Movable automatic horizontal positioning detection arm for tunnel

A horizontal positioning and mobile technology, which is applied in the direction of measuring devices, material analysis using microwave means, instruments, etc., can solve the problem of undetected detection arms, etc., and achieve the effect of relieving labor intensity, improving efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

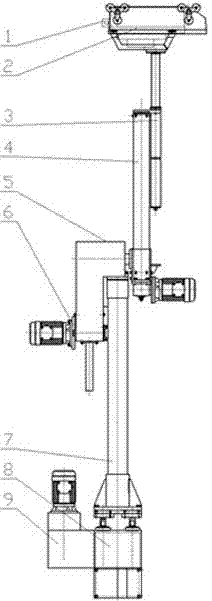

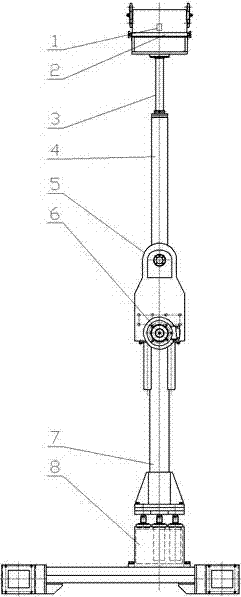

[0041] 1. The geometric dimensions of the automatic horizontal positioning detection arm of the tunnel of the present invention (unit: mm):

[0042] Maximum dimensions: width X thickness X height 1500X1000X5600.

[0043] The maximum measuring radius is 3000.

[0044] The maximum bearing capacity is 50kg.

[0045] Minimum size after shrinking: width X thickness X height 1500X1000X1500.

[0046] 2. Protection frame:

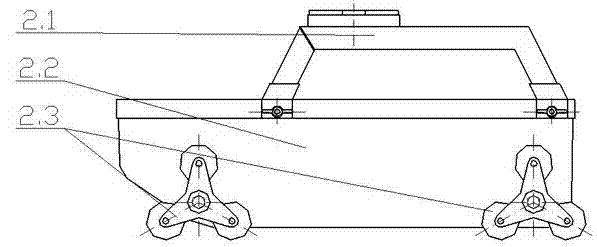

[0047] The size of the protective frame varies according to the specifications of the testing instrument. The geometric dimensions of the protective frame are made according to the geometric dimensions of the testing instrument. image 3 and Figure 4 As shown, the triangle wheel is composed of 3 polyurethane wheels with an outer diameter of 60, a total of 4 groups such as image 3 and Figure 4 Shown.

[0048] 3. Damping arm:

[0049] The moving rod (3.1) is a 50X50X2 stainless steel square tube with a length of 430, and a 100X60X5 steel plate with a 35X35 thickness 5 position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com