Electrode space control system for insulating gas discharge decomposition component detection device

A technology for insulating gas and decomposing components, which is applied in the direction of electrical program control, digital control, and testing of dielectric strength. The effect of ensuring the service life and accurate positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

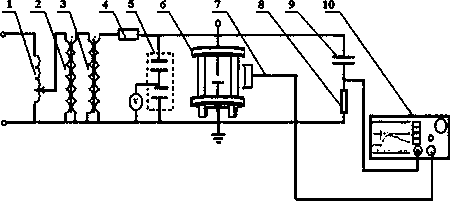

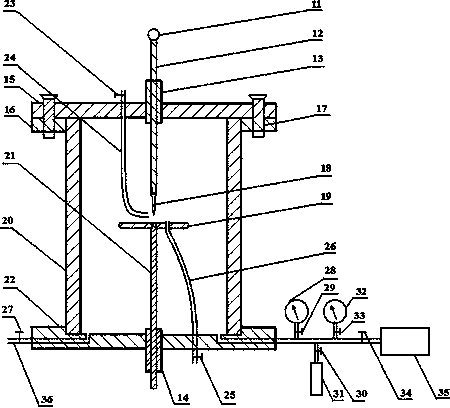

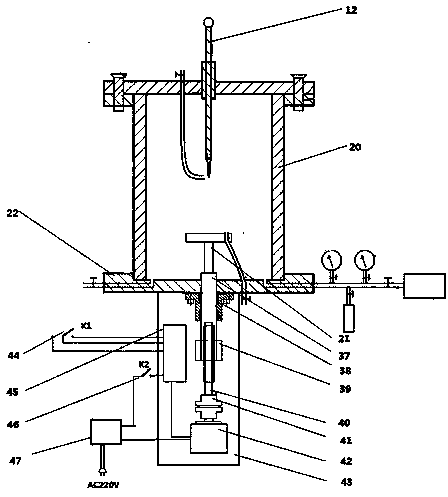

[0029] Such as Figure 1~3 As shown, a control system for the electrode spacing in the insulation gas discharge decomposition component detection system is that the low-voltage conductive rod in the insulation gas discharge decomposition device in the existing insulation gas partial discharge decomposition component detection system protrudes from the shell On one end of the body, an adjustment system for electrode spacing is added. The electrode spacing adjustment system consists of an insulating bushing 37, a sealing buckle sleeve 38, a linear guide rail 39, a ball screw 40, a coupling 41, a servo motor 42, a back plate 43, a single-pole single-throw switch 44, a servo driver 45, Single-pole double-throw switch 46, 24V DC power supply 47 and other components.

[0030] The insulating bushing 37 is a polytetrafluoroethylene bushing with an outer diameter of 20 mm and a length of 105 mm. At the axial center of the insulating bushing 37, a diameter matching the outer diameter o...

Embodiment 2

[0039] A multi-region detection system for partial discharge decomposition components of insulating gas is the same as that in Embodiment 1. Wherein the insulating bushing 37 is a polytetrafluoroethylene bushing with an outer diameter of 25mm and a length of 115mm, the outer diameter of the upper disk of the sealing buckle sleeve is 75mm, and the thickness is 15mm, and the outer diameter of the lower cylinder is 50mm, The height is 50mm, the back plate is 550mm in length, 150mm in width, and 25mm in thickness, and the linear guide rail 39 is 65mm away from the lower end surface of the lower fixing plate 22 of the insulating gas discharge decomposition component detection device. The precision of the ball screw is between C4 and the diameter of the screw is 15mm.

Embodiment 3

[0041] A multi-region detection system for partial discharge decomposition components of insulating gas is the same as that in Embodiment 1. Wherein the insulating bushing 37 is a polytetrafluoroethylene bushing with an outer diameter of 30mm and a length of 125mm, the outer diameter of the upper disk of the sealing buckle sleeve is 80mm, and the thickness is 20mm, and the outer diameter of the lower cylinder is 60mm, The height is 60mm, the back plate is 580mm in length, 160mm in width, and 30mm in thickness, and the linear guide rail 39 is 70mm away from the lower end surface of the lower fixing plate 22 of the insulating gas discharge decomposition component detection device. The accuracy of the ball screw is between C3 and the diameter of the screw is 20mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com