Supporting walking system for heavy transportation machinery

A kind of transportation machinery, heavy-duty technology, applied in transportation and packaging, walking mechanism, load hanging components and other directions, can solve the problem of high strength requirements of running wheels, instability of transportation machinery, gnawing of rails, etc., to achieve large bearing capacity, avoid The effect of gnawing rails and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing embodiment:

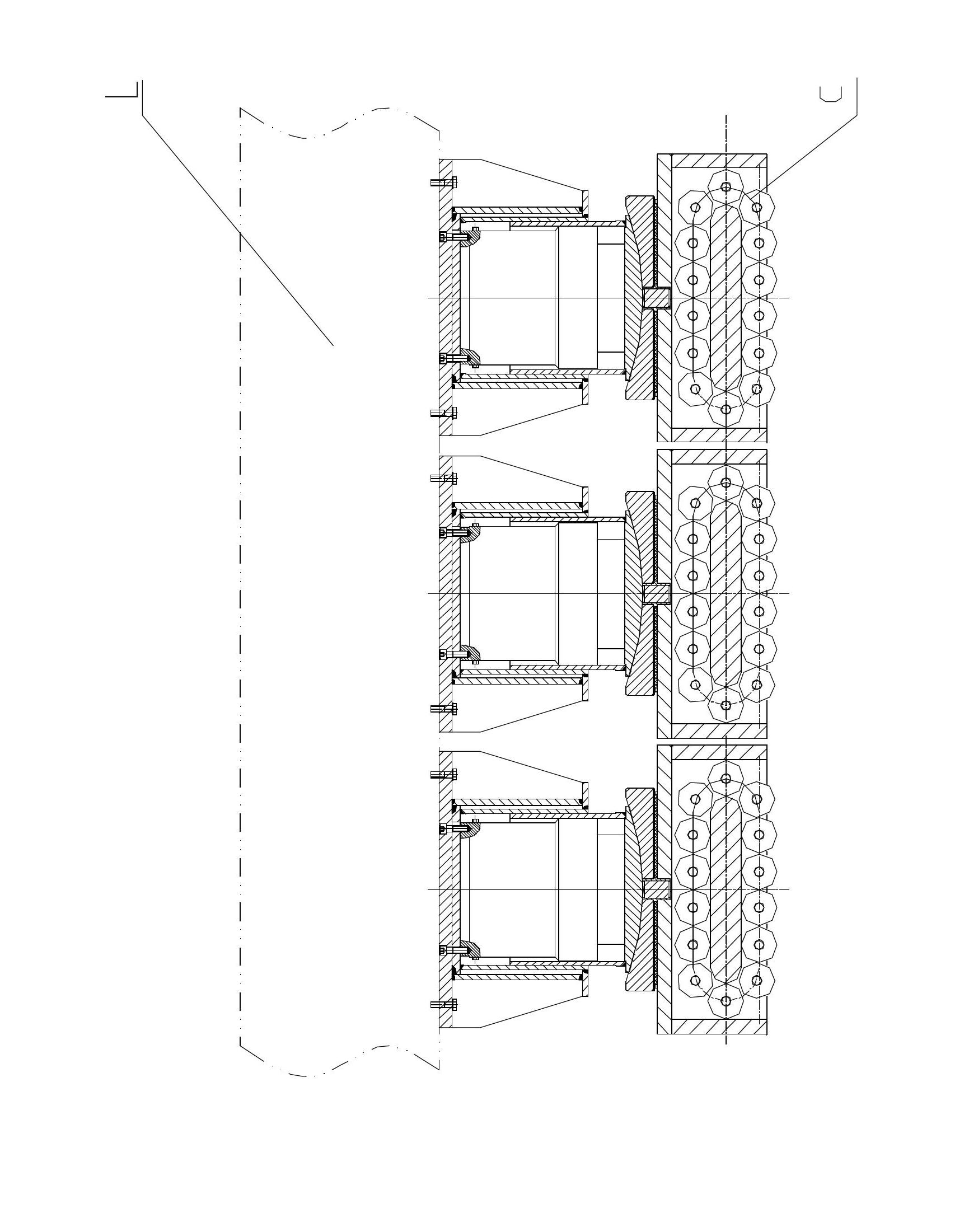

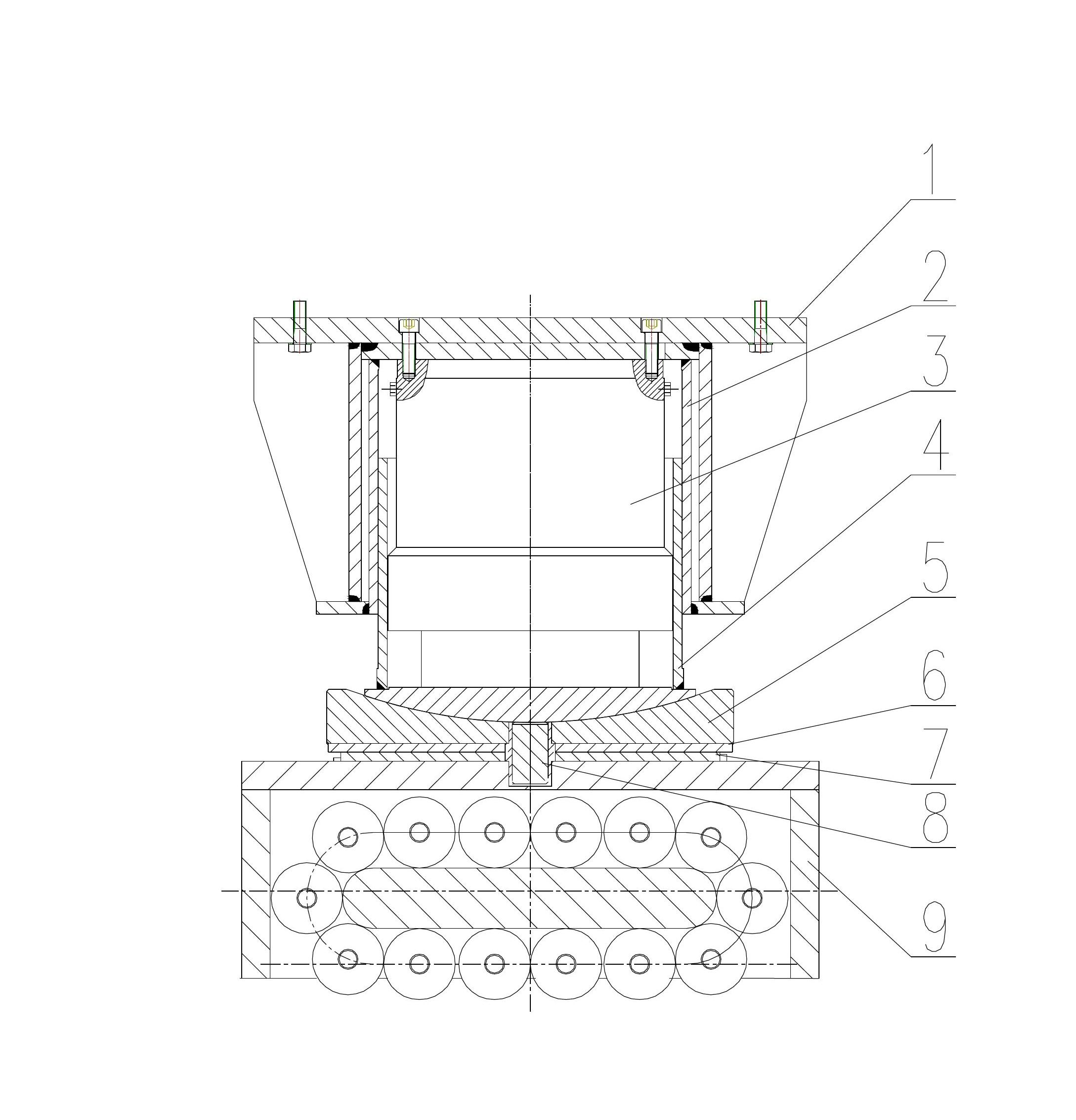

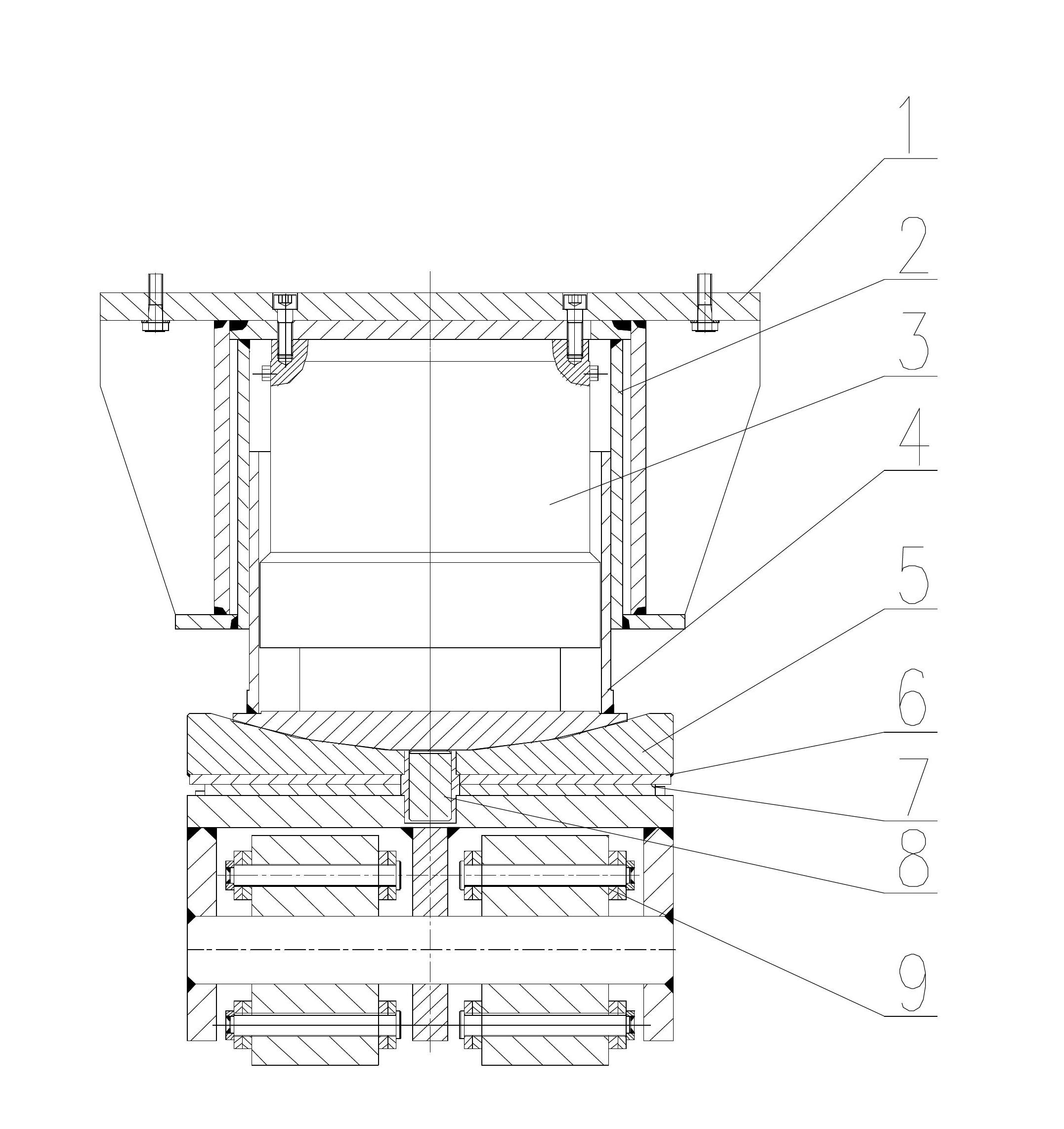

[0016] Such as figure 1 As shown, the traveling support system is composed of a hydraulic control system and a supporting traveling trolley. Multiple supporting traveling trolleys are connected in series and installed on the lower beam of the lifting and transporting equipment through bolts. The top of the guide cylinder 2 and the fixed end of the oil cylinder 3 of the supporting trolley are installed in the support through the countersunk bolts, and the stainless steel plate 6 is welded at the bottom of the ball joint seat 5, and polytetrafluoroethylene is added under the stainless steel plate 6. Vinyl plate 7, then the ball hinge seat 5 is installed on the upper surface of the roller cart 9 through the shear pin 8; The seat 5 is hinged. Such as figure 2 , 3 shown. The inner cavity of the support, the inner surface of the guide cylinder, and the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com