Method for detecting leveling property of battery slurry

A detection method and leveling technology, applied in flow characteristics, measuring devices, analysis materials, etc., can solve problems such as large errors and inability to detect clearly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Take two types of slurry of the same system, numbered as slurry A and slurry B, and test them in the following ways:

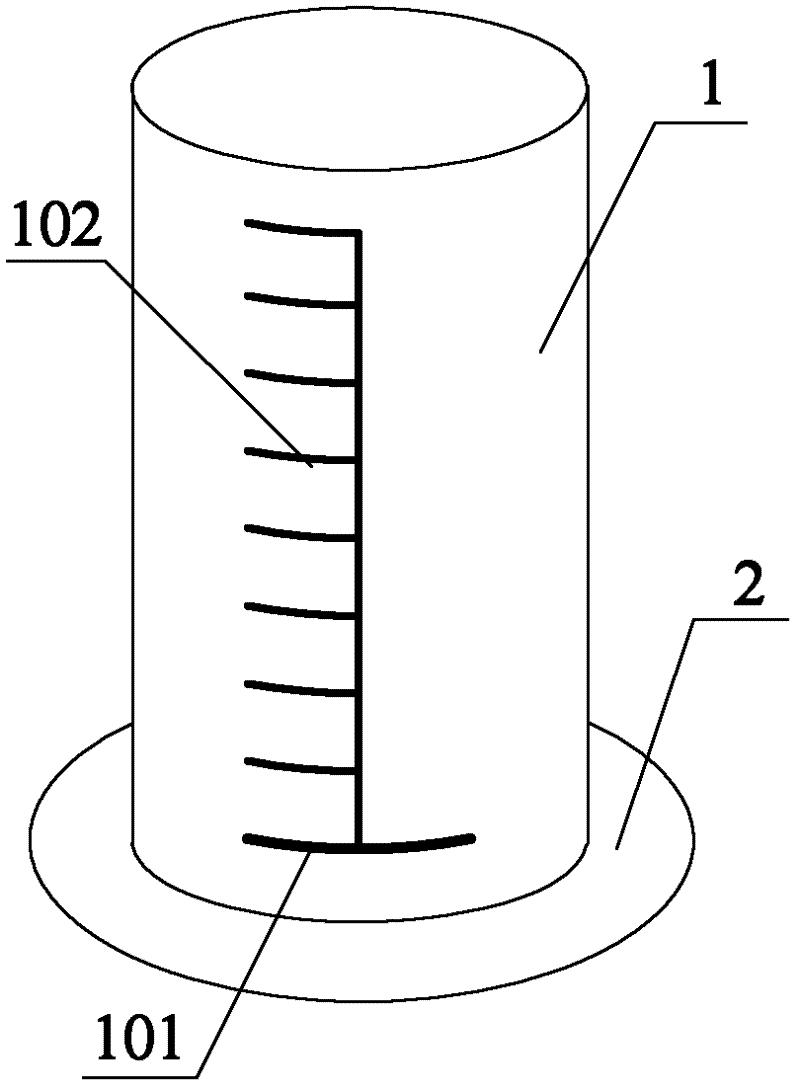

[0052] 1. Place the pre-cleaned and dried container on the horizontal platform. Take the slurry to be tested and pour the electrode slurry into the solution. The operator's eyes are level with the marked line at the bottom of the container, and ensure that the slurry plane is just level with the marked line. During the process of pouring the slurry, it is necessary to ensure that the slurry does not touch the container. On the side wall above the marked line, otherwise the container needs to be washed and dried and then the above steps are repeated.

[0053] 2. Tilt the container slowly until the mouth of the container touches the horizontal surface, fix the position of the container, start timing at the same time, and set the standing time to 1min.

[0054] 3. After 1 minute, put the container on the horizontal surface stably, and read the number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com