Horizontal type bending machine used for forming annular piece

A technology of bending machine and ring parts, applied in the field of equipment for forming large metal ring parts, can solve the problems of blank feeding, inability to form large ring parts, difficult forming operations, etc. Even wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

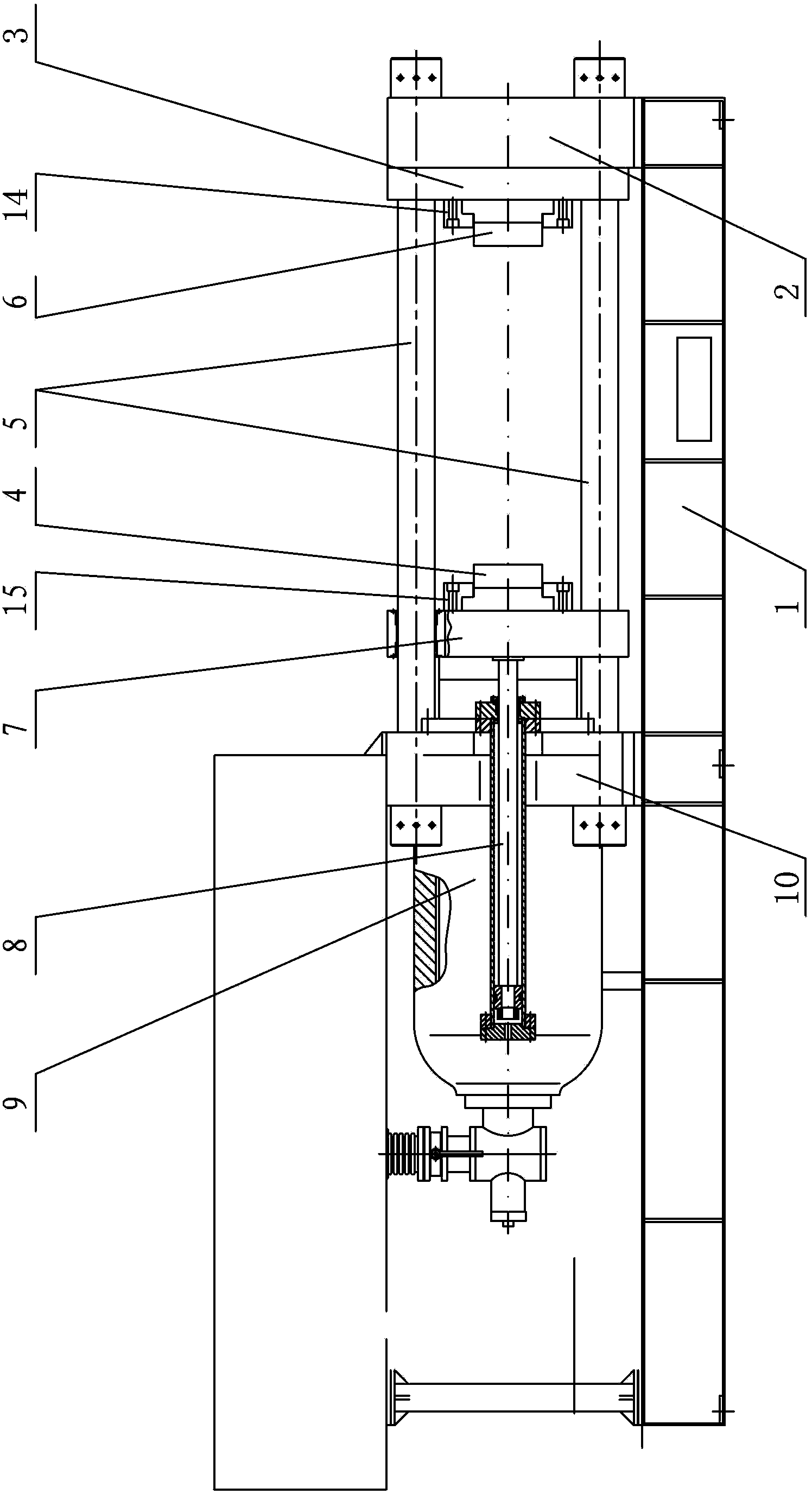

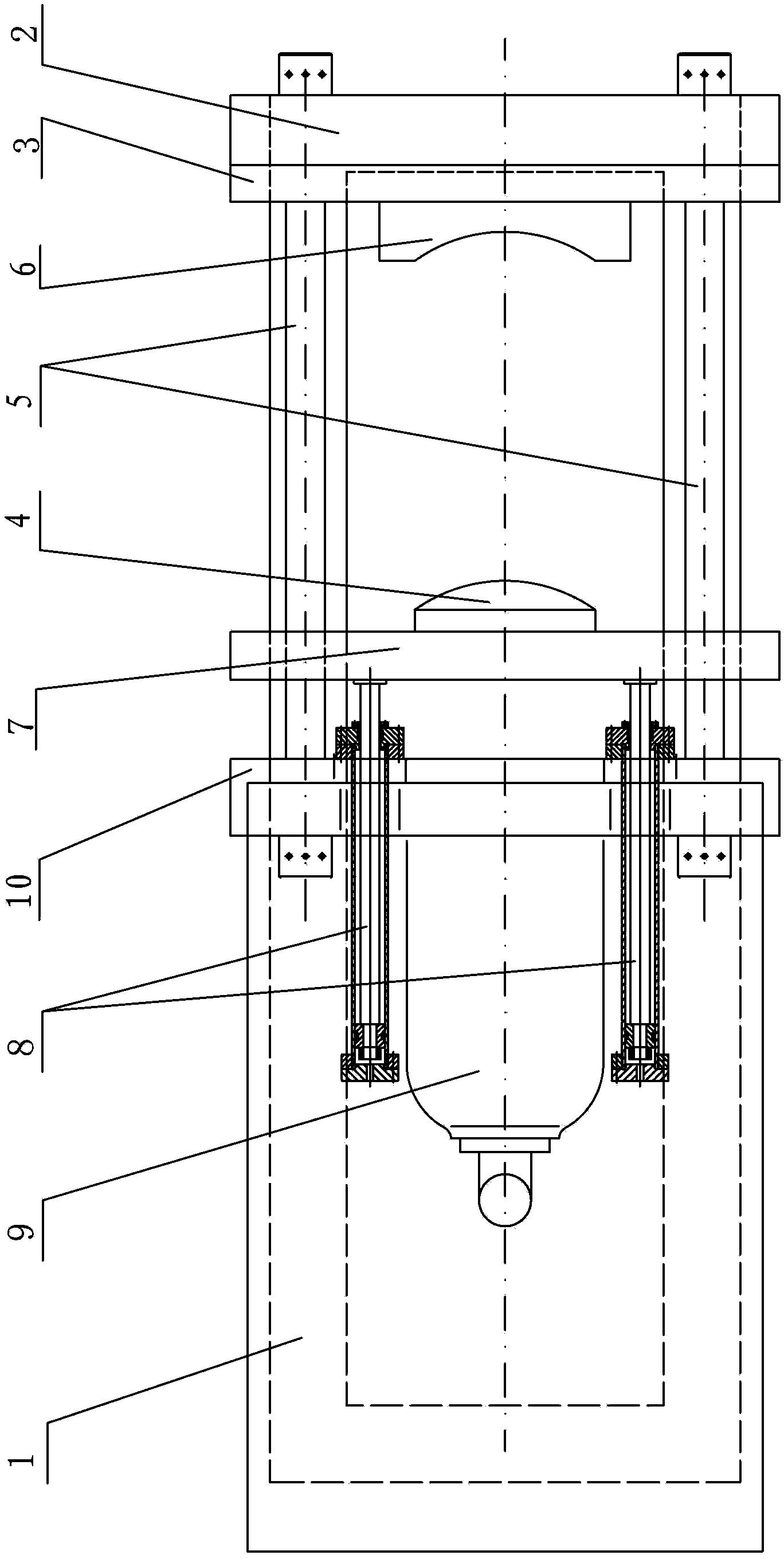

[0010] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a horizontal bending machine for ring forming in this embodiment includes a frame 1, a first beam 2, a second beam 10, a working platform 3, a die 6, a punch 4, and a movable platform 7. The main hydraulic driving device 9, two side hydraulic driving devices 8 and four horizontal columns 5, the working platform 3, the first beam 2, the second beam 10 and the main hydraulic driving device 9 are horizontally installed on the upper surface of the frame 1 Above, the first crossbeam 2 and the second crossbeam 10 are arranged side by side along the length direction of the frame 1, the first crossbeam 2 and the second crossbeam 10 are provided with four horizontal columns 5 along the length direction of the frame 1, and the movable platform 7 The working platform 3 is located between the first beam 2 and the second beam 10, four horizontal columns 5 are pierced with a movable platform 7...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the bending machine described in this embodiment further includes a first press plate 15 , and the punch 4 is connected to the movable platform 7 through the first press plate 15 provided on the punch 4 . With such arrangement, the connection is firm and stable, which is convenient for fixing the punch. Meet the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the bending machine described in this embodiment further includes a second press plate 14 , and the die 6 is connected to the working platform 3 through the second press plate 14 provided on the die 6 . With such arrangement, the connection is firm and stable, which is convenient for fixing the die. Meet the design requirements and actual needs. Others are the same as in the first or second embodiment.

