Plate strip straightening equipment and precision adjusting method thereof

A strip and straightening technology, applied in the field of strip straightening equipment and its precision adjustment, can solve the problems of inevitable work roll surface wear, pitting, and backup roll damage, and eliminate edge and middle wave defects. , The effect of improving the quality of the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation. Of course, the following examples should not be construed as limiting the present invention.

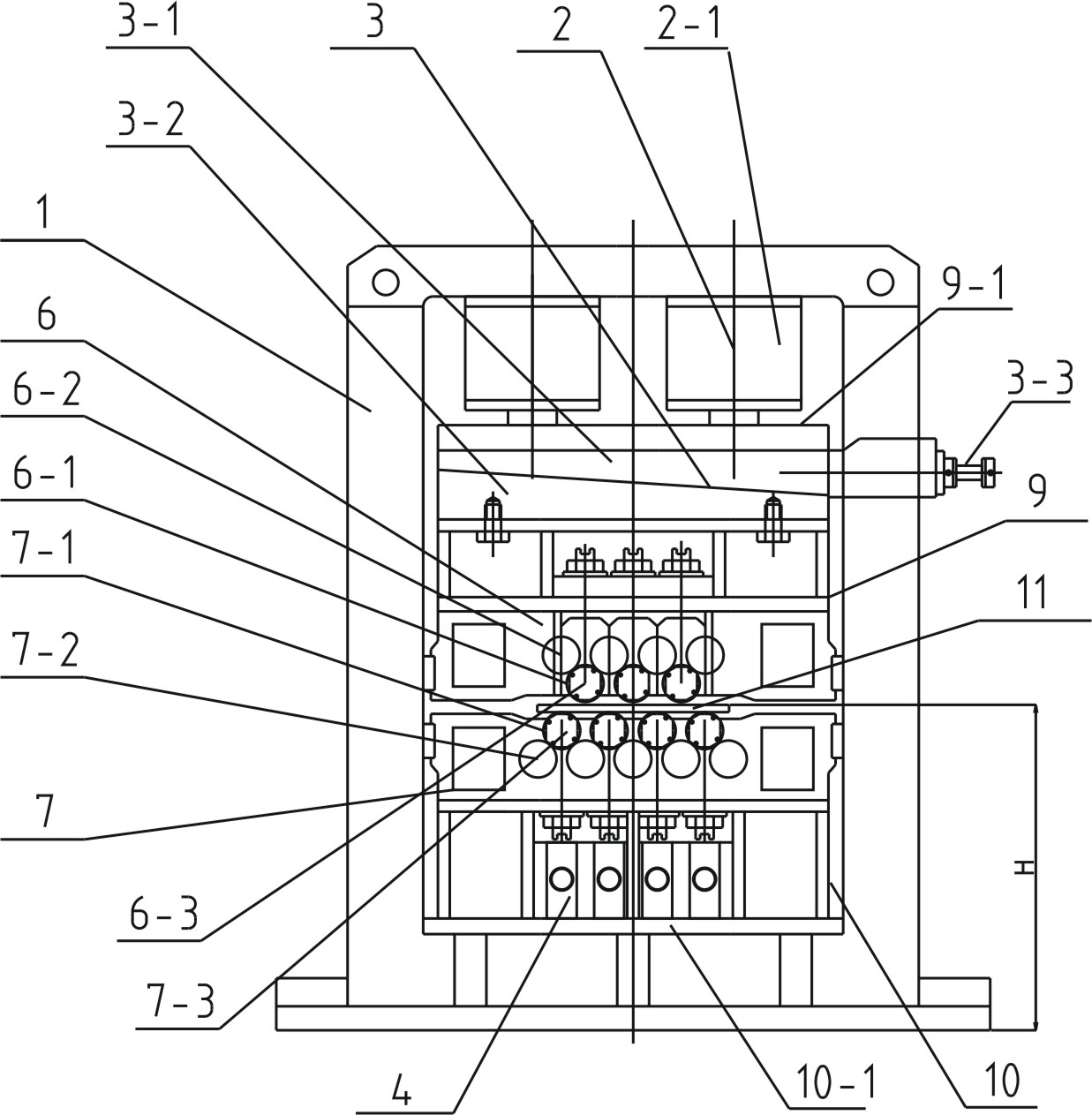

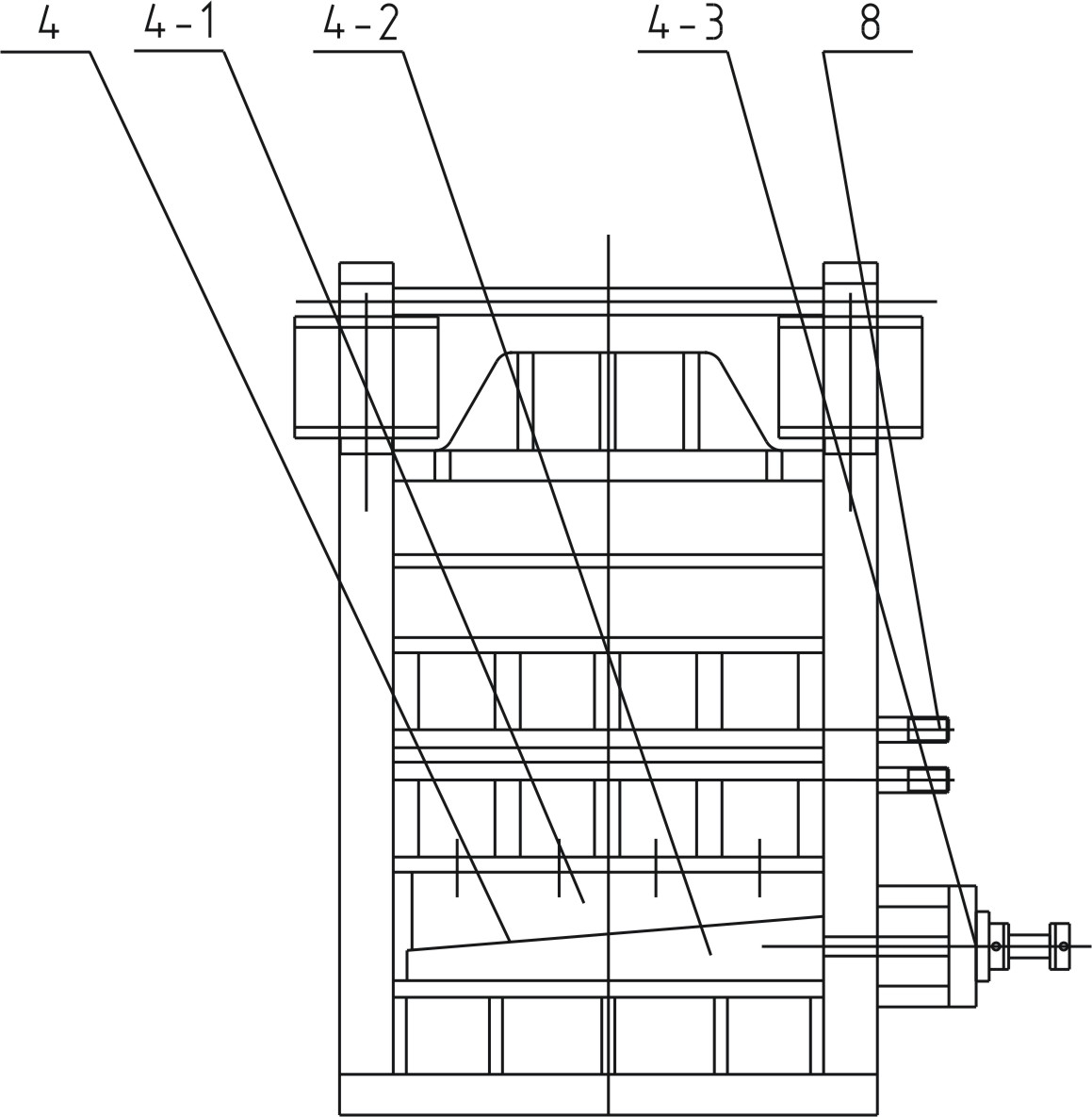

[0024] like figure 1 and figure 2 As shown, it is a kind of strip straightening equipment provided by the embodiment of the present invention, which includes a frame 1, a main pressing device 2, a working roll set, a backup roll set, a roll seat, an upper wedge adjustment device 3, four A lower wedge adjustment device 4, a transmission mechanism 8, an upper casing 9, and a lower casing 10.

