Deformation monitoring method for existing railway line

A deformation monitoring and existing line technology, which is applied in the field of deformation monitoring of existing railway lines, can solve the problems affecting the operation of existing lines, the large size of monitoring components, and unsatisfactory conditions, so as to ensure the safe operation of trains, ensure personal safety, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0023] A method for monitoring deformation of existing railway lines, comprising the following steps:

[0024] (1). Select the appropriate type of total station (total station electronic speed measuring instrument) and prism.

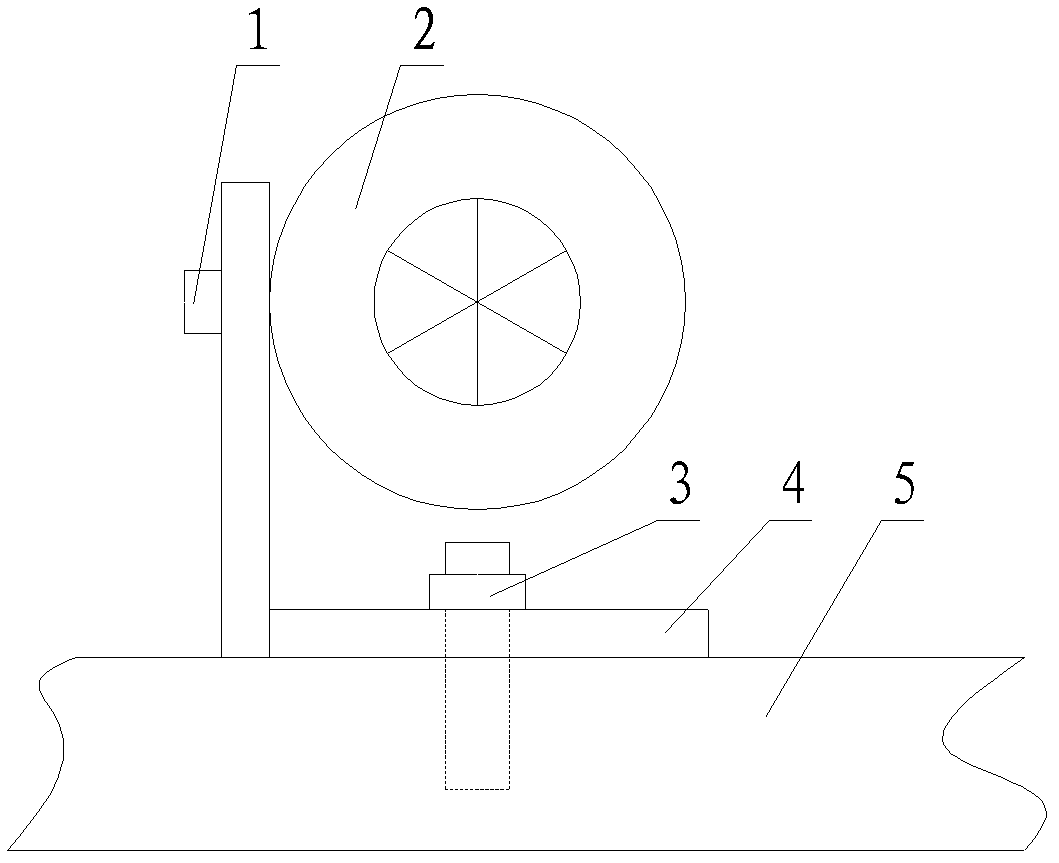

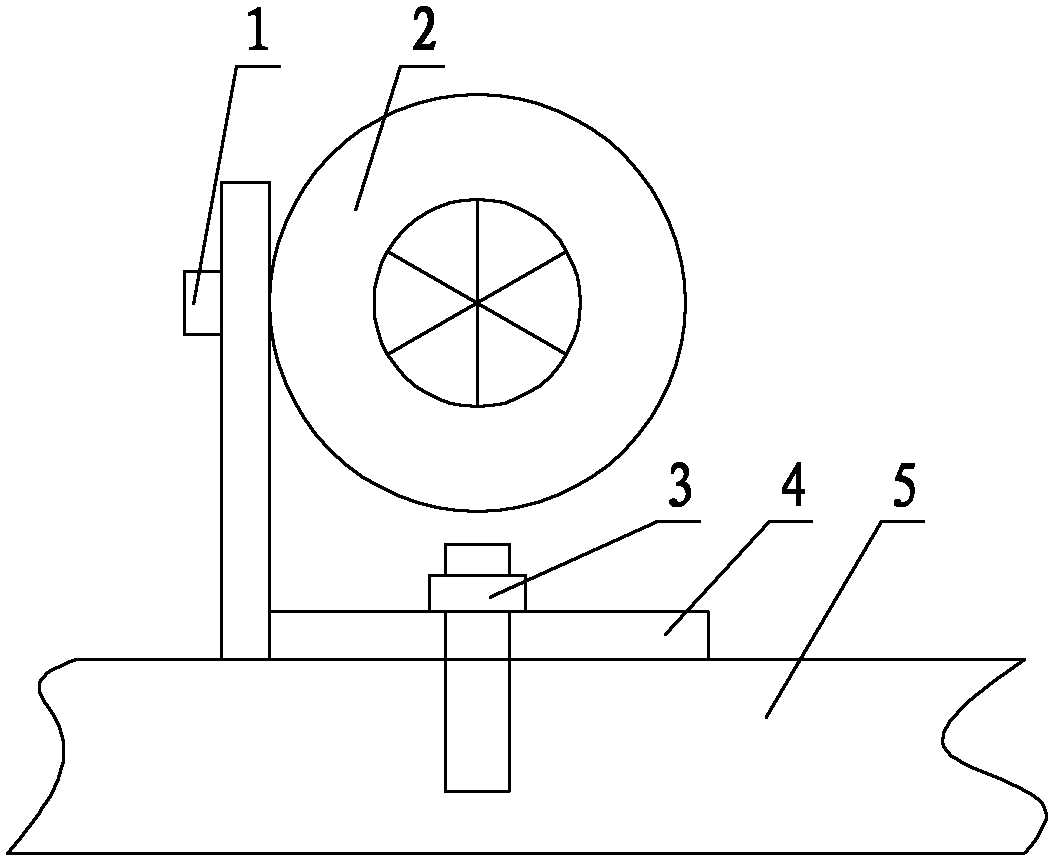

[0025] This prism comprises small prism body 2 and an L-shaped support frame 4, and this L-shaped support frame is made of vertical vertical plate and horizontal base plate, and small prism body is installed on the upper end of vertical vertical plate by screw 1, is made on the horizontal base plate Make one or two vertical mounting holes.

[0026] (2). Arrange points for the lines to be measured, and install a prism on each measurement point.

[0027] The specific method is as follows: first drill a hole on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com