[0014] work process

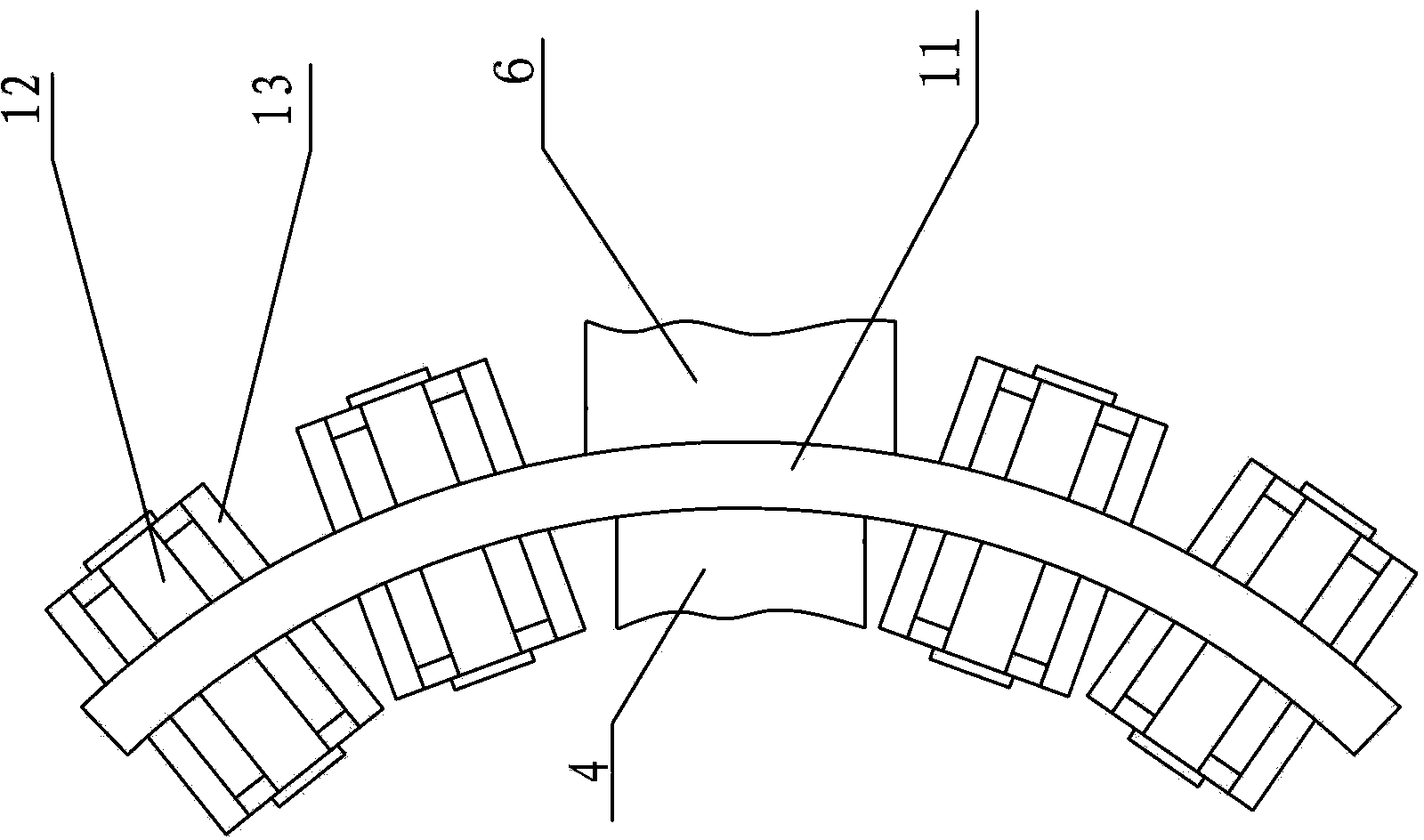

[0015] combine Figure 1-Figure 5 To illustrate the working process of the present invention, when the ring is pressed and formed, the blank 11 is horizontally placed between the punch 4 and the die 6, and the blank 11 is placed on the cylindrical rolling body 12 arranged on the bracket 13 of the movable support frame , the number and placement angle of the movable support frame can be adjusted and placed according to the size and bending radius of the bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com