effect of safe replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

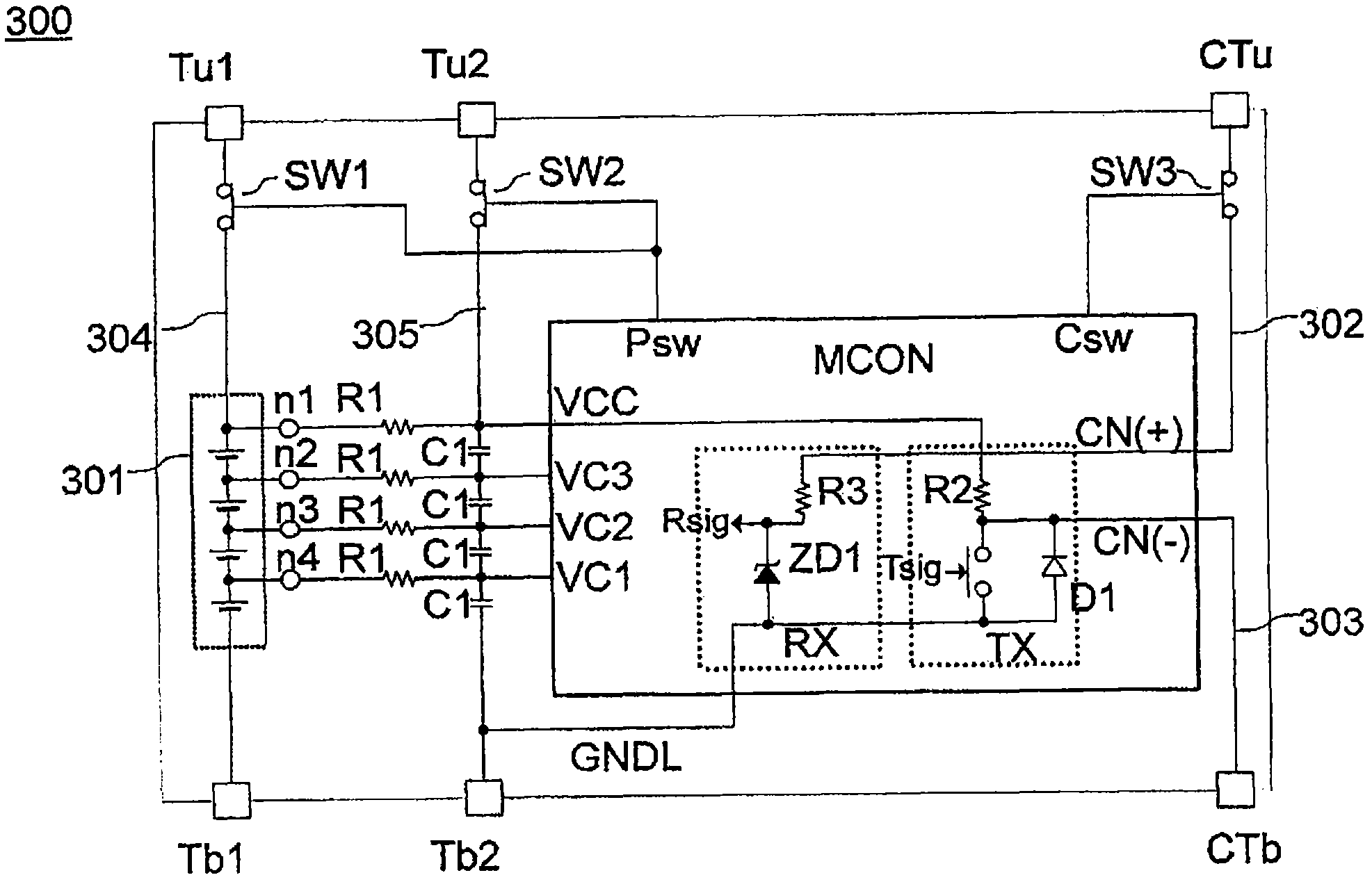

[0037] The first embodiment will be described. In the first embodiment, a battery system is constituted by a battery module incorporating a switch. image 3 is a block diagram showing the main configuration of the battery module 300 . as figure 1The battery module of the battery system is used. The storage battery module has a series-connected cell string 301 , a module controller MCON, and a switch SW for disconnecting the external terminals of the module from the internal elements. The cell array 301 is, for example, a secondary battery such as a lithium ion battery cell. The module controller MCON obtains the information of the voltage, current, temperature, etc. of the single battery, and communicates with the control device SCON through the communication line 302 and the communication line 303 connected in series with other modules. In this example, a transmission circuit TX and a reception circuit RX for unidirectional communication with the control device SCON are s...

