Durability testing method for rotary vehicle door system and durability testing device

A durable test, rotary technology, applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problem of not being able to effectively detect the matching performance of the reliability-related functional parts of the door system, and the performance assessment of no matching functional parts. , the test method is not clear and other problems, to achieve high reliability, easy operation, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

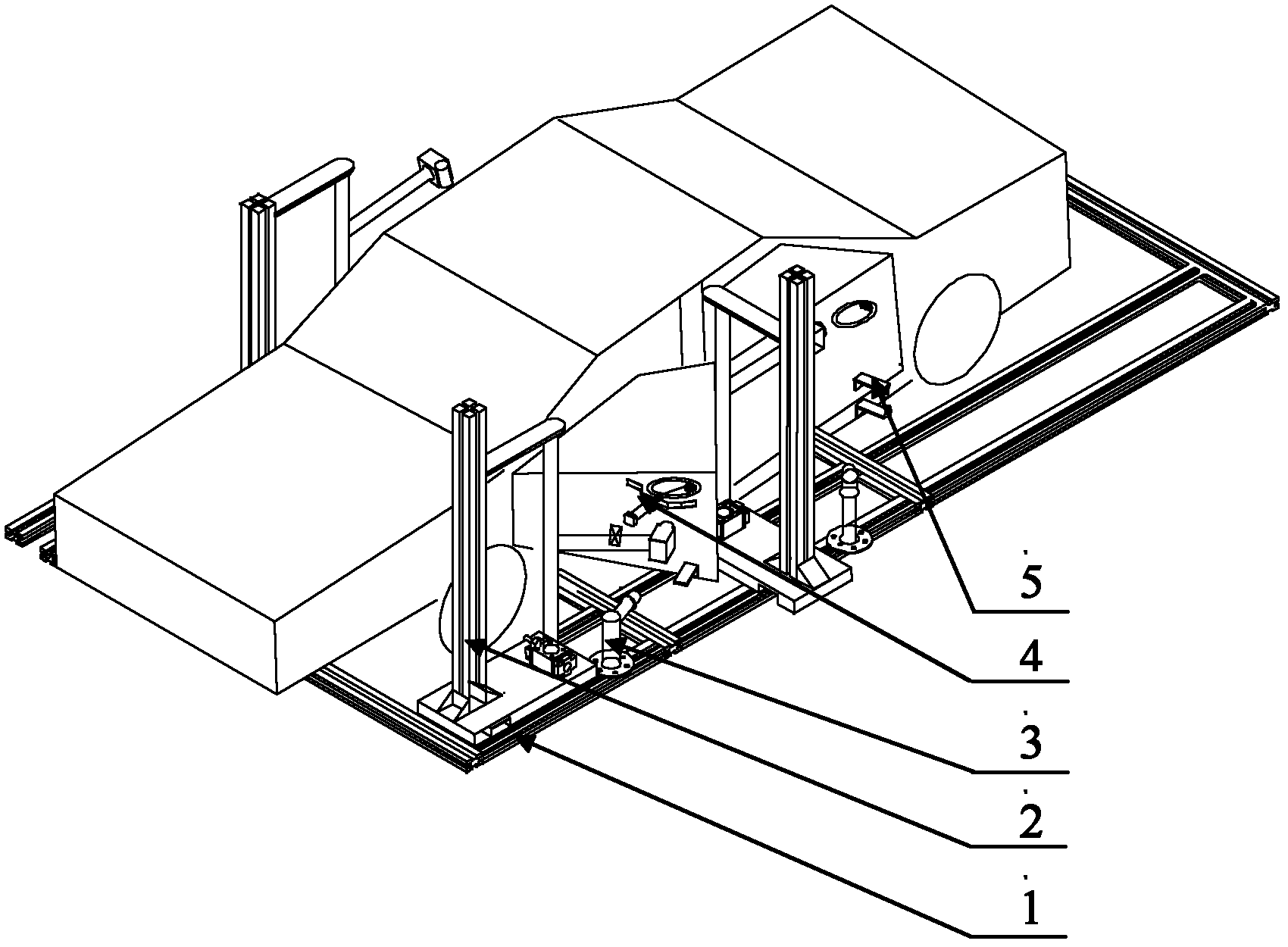

[0055] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

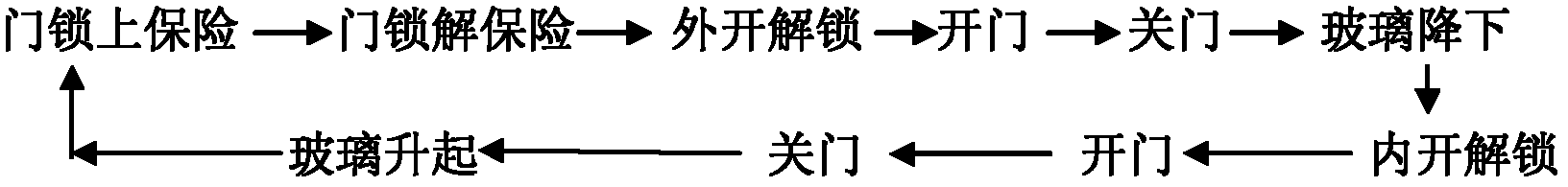

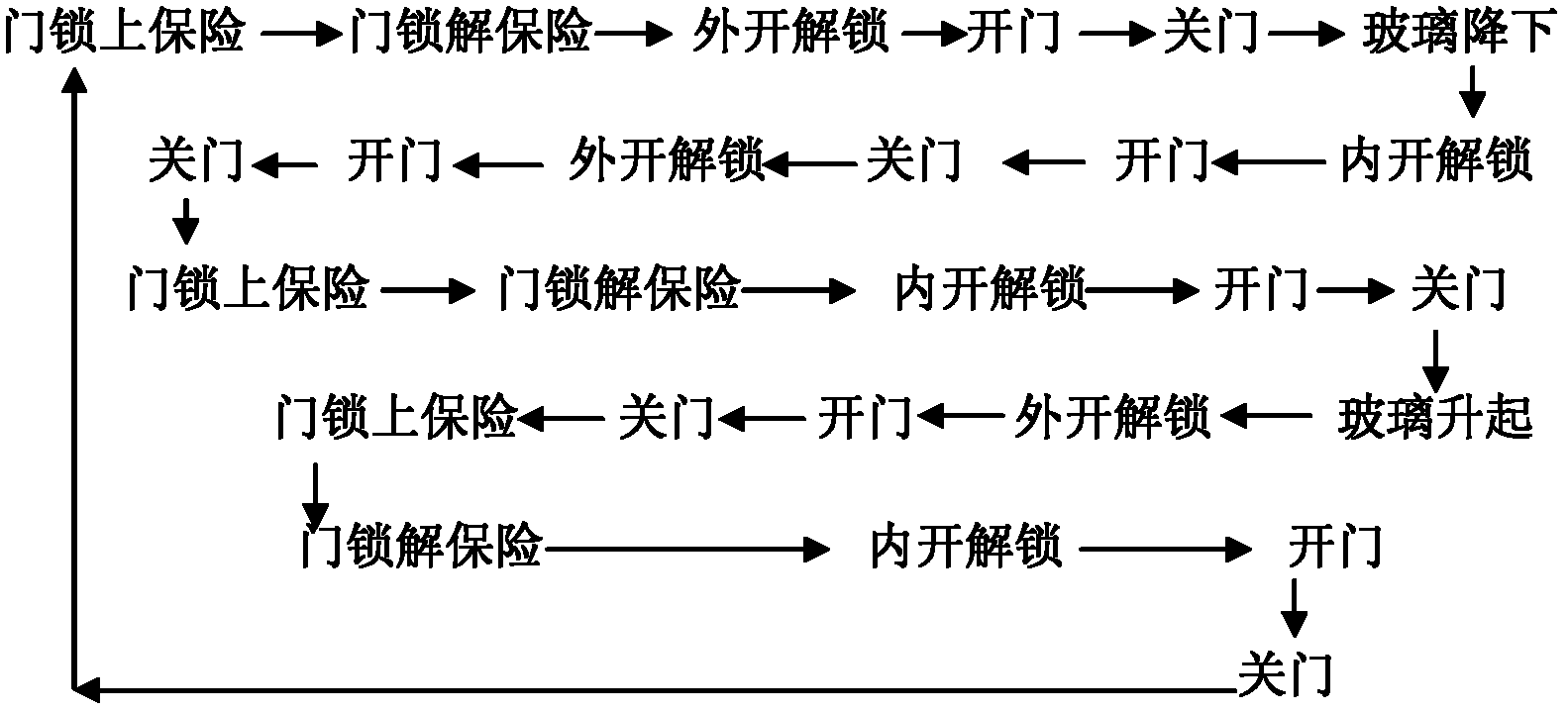

[0056] Since the door system includes door sheet metal assembly, electric door lock assembly, door hinge, limiter, inner handle, outer handle, glass regulator, sealing strip and other related functional components, the test method is set as follows:

[0057] Step 1: After the door is closed, activate the door lock insurance;

[0058] Step 2, activate the door lock and unlock the insurance;

[0059] The door locking insurance in the step 1 and the door unlocking insurance in the step 2 specifically include the following two types:

[0060] When the door is opened inside, perform the action of locking and unlocking the electric door lock in sequence, and then start the unlocking of the inside opening door in step 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com