Seamlessly-spliced display screen

A technology of seamless splicing and display screen, which is applied in the direction of instruments, identification devices, etc., can solve the problems of high cost, damage to image continuity and integrity, and inability to realize seamless splicing display, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

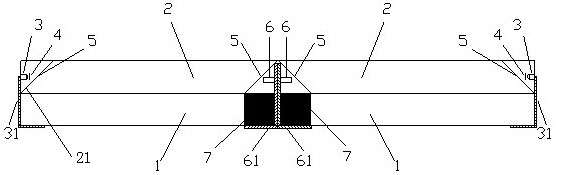

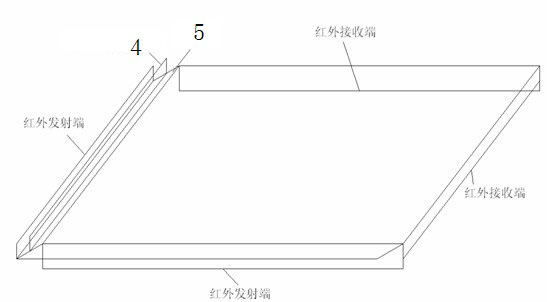

[0025] Such as figure 1 with figure 2 Shown is a schematic diagram of the structure of the present invention. A seamless splicing display screen, comprising mutually spliced display screens 1, a first linear polarizer is attached to the surface of each display screen 1, a rhomboid prism 2 is installed on the surface of the first linear polarizer, and the rhomboid prism 2 Both the surface and the back are flat and parallel to each other; the sides on the same side of the patchwork 7 formed by splicing the display screen 1 on the rhombic prism 2 and the side opposite to the side are set as mutually parallel parallel slopes 21, on the parallel slopes 21 All are coated with a prism polarizing beam splitting film 5, and the parallel slope 21 far away from the seam 7 uses the prism polarizing beam splitting film 5 to reflect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com