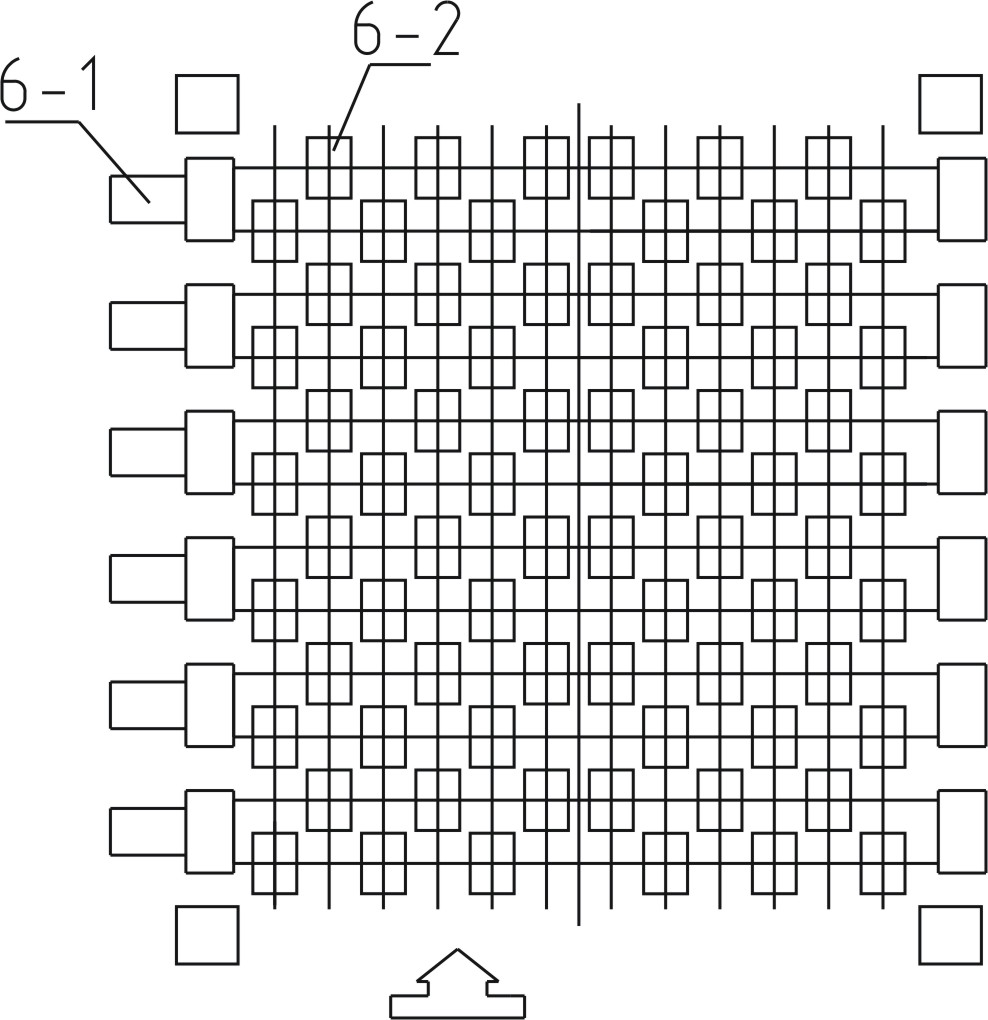

[0025] The work roll set includes an upper work roll set 6-1 and a lower work roll set 7-1 arranged alternately with the upper work roll set 6-1. In this implementation, the upper working roll set 6-1 includes three upper working rolls, and the lower working roll set 7-1 includes four lower working rolls. The support roller set includes an upper support ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com