Automatic sample feeding tray for temperature-controllable type microreactor with magnetic stirring function

A technology of magnetic stirring and micro-reactor, applied in the direction of instruments, analytical materials, etc., can solve the problems of non-seamless connection, low degree of tray integration, and inability to take advantage of automatic sampling, so as to solve the problem of uneven stirring and integrated high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The automatic sampling tray of the present invention with a temperature-controllable microreactor with magnetic stirring function will be described in detail below in conjunction with the embodiments and accompanying drawings.

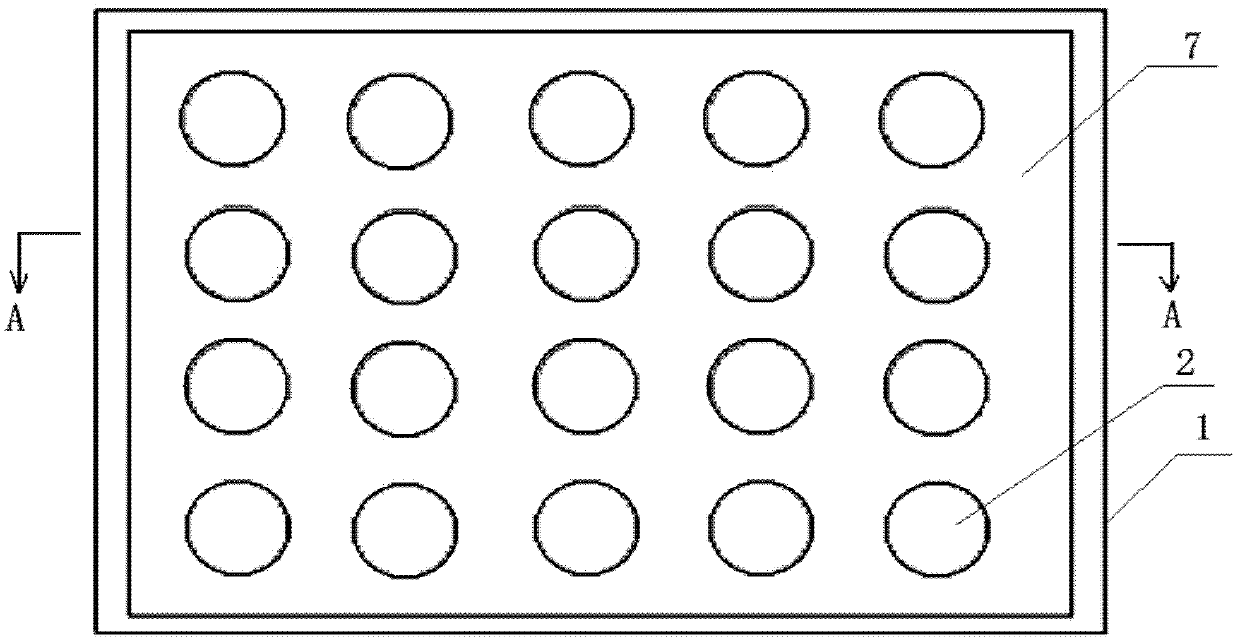

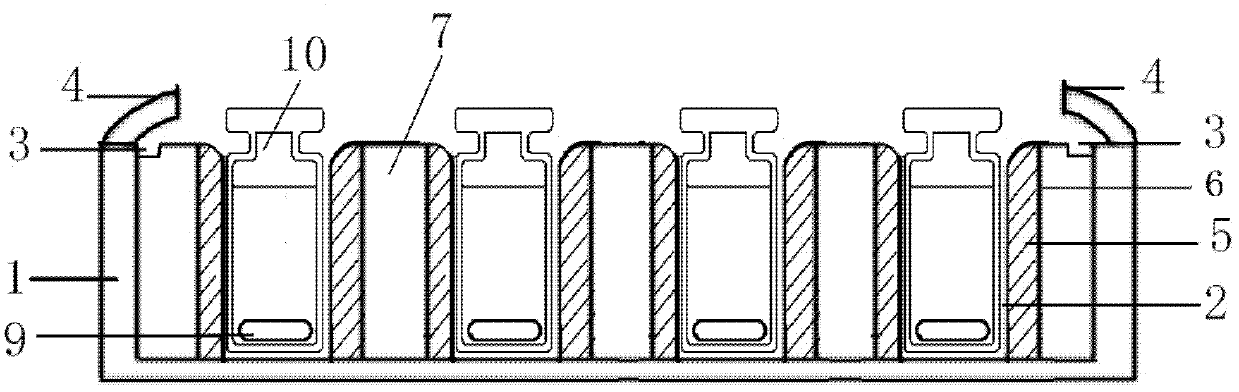

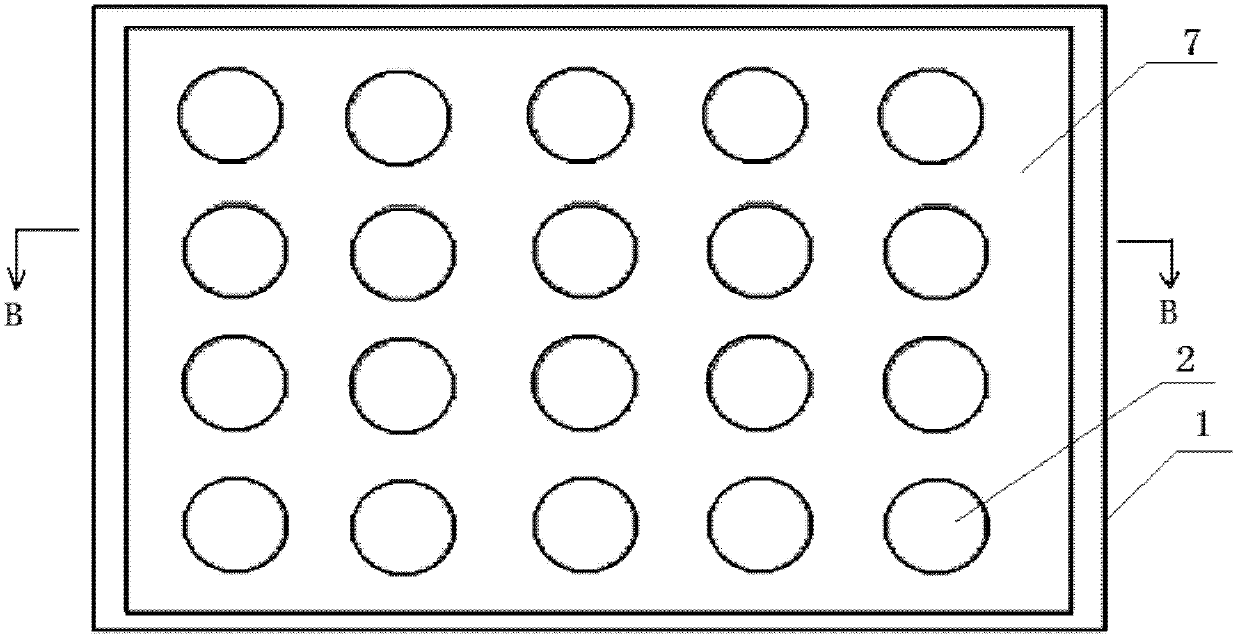

[0036] Such as figure 1 , figure 2 As shown, the auto-sampling tray of the present invention with a temperature-controllable microreactor with magnetic stirring function includes a tray 1, and a middle water bath chamber 7 is arranged in the tray 1, and the middle water bath chamber 7 is provided with a heating wire electrically connected to the external circuit of the tray 1 and a plurality of temperature-sensing chips. A plurality of sample vial slots 2 for placing sample vials 10 are inserted into the middle water bath chamber 7, and the outer peripheral surface of the sample vial slots 2 is provided with a circuit electrically connected to the outside of the tray 1. The four-phase stepping coil 5 is provided with a shielding layer 6 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com