Manufacturing method for manual patch of heat insulating layer of filament winding engine shell

A technology for an engine casing and a manufacturing method, which is applied in the directions of lamination auxiliary operations, chemical instruments and methods, lamination, etc. The effect of sticking and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

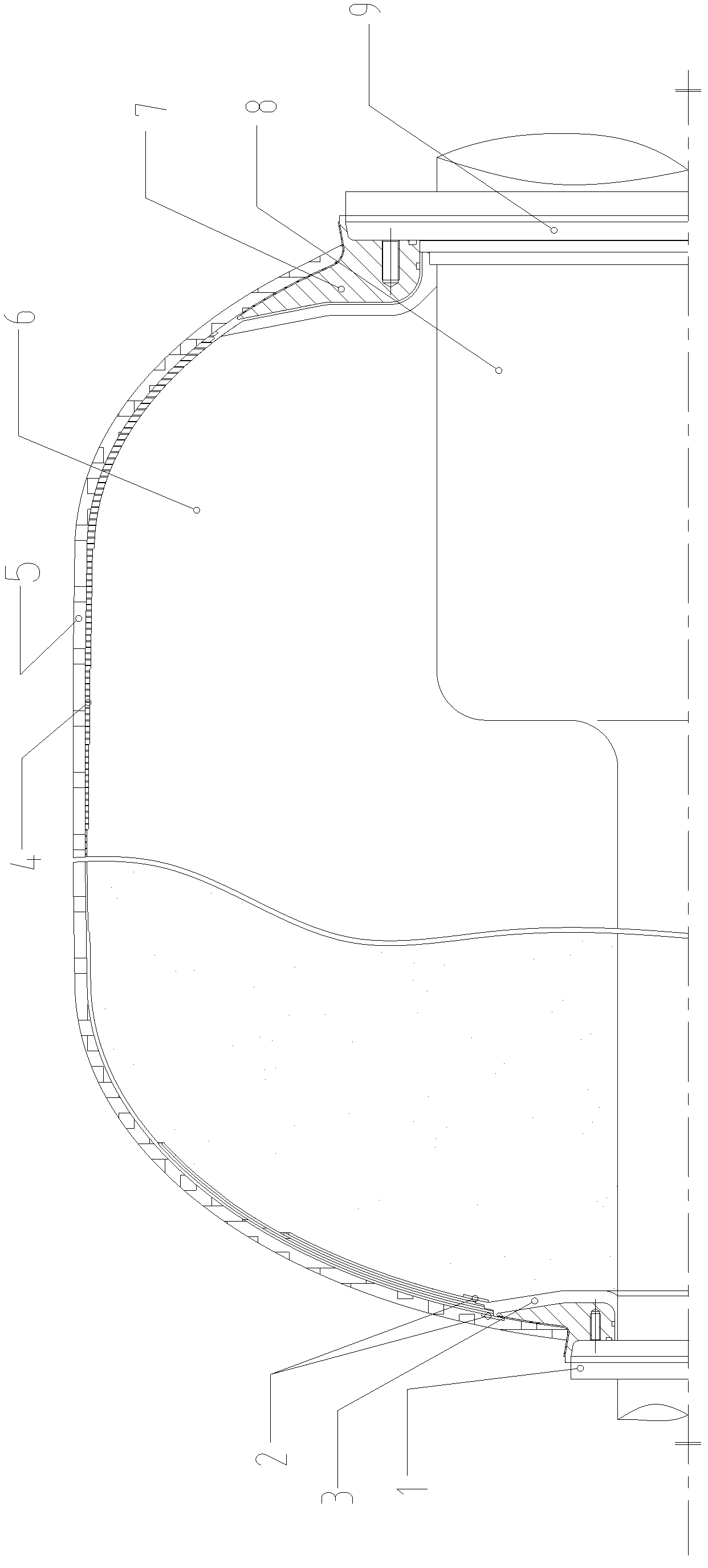

Image

Examples

Embodiment 1

[0038] The method for making the manual patch of the present invention comprises the following steps:

[0039] 1) Adjust the ambient temperature of the manual patch insulation layer to 25°C and the relative humidity to 70%;

[0040] 2) Clean up the dust on the surface of the gypsum mandrel 6 used for engine casing molding, wrap a layer of polytetrafluoroethylene paper on the middle straight section of the gypsum mandrel 6, and fix the end of the polytetrafluoroethylene paper to the gypsum mandrel 6;

[0041] 3) Brush the silicone rubber release agent 3 times on the surface of the two ends of the gypsum mandrel 6 other than the polytetrafluoroethylene paper and dry it;

[0042] 4) Grinding the bonding parts of the hand-patched thermal insulation layer 4 on the molded part 3 of the front joint and the molded part 7 of the rear joint, cleaning them with alcohol and drying them;

[0043] 5) Insert the front joint molded part 3 and the rear joint molded part 7 into the mandrel 8, ...

Embodiment 2

[0057] The method for making the manual patch of the present invention comprises the following steps:

[0058] 1) Adjust the ambient temperature of the manual patch insulation layer to 23°C and the relative humidity to 60%;

[0059] 2) Clean up the dust on the surface of the gypsum mandrel 6 used for forming the engine casing, wrap a layer of nylon paper on the middle straight section of the gypsum mandrel 6, and fix the end of the nylon paper to the gypsum mandrel 6;

[0060] 3) Brush the PMR release agent twice on the surface of the two ends of the gypsum mandrel 6 other than the nylon paper and dry it;

[0061] 4) Grinding the bonding parts of the hand-patched thermal insulation layer 4 on the molded part 3 of the front joint and the molded part 7 of the rear joint, cleaned with acetone and dried;

[0062] 5) Insert the front joint molded part 3 and the rear joint molded part 7 into the mandrel 8, use the front joint positioning tool 1 and the rear joint positioning tool 9...

Embodiment 3

[0076] The method for making a manual patch of the present invention comprises the following steps

[0077] 1) Adjust the ambient temperature of the manual patch insulation layer to 28°C and the relative humidity to 50%;

[0078] 2) Clean up the dust on the surface of the gypsum mandrel 6 used for engine casing molding, wrap a layer of polytetrafluoroethylene paper on the middle straight section of the gypsum mandrel 6, and fix the end of the polytetrafluoroethylene paper to the gypsum mandrel 6;

[0079] 3) Brush the silicone rubber release agent 3 times on the surface of the two ends of the gypsum mandrel 6 other than the polytetrafluoroethylene paper and dry it;

[0080] 4) Grinding the bonding parts of the hand-patched thermal insulation layer 4 on the molded part 3 of the front joint and the molded part 7 of the rear joint, and cleaning and drying with ethyl acetate;

[0081] 5) Insert the front joint molded part 3 and the rear joint molded part 7 into the mandrel 8, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com