Embodiment 2

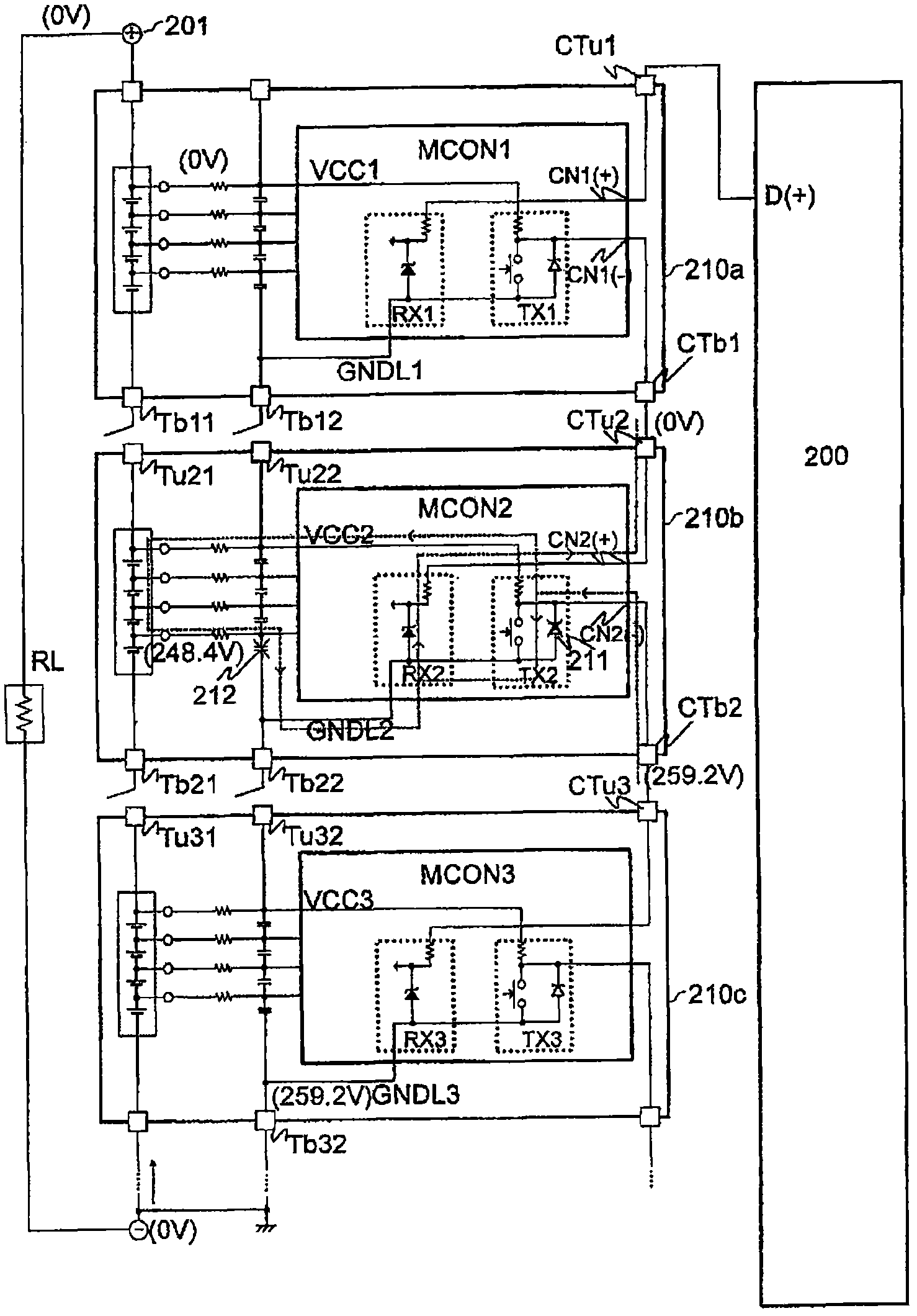

[0052] The second embodiment will be described. In the second embodiment, insulation breakdown of the internal elements of the module is prevented by making the structure of the external terminals of the storage battery module different in the power supply terminal and the communication terminal. In the second embodiment, the internal structure of the battery module is equivalent to figure 2 The structure of 210.

[0053] Figure 9 , Figure 10 The external appearance and cross-sectional view of the battery module 900 according to the second embodiment are respectively shown. A communication connector 901 and power supply connectors (positive and negative poles) 903 and 904 are provided on the back portion of the battery module case 905 . If it is a module supporting bidirectional communication, four communication connectors 901 are provided. Such as Figure 10 As shown, the front end of the communication connector 901 is shorter than the front ends of the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com