Determination method for heat source model parameters in multiplewire submerged-arc welding by numerical simulation

A technology of multi-wire submerged arc welding and heat source model, which is applied in arc welding equipment, electrical digital data processing, welding equipment and other directions, and can solve problems such as difficulty in determining heat source parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

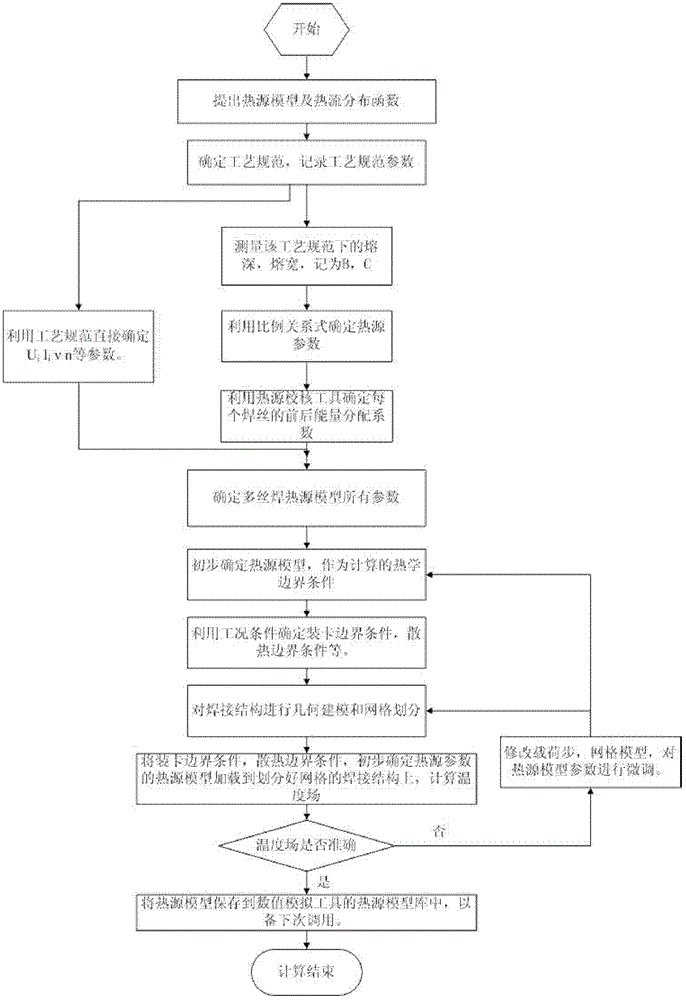

Method used

Image

Examples

Embodiment

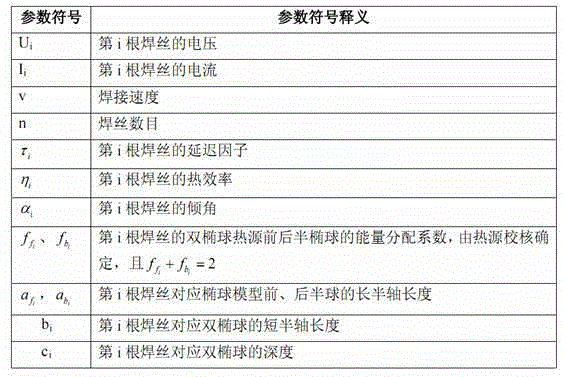

[0035] Step 1: Determine the parameter U of the heat source model i , I i , V, n, α i , Τ i , Η i

[0036] Welding specification parameter table

[0037]

[0038] Directly determined by welding specification U i , I i , V, n, α i , Τ i By formula S i / v is calculated, where S i Is the distance between i wire and 1 wire, considering the influence of working conditions, η i For the thermal efficiency of submerged arc welding, 0.9 is taken in this embodiment.

[0039] The heat flux density at position (x, y, z) at time t is:

[0040] q ( x , y , z , t ) = X i = 1 4 6 3 f f i , bi η i U i I i a ( f i , b i ) b i c i π π exp { - 3 [ ( x 2 b i 2 ) + ( ( y + v ( τ i - t ) 2 ( a ( f i , b i ) cos α i ) 2 ) + ( z 2 ( c i cos ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com