Hydrocone type multi-stage hydroelectric generation method

A technology of siphon type and siphon pipes, which is applied in hydropower, engine components, machines/engines, etc., can solve the problems of large geographical restrictions and high project cost, and achieve the effect of low project cost, small geographical restrictions and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

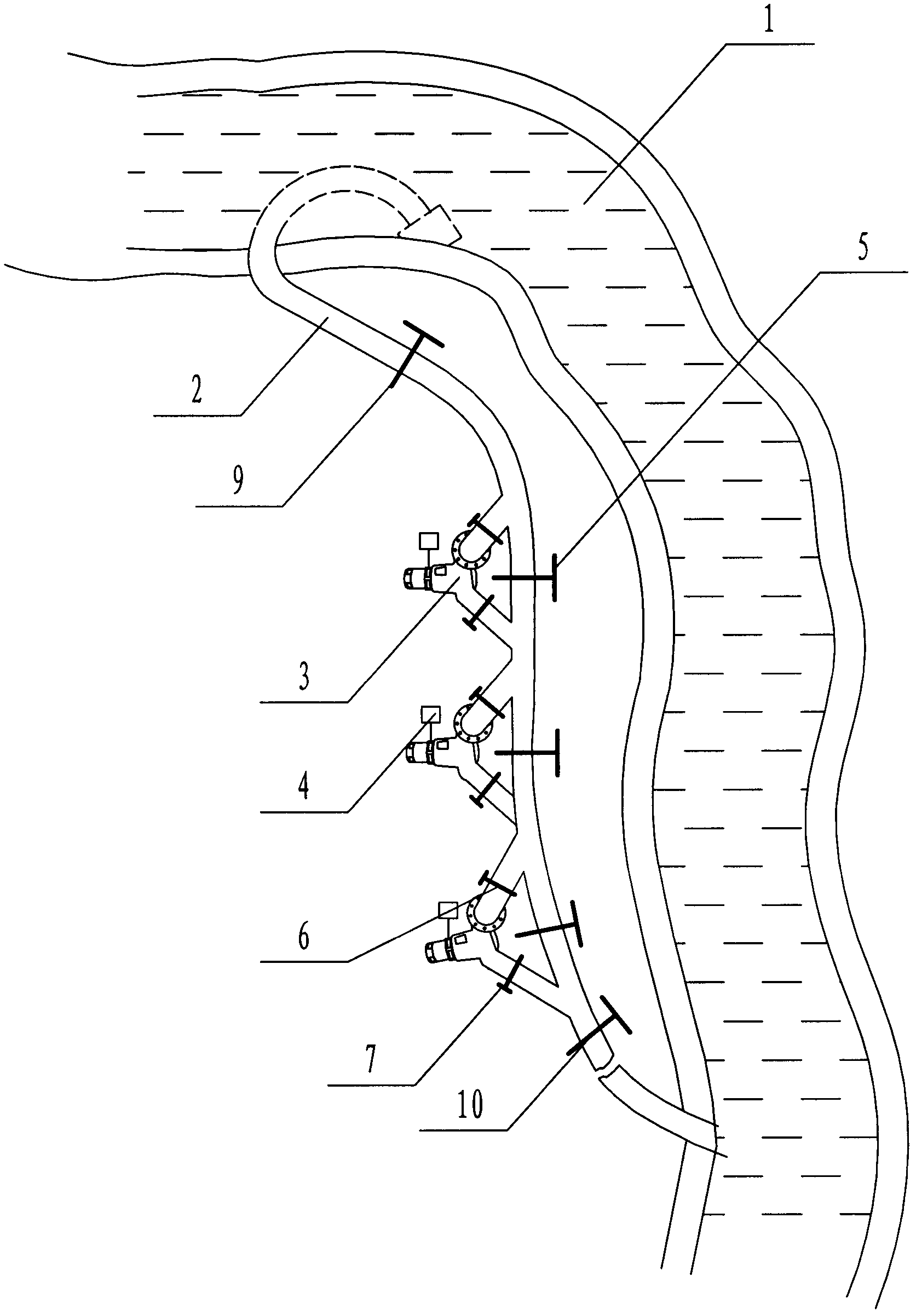

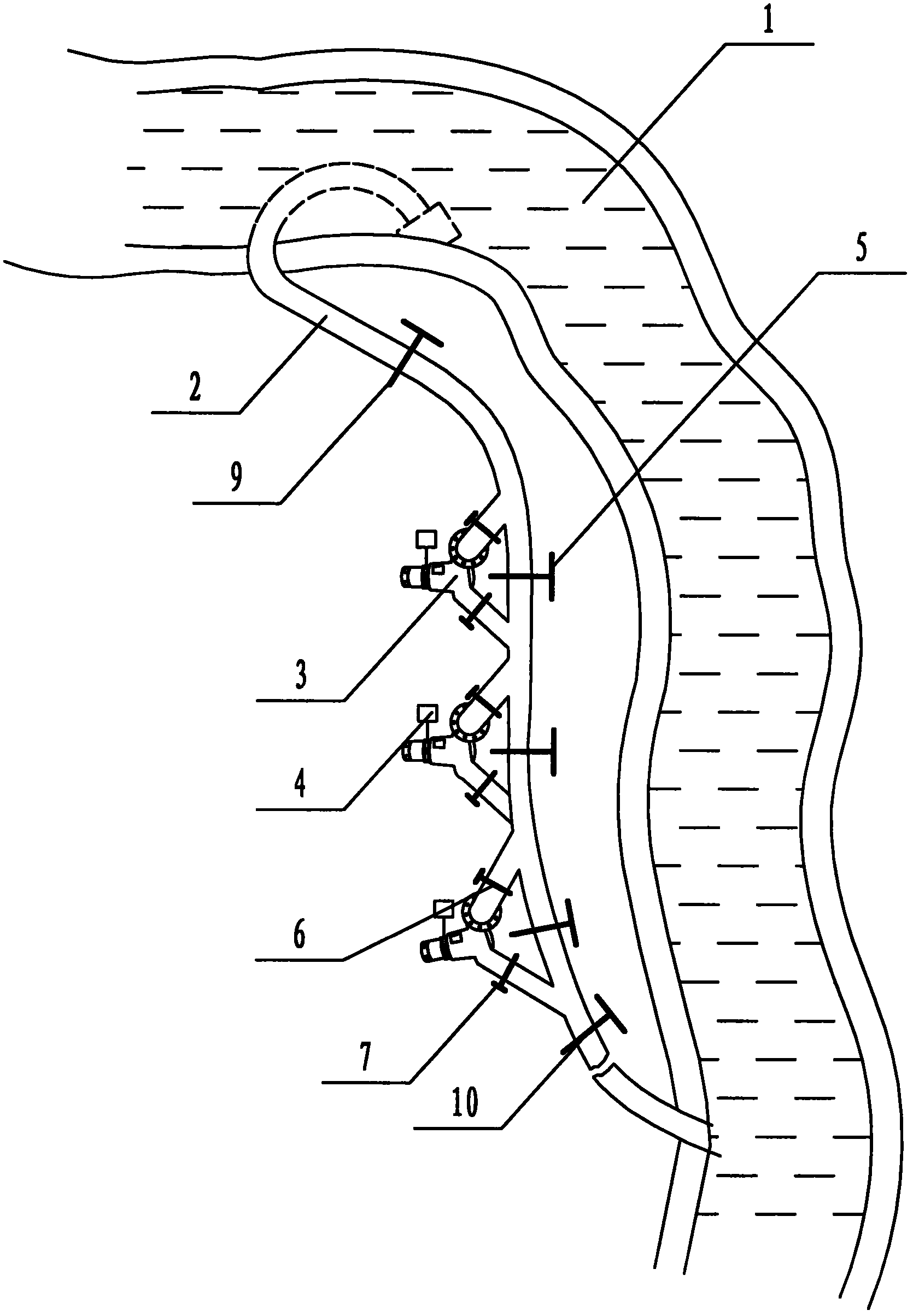

[0024] As attached figure 1 As shown, the siphon-type multi-stage hydroelectric power generation method of the present invention first selects a section of the river basin 1 with a water flow drop, and installs the water inlet end of the siphon pipe 2 in the upper water area of the water flow drop. The water flow drop section is laid, and the water outlet end of the siphon pipe 2 is introduced into the lower water area of the water flow drop section or other discharge places; a set or a set of pipe sections where the water flow pressure difference of the siphon pipe 2 reaches the power generation speed requirements of the hydro-generator set In the above-mentioned hydro-electric generator sets 3, each hydro-electric generator set 3 is connected to the parallel control system 4. The parallel control system 4 includes a flow control unit, a flow rate control unit, and a pressure difference control unit. The control units work in coordination to make the hydraulic turbine gener...

Embodiment 2

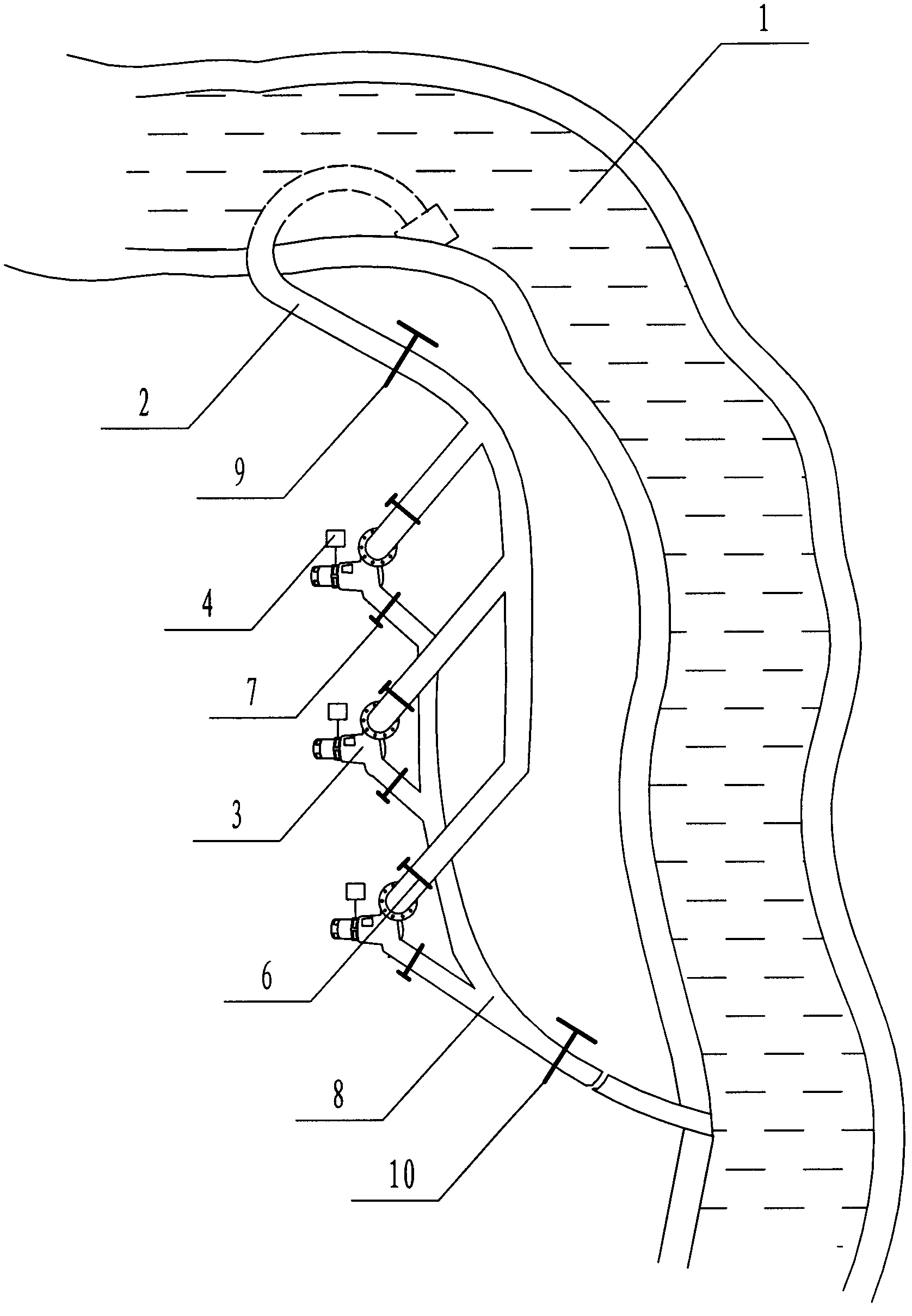

[0027] As attached figure 2 As shown, the siphon-type multi-stage hydroelectric power generation method of the present invention first selects a section of the river basin 1 with a water flow drop, and installs the water inlet end of the siphon pipe 2 along the upper water area of the water flow drop section. Following the laying of the water flow drop section, the water outlet end of the siphon pipe 2 is introduced into the lower water area of the water flow drop section or other discharge places; a set of pipe sections or pipe sections where the water flow pressure difference of the siphon pipe 2 reaches the power generation speed requirements of the hydro-generator unit 3 There are more than one group of hydroelectric generator sets 3, and each hydroelectric generator set 3 is connected to the parallel control system 4. The parallel control system 4 includes a flow control unit, a flow rate control unit, and a pressure difference control unit. The control units work in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com