Device for nesting inner tank body and outer tank body of cryogenic liquid transportation semitrailer

A low-temperature liquid and outer tank technology, which is applied to oil tankers and other directions, can solve problems such as the difficulty of fitting the inner and outer tanks, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

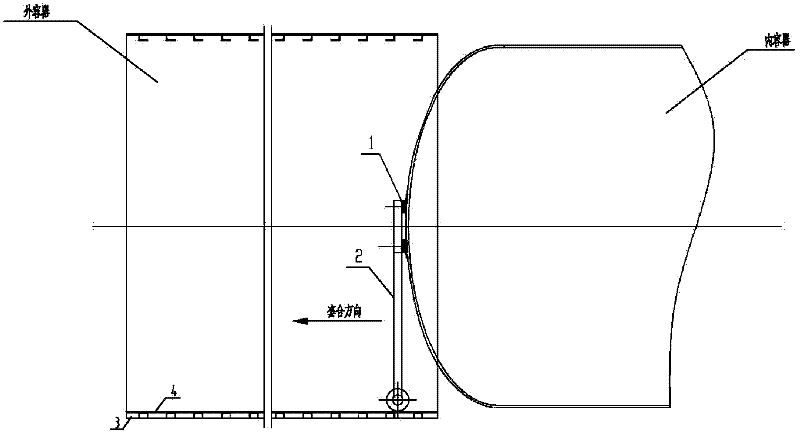

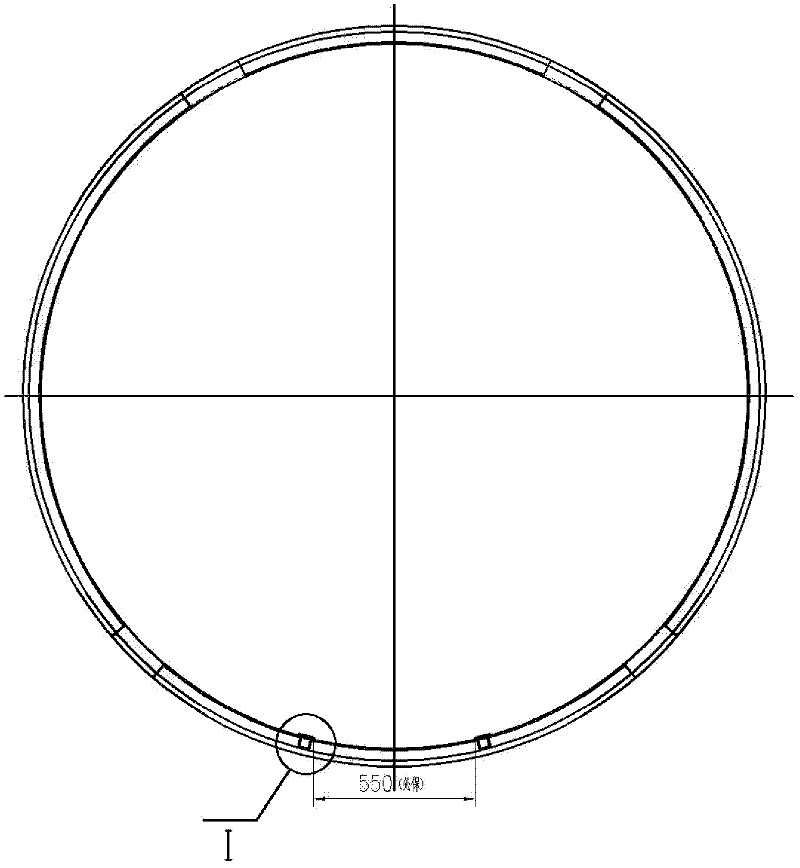

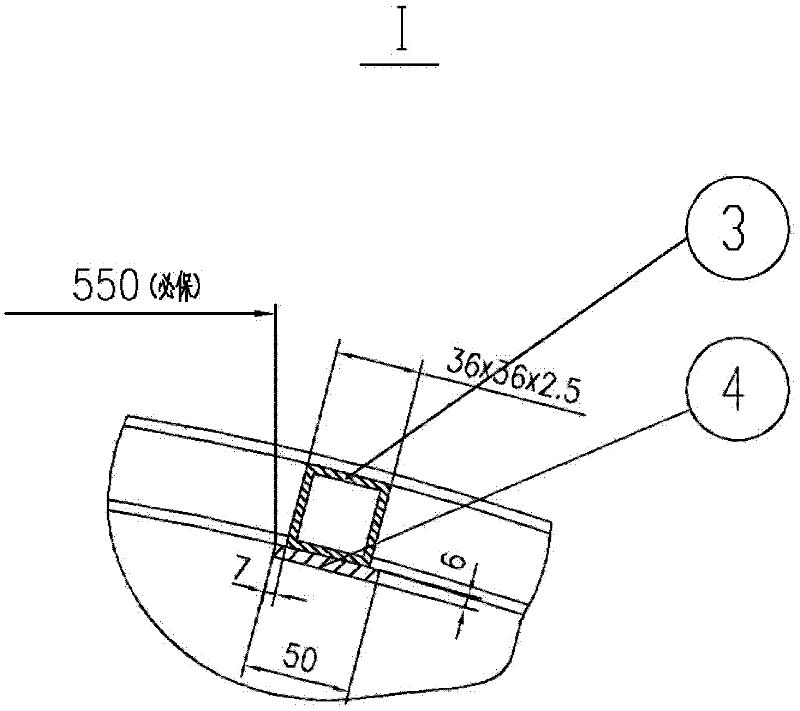

[0015] The invention includes winding flanges, square steel pipes, flat steel and assembly trolleys. The winding flange 1 is respectively assembled (welded) to the heads at both ends of the inner tank, the axis of the winding flange 1 coincides with the axis of the inner tank (the winding flange can also be used as a wrapping tool for the inner tank insulation paper), and the assembly trolley 2 and the winding flange 1 are threaded to support the inner tank body, and the assembly trolley 2 along the track formed by the square steel pipe 3 and the flat steel 4 smoothly loads the inner tank body into the outer tank body under the action of external power, realizing the internal and external Fitting of tanks. After the fitting is completed, the assembly trolley can be disassembled for repeated use.

[0016] DN160 stainless steel winding flange, steel structure assembly trolley, 36×36×2.5 square steel pipe and 50×6 flat steel form the assembly track. The winding flanges